1.1-1.5v are likely okay but better to initially charge at < 0.5 amp until they reach greater then 2.5v. When a LFP cell is left for extended time at less than 1v it will grow lithium metal dendrites. These grow like needles that can punch through the separator creating cell shorts. By starting out with low current you do two things. If there are leakage shorts, too much charging current will heat up cell and can cause them to burst and vent. If with low charging current the cell voltage does not rise you can be fairly sure it has some leakage shorts and should be discarded.

The fastest way to check cells is to check their terminal voltage slump after about two minutes of load. Charge them to mid state of charge so their rested (rested no load for about 5 minutes after charging) state voltage is about 3.30 vdc.

Get a iDST BattGO device that will measure 8 series connected cells simultaneously. Use two iDST monitors if doing a 16s configuration.

You will need to be able to apply a load current of between 0.2 to 0.4 CA, 32 to 64 amps for a 160 AH cell. You can use inverter to provide load.

With at least 50% state of charge, measure and record each open circuit rested voltage on each cell. Then turn on the 0.2-0.4 CA load. You are going to wait two to three minutes and record the loaded voltage on each cell. The slump has an exponential decay so it will drop quickly at first then slowly level off. When you start the load if a cell drops greater than 0.5v from OCV too quickly, just stop load and replace the cell that drops too quickly. That is a bad cell.

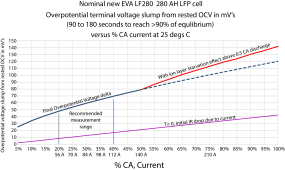

The more used a cell is, the greater the terminal voltage slump will be with load after two minutes of applied load when cell reaches equilibrium for given load current.

The chart below represents a new cell for an EVA 280 AH. The cells you have are similar thickness electrode design, just lower AH capacity. A used but still useable cell can be 3 to 5 times the slump voltage shown in this chart. Should match series connected cells that have same amount of terminal voltage slump for same amount of load current. The greater the voltage slump, the lower the cell's remaining AH capacity and poorer the condition of cell.

If you want to run AH discharge curves, First try a cell with worse terminal voltage slump. It will have the lowest AH capacity.

View attachment 70113

.