This says outback is made in USA. It says rest are made in China:

"VICTRON, SMA, SCNEIDER, "

Granted this is advertising but suspect it is true. Read to many similar to it.

www.atlanticwastepower.com

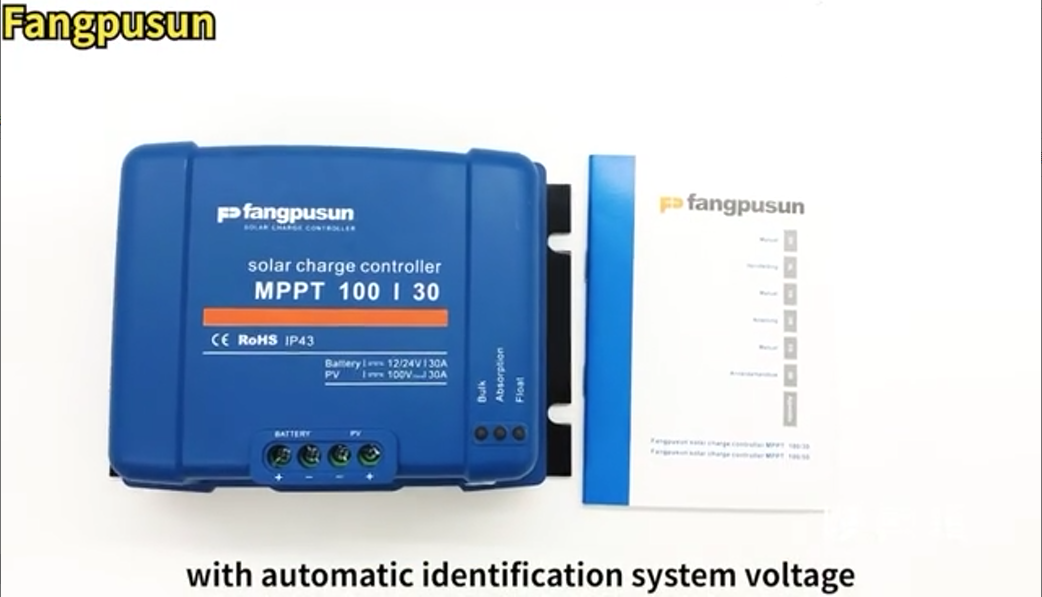

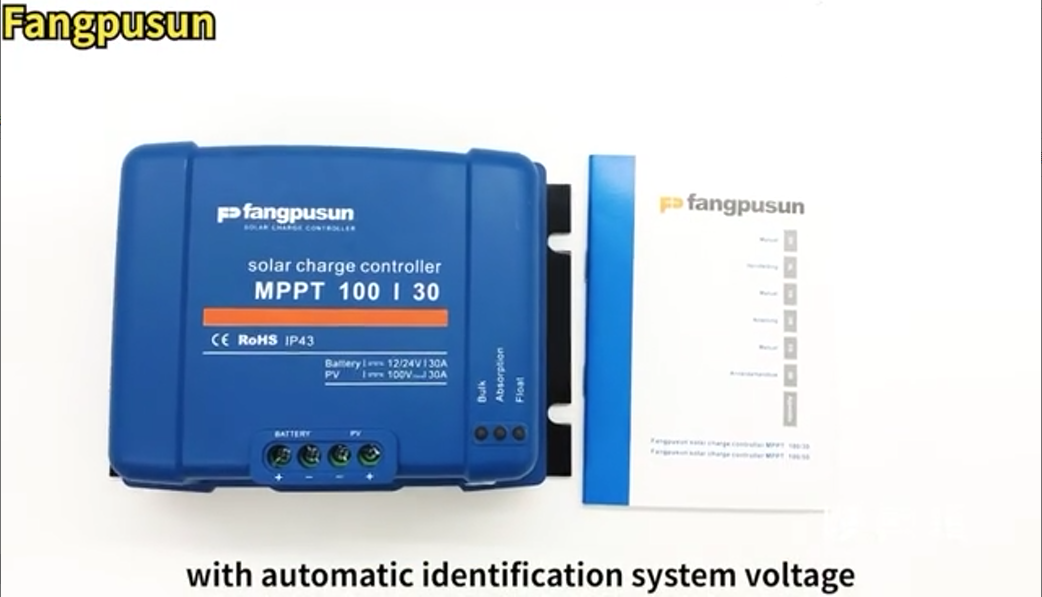

Sol-Ark is Deye from other sources. We see what appears to be a chinese offered Outback charge controller relabeled at similar pricing.. as well as victron. Did the patent run out?

Welding machines did the same thing several decades ago but did not want to lose Made in USA status. Miller Lincoln Hobart and so on as examples.

I find it funny when ppl say cheap Chinese junk because of origin. They unknowingly or knowingly had cheap Chinese labor but expensive prices because manufacturing had moved. Usually a dip in quality.

Victron should give a wire way for equipment ....they know it is problematic and as result will not honor warranty if burned up. They know this is problem area with their mppt. Why they made charge controller wireway - No?.

Crocodile tears. When the Chinese get a hold of something they do not like to improve it and there is normally dip in quality during transfer. Some due to displaced workers not caring some due to new ppl new setup for sourcing. Again decades ago welders did the same. They make interesting welders now. Still crazy expensive.

Example:

Post in thread 'Video that puts American vs Chinese solar manufacturing into perspective'

https://diysolarforum.com/threads/v...facturing-into-perspective.84793/post-1111247

What is funny are smug ppl that poo poo cheaper chinese made stuff but yet they paid more for Chinese made too. Time and time again. I was not aware that overly expensive Sol-Ark was DEYE until tried buy a USA Version of DEYE and told by Chinese exporter they could not sell $2000 range Deye because importer had Market locked up here. Sound like free open market from a Chinese origin company?

See Victron if made in China with cheaper labor then they need to spend some profit to improve the product. Like the rest….over priced. Victron have your Chinese workers improve your products spend some of your profits…for improvements. Get those junk green spring connectors out of the MP II 48/3000 inverter too. I can hardly believe they Victron got UL listing with that crap.

Ppl should complain. Brand loyalty gets you nothing. As a minimum the wire way for victron solar charge converters should be included with new purchases.

Generally when ppl try to talk about improvements and sourcing passionate ppl that paid to much dubbed big spenders get upset. Yet they poo poo other chinese products without knowing source of their own. Victron needs to fix their crap cheap terminals and offer the strain relief foe wiring as stated in their manual with the factory produced wire way as sold separate by victron.

If the labor is cheap then improve the product especially since there is a remedy but wait they can sell a product to improve the quality vs giving one with each new product. Hahaha

It is cheap injected molded plastic….. ~$30+ dollars vs giving one away with each new purchase as product improvement. Why lose ~$30. Well 1 reason is if it solves terminals being burned up then it would stop products being talked about in “negative wire way box.” Cheap injection molding probably add a dollar to production cost to improve their own product “IF IT WORKS’’.

The former communist and former capitalist can charge extra ~$30 for a so called product improvement. Only way things get changed is if ppl complain….the company loses money. Money talks. Cheap affordable plastic injection molding should be included each new mppt at NO COST TO CUSTOMERS. PRODUCT IMPROVEMENT FOR VICTRON KNOWN FAULT.

www.epever.com

www.epever.com

www.pvsolartech.com

www.pvsolartech.com

www.pvsolartech.com

www.atlanticwastepower.com

www.atlanticwastepower.com

diysolarforum.com