I am starting the final assembly of my packs. What is the best method to secure the packs together? I have not welded them yet with battery-hookup fused cells yet. Picking the holders up with the batteries installed it is flimsy and tends to come apart. Any suggestions?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to secure 18650 holders

- Thread starter Jonk8id

- Start date

OffGridInTheCity

Solar Wizard

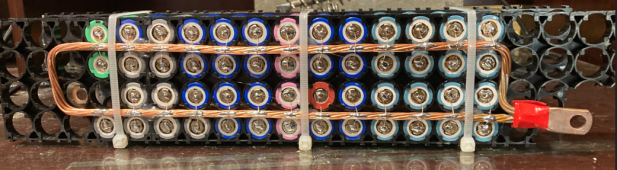

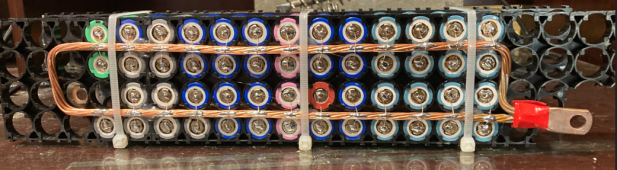

I use twist-ties around the packs to make them pretty rigid / easy to pickup and handle. The one in this pic is ~50p, weighs 5lbs, and has 130ah capacity.

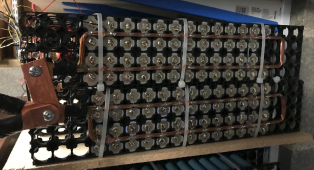

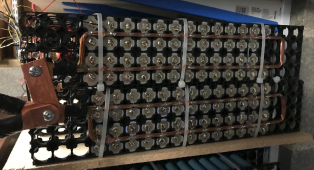

and twist-ties to secure multiple 'base packs' into a larger packs. This 8 cell high double-pack is ~100p, weighs ~10lbs, and has 260ah of capacity.

A 14s100p (48v battery) weights ~140-150lbs.

and twist-ties to secure multiple 'base packs' into a larger packs. This 8 cell high double-pack is ~100p, weighs ~10lbs, and has 260ah of capacity.

A 14s100p (48v battery) weights ~140-150lbs.

Last edited:

OffGridInTheCity

Solar Wizard

I do inbetween. I solder the ends of the cells in 1st pass, then add the twist-ties, and then solder the fuse wire from cell to buss. This is minimum interference with the soldering iron but stabilizes the pack for the final fuse wire solder pass.So you tie them up after you weld/solder the bus bar. Thanks for the info. I have 80P packs.

In you're case you might be able to place the spot-weld sheets, then twist-tie for stability, then do the spot welds? Whatever works. I use 14" zip cables - https://www.amazon.com/gp/product/B00UUB73EK/ref=ppx_yo_dt_b_search_asin_title

You can always just cut them off if they don't work for you

OffGridInTheCity

Solar Wizard

From a long term powerwall persective..... I don't see value in pack level quick-disconnect. Also, my battery bank is designed to go up to 400a and depending on you're design (max load in the future), you might need really hefty (big $) connectors.Is it worth adding connectors so each battery so it could be unplugged manually or is it not worth the $$$$

I bolt together the series of 14 packs that make up a battery. Early on I disassembled (unbolted) my 1st 2 x 130ah 14s batteries to create 1 x 260ah 14s battery and it was just the reverse of the assembly. The 5 years since I've only added. Each shelf is a stand-alone 14s100p battery (~140lbs) and was assemble left to right on the shelf using the shelf to hold the weight. Takes 20-30min to bolt together 14 packs + a few mins more to parallel into the overall battery bank and hook up the Batrium longmons. Disassembly is similar - same amount of time.

Have finished 126 packs @ 260ah each to date for 121kwh powerwall. I expect this powerwall to sit/operate for at least 10 more years.

The 1st battery has 5yrs / 1,680 cycles and no noticeable degradation but the most recent 14s battery only has 111 cycles. When unacceptable degradation occurs (another 5 or 10 or ? years), I imagine I'll need to deal with the 14 packs of that battery as a whole (retire or replace) so quick-disconnect individual packs don't seem to have much advantage in my mind.

Last edited:

Thanks for the info. What do you set your charge voltage/cutoff voltage to. I am still in the processes of finding the best BMS for the price. I have a battery analyzer at work. When I get my first pack assembled I want to run it through some tests.

OffGridInTheCity

Solar Wizard

I'm off-grid with grid-assist on purpose to avoid grid-tie.Thanks for the info. What do you set your charge voltage/cutoff voltage to. I am still in the processes of finding the best BMS for the price. I have a battery analyzer at work. When I get my first pack assembled I want to run it through some tests.

My goal from the beginning is *long life* of the powerwall - as in 10, 20 years. After all, it's so much work to build this thing.

Thus, I'm ultimately shooting for 30% average DOD (purple line) but only down to 37% lifetime average DOD so far. I hope this will lead to LifePo4 type cycles - e.g. 6,000-8,000 cycles as shown in this famous Battery University Chart. Hope to prove the charge true!

Operating with 49.5v low (3.54v/cell) and 56v (4.0v/cell) hi. In the winter a typical cycles is 49.5v -> 51-52v hi. In the spring / summer I have enough PV to run 24/7 so it's typically 56v hi every day but only goes down to 52v by next morning. Thus, the overall operating range is 3.54v/cell <---> 4.0v/cell but the daily voltage range is a subset and varies depending on the time of year.

I've arrived at this range based on several local factors including max use of incoming PV, keeping a buffer above the discharge curve knee, long life, consumption profile of my home, and other factors.

You may decide on a different range - perfectly OK as you're situation is unique to you. However, in general, I would recommend staying within 58.1v (4.15v/cell) hi and 47.6v (3.4v/cell) low. The main reason is there just isn't much power from 4.15v/cell -> 4.2v/cell on the top end or 3.0v-3.4v on the lower end but you *greatly* add stress (shorter life) to the cells.

Last edited:

I was thinking 4.05 to 3.4V. I will be spot welding this weekend, and will test the packs using these limits. Then finding the right JK bms for my 14S system. my packs are made using 80 2600maH cells (actual 2550-2750 maH if you trust my xtar VC8Plus tester results)

Similar threads

- Replies

- 16

- Views

- 691

- Replies

- 7

- Views

- 470

- Replies

- 3

- Views

- 222