miahallen

New Member

- Joined

- Dec 28, 2021

- Messages

- 25

Been doing solar for 9 years now, this is the first time I've seen a Lead Acid battery explosion. I would love some feedback as to the possible cause so I can avoid, and hopefully help others also avoid this scenario in the future.

I installed this system about 5 years ago, and it has been performing flawlessly for those 5 years, except for one wire which became corroded and was replaced about 2 years ago.

Last week, I got a call from the client telling me one of the batteries exploded (he was standing only 8-10ft away at the time. He described it as follows:

I installed this system about 5 years ago, and it has been performing flawlessly for those 5 years, except for one wire which became corroded and was replaced about 2 years ago.

Last week, I got a call from the client telling me one of the batteries exploded (he was standing only 8-10ft away at the time. He described it as follows:

- a hemisphere of plasma more than 1 inch in radius formed over the terminal of the battery

- He immediately began shutting the system down

- within about 20 seconds, the explosion occurred splattering acid on him

- He felt the burning of the acid on his face and immediately ran to the shower to wash

- the system was shut off for the past few days, till I was able to go assist yesterday

- the client is fine, no acid got in his eyes and he cleaned quickly, so no ill effects

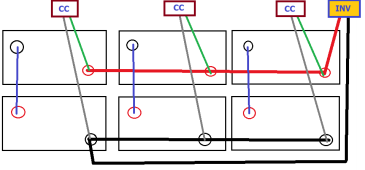

- 2S3P - 370AH Delta L16 deep cycle batteries - 12V

- 3x Flexmax80 charge controllers (each with enough PV to peak at about 80A output)

- 1x 3600W Flexpower inverter - 12V

- All battery interconnects are 2/0 pure copper, with copper ring terminals

- batteries were regularly serviced, and water kept topped up

- Even after the explosion, all 6 batteries were testing in the 6.05-6.10V range, including the exploded battery

- All battery interconnects tested at close to zero ohms of resistance

- the inverter and charge controllers are all still functional

- 2 batteries were replaced last year ( I did not do the work)

- I was not the last person to work on the system