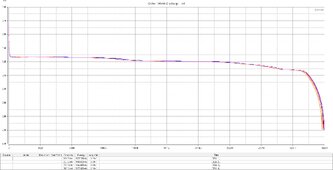

I recently purchase four Gotion 340Ah LFP cells and because of scepticism on the forum about their true capacity, decided to fully test all four using an EBC-A20. Please refer to the attached files for complete results but simply, the tested normalised capacities were as follows:

Cell 1: 366Ah

Cell 2: 365Ah

Cell 3: 364Ah

Cell 4: 367Ah

Overall, very happy with the purchase.

Notes:

1. The EBC-A20 can only discharge at 20 amps (0.06C) rather than at 0.2C so the results are probably, a little optimistic.

2. The EBC-A20 calculates the capacity using average voltage rather than the industry accepted testing value of 3.2 so the above capacities have been normalised.

3. The EBC-A20 was voltage calibrated at 2.50 and 3.65 volts and monitored with a 22000 count DMM. Voltage difference between the EBC-A20 and DMM throughout testing was a maximum of 10 mV.

4. The alligator clips on the end of the EBC-A20 leads were replaced with M6 ring terminals to ensure a better battery connection.

5. The cells were purchased from www.tewaycell.com and came with four, high quality, flexible copper bus bars which are sized to fit the wider Gotion cells as standard ones are too small.

6. The Simplified Data spreadsheets have had the initial and final charge data removed which has caused a very minor error in the data presented at the bottom of the Combined Curve. Refer to the Complete Data spreadsheets for accurate discharge energy values.

Cell 1: 366Ah

Cell 2: 365Ah

Cell 3: 364Ah

Cell 4: 367Ah

Overall, very happy with the purchase.

Notes:

1. The EBC-A20 can only discharge at 20 amps (0.06C) rather than at 0.2C so the results are probably, a little optimistic.

2. The EBC-A20 calculates the capacity using average voltage rather than the industry accepted testing value of 3.2 so the above capacities have been normalised.

3. The EBC-A20 was voltage calibrated at 2.50 and 3.65 volts and monitored with a 22000 count DMM. Voltage difference between the EBC-A20 and DMM throughout testing was a maximum of 10 mV.

4. The alligator clips on the end of the EBC-A20 leads were replaced with M6 ring terminals to ensure a better battery connection.

5. The cells were purchased from www.tewaycell.com and came with four, high quality, flexible copper bus bars which are sized to fit the wider Gotion cells as standard ones are too small.

6. The Simplified Data spreadsheets have had the initial and final charge data removed which has caused a very minor error in the data presented at the bottom of the Combined Curve. Refer to the Complete Data spreadsheets for accurate discharge energy values.