You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

JK BMS Current Consumption (JK-B2A8S20P-H)

- Thread starter drlucid

- Start date

Horsefly

Solar Wizard

I completely agree, but I'd go farther: Make the heat turn-on and turn-off temperatures items that can be set via the app.Have they changed the heating algorithm yet? The last I heard, it used the low temp cutoff for activating the heater. It would turn off the charge and turn on the heater. Then when the low temp recovery temp was reached, it turns off the heat and on the charge. I would much rather see a heat on temp that was a few degrees above the LTC so that it would prevent the charge cutoff.

hwse

Solar Enthusiast

- Joined

- Jan 2, 2021

- Messages

- 585

I made a suggestion to Nami about changing the programing but did not ever hear if they would or could change the programing. It would seem to me to be a simple thing but who knows. The way it is, it is not very useful. The idea of heating is to allow cold weather charging, but they have it set up to prevent cold weather charging. D'oh! ?That's the behavior of mine, but I have not attempted to perform any microcode updates subsequent to its arrival in early June.

Braingears

New Member

- Joined

- Sep 17, 2020

- Messages

- 23

Horsefly

Solar Wizard

RV10flyer

Solar Wizard

- Joined

- Mar 8, 2021

- Messages

- 1,198

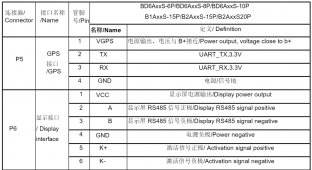

I'm using P5-1. If you measure that, you'll see the LCD is drawing 32mA (wired as 16S or 53.3V float) through that wire.I want to create a switch that turns on/off the LCD Display (that consumes 2W).

View attachment 105052

Which circuit should I put a switch on? P6-1?

Last edited:

RV10flyer

Solar Wizard

- Joined

- Mar 8, 2021

- Messages

- 1,198

I would just unplug all of my BMS connectors if I'm going to leave the battery set for three months.@Nami Is there a spec for current consumption in the various operating modes? My batteries will sit for several months with no charger input and I am concerned about 65mA continuous current.

How does the hardwired button that you can get with this model work? Can you use it to "disconnect" the BMS insitu so no power draw for storage. Then use the button to turn the BMS on? But I think all the BMS settings go back to default? Anyone able to clarify please.I would just unplug all of my BMS connectors if I'm going to leave the battery set for three months.

Aussie Collie

New Member

- Joined

- Dec 18, 2021

- Messages

- 27

The settings stay set, no issue there. I turned mine off with the button for two months and only lost 10% charge, which I think is within spec and normal for the cells (100ah/8s)How does the hardwired button that you can get with this model work? Can you use it to "disconnect" the BMS insitu so no power draw for storage. Then use the button to turn the BMS on? But I think all the BMS settings go back to default? Anyone able to clarify please.

Horsefly

Solar Wizard

From what I've seen, turning the JK BMS off preserves all the settings, but it starts over on figuring out the SoC. That is, it will take a few cycles before it can report anything close to the real SoC.How does the hardwired button that you can get with this model work? Can you use it to "disconnect" the BMS insitu so no power draw for storage. Then use the button to turn the BMS on? But I think all the BMS settings go back to default? Anyone able to clarify please.

RV10flyer

Solar Wizard

- Joined

- Mar 8, 2021

- Messages

- 1,198

Edit: Yes, that is correct about the button. Once you unplug it and plug it back in, you have to charge it up to your overvoltage parameter setting before it will read 100% SOC. This overvoltage setting can be whatever you want it to be. I have used 3.65V, but I've also lowered it to 3.45V do that I wouldn't have to take cells so high to reset to 100%.How does the hardwired button that you can get with this model work? Can you use it to "disconnect" the BMS insitu so no power draw for storage. Then use the button to turn the BMS on? But I think all the BMS settings go back to default? Anyone able to clarify please.

Last edited:

I would just unplug all of my BMS connectors if I'm going to leave the battery set for three months.

I'm aware I could unplug the BMS while the batteries are unused but the real issue is why do these BMS boards draw so much average current? I'm not sure what JK is using for an MCU and Battery Monitor but for example, the TI BQ76920 Battery Monitor IC draws around 120uA when it's active and a STM32L0 MCU in low power mode is around 8uA. It really seems like poor power management design for the BMS itself. A reasonable expectation for a BMS is to monitor and protect the battery cells continuously without being a significant load itself. Cordless tool manufacturers have BMS on 2Ah batteries that can sit for many months without any significant discharge. I realize that many stationary systems have regular charging and/or capacity of several hundred or thousand Ah but there is no acceptable reason for that much average current for a BMS.

It seems like there is a real need for an open source scalable BMS for the DIY community. Sourcing reasonably priced copper inlay PCBs for the MOSFET power path would be an issue that would need to be resolved for that to happen.

hwse

Solar Enthusiast

- Joined

- Jan 2, 2021

- Messages

- 585

I have seen open-source DIY BMS designs. Just not one that has a very well-functioning 2A active balancing.I'm aware I could unplug the BMS while the batteries are unused but the real issue is why do these BMS boards draw so much average current? I'm not sure what JK is using for an MCU and Battery Monitor but for example, the TI BQ76920 Battery Monitor IC draws around 120uA when it's active and a STM32L0 MCU in low power mode is around 8uA. It really seems like poor power management design for the BMS itself. A reasonable expectation for a BMS is to monitor and protect the battery cells continuously without being a significant load itself. Cordless tool manufacturers have BMS on 2Ah batteries that can sit for many months without any significant discharge. I realize that many stationary systems have regular charging and/or capacity of several hundred or thousand Ah but there is no acceptable reason for that much average current for a BMS.

It seems like there is a real need for an open source scalable BMS for the DIY community. Sourcing reasonably priced copper inlay PCBs for the MOSFET power path would be an issue that would need to be resolved for that to happen.

The LTC3300 seems like a good solution for active balancing that's not limited by internal FETs. The DC2100B-D eval board (LTC3300) supports 4A of active balancing. What were those open source designs using for the main power path switching?I have seen open-source DIY BMS designs. Just not one that has a very well-functioning 2A active balancing.

RV10flyer

Solar Wizard

- Joined

- Mar 8, 2021

- Messages

- 1,198

My JK's consume from 10 to 14 mA. The LCD consumes 32 mA. They are no different than my other seven brands of BMS's that I have used. It's really not that much power. Less than 1W.I'm aware I could unplug the BMS while the batteries are unused but the real issue is why do these BMS boards draw so much average current? I'm not sure what JK is using for an MCU and Battery Monitor but for example, the TI BQ76920 Battery Monitor IC draws around 120uA when it's active and a STM32L0 MCU in low power mode is around 8uA. It really seems like poor power management design for the BMS itself. A reasonable expectation for a BMS is to monitor and protect the battery cells continuously without being a significant load itself. Cordless tool manufacturers have BMS on 2Ah batteries that can sit for many months without any significant discharge. I realize that many stationary systems have regular charging and/or capacity of several hundred or thousand Ah but there is no acceptable reason for that much average current for a BMS.

It seems like there is a real need for an open source scalable BMS for the DIY community. Sourcing reasonably priced copper inlay PCBs for the MOSFET power path would be an issue that would need to be resolved for that to happen.

Last edited:

Similar threads

- Replies

- 0

- Views

- 119

- Replies

- 3

- Views

- 208

- Replies

- 1

- Views

- 303