Lets keep this thread to member builds of their ground mount either home-made, store bought or Frankenstein.

No questions or comments on the setup, just members post their mounts only with details below. I want a thread where people can scroll through everyone's post/pictures and see what their setup is and get ideas what might work for them instead of searching for days at every thread. If you have questions or comment about a build, message the member directly. I (and probably other people too) just want to scroll down and see the setups. Just hit the Like button and that is all. Please no comments or questions.

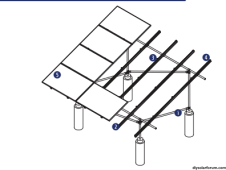

4-6 Picture of Overall ground mount completed, picture with some panels on but still being added so we can see the mounts/bracing under the panels, how it's anchored into ground (concrete, screw anchor, wires, etc..), picture behind the panels. pictures of how the vertical posts are connected to panel posts (some people use lags, u-bolts, etc..) We don't need overloaded with every single angle and every nut and bolt. This is just to give a "tease" so if someone likes your setup, we can message directly and get more information.

Thanks for playing!!

No questions or comments on the setup, just members post their mounts only with details below. I want a thread where people can scroll through everyone's post/pictures and see what their setup is and get ideas what might work for them instead of searching for days at every thread. If you have questions or comment about a build, message the member directly. I (and probably other people too) just want to scroll down and see the setups. Just hit the Like button and that is all. Please no comments or questions.

Details of your ground mount system including some detail about your setup. EX. - total KW size of ground mount built for, overall dimensions, what size ground contact posts you used (PT, Poles, I-beam...) Costs to build and maybe a picture if you did something unique (single axis, adjustable, etc..), your location (Canada vs FL will have an impact on design), what manufacture you purchased from if store bought

4-6 Picture of Overall ground mount completed, picture with some panels on but still being added so we can see the mounts/bracing under the panels, how it's anchored into ground (concrete, screw anchor, wires, etc..), picture behind the panels. pictures of how the vertical posts are connected to panel posts (some people use lags, u-bolts, etc..) We don't need overloaded with every single angle and every nut and bolt. This is just to give a "tease" so if someone likes your setup, we can message directly and get more information.

Thanks for playing!!