You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

MRBF or class T

- Thread starter APhoton

- Start date

Steve_S

Offgrid Cabineer, N.E. Ontario, Canada

I run 24V, 4000W (12,000W Max Surge) LF Samlex Inverter/Charger.

The Battery Bank is 2x 24V/174AH & 3x 24V/280AH, all are fused with 200A-MRBF at the Busbar.

Note that with 5 Packs that allows for 1000A collectively for output BUT 12,000W ÷ 25.2V = 476A, so it can never get there.

The Battery Bank is 2x 24V/174AH & 3x 24V/280AH, all are fused with 200A-MRBF at the Busbar.

Note that with 5 Packs that allows for 1000A collectively for output BUT 12,000W ÷ 25.2V = 476A, so it can never get there.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,564

I would assume lithium battery can deliver 20,000A into a short. You can compute that resistance, add resistance of cables (assuming not going to short near battery), determine fuse AIC requirement.

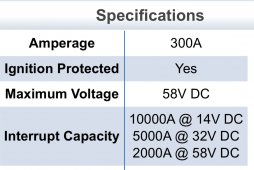

MRBF only 5000 AIC at 32V

www.bluesea.com

www.bluesea.com

I suppose 250A takes care of starting surge. These don't have delay.

Make sure you don't blow it with capacitor inrush, use a precharge resistor.

Curve shows 200% of rating 0.2 seconds, 120% of rating several seconds.

MRBF only 5000 AIC at 32V

MRBF Terminal Fuse - 250A - Blue Sea Systems

Space-saving ignition protected fuse for 30 to 300 Amp loads. Must use with Terminal Fuse Block.

I suppose 250A takes care of starting surge. These don't have delay.

Make sure you don't blow it with capacitor inrush, use a precharge resistor.

Curve shows 200% of rating 0.2 seconds, 120% of rating several seconds.

OzSolar

Whatever you did, that's what you planned.

Someday someone will provide something other than thier opinion about the Asymmetrical Fault Current we need to design for.

ianganderton

Auckland, NZ

The answers so far aren’t the easiest to understand considering this post is in the beginners forum

OzSolar

Whatever you did, that's what you planned.

An therein lies the crux of the matter. We are talking about systems that when fail will create enough heat to burn themselves into nothing along with all of the things around them until all of stored energy is gone.The answers so far aren’t the easiest to understand considering this post is in the beginners forum

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,564

Someday someone will provide something other than thier opinion about the Asymmetrical Fault Current we need to design for.

Educated opinion or SWAG. I am going by the reported measured IR of LiFePO4 cells, 0.17 milli-ohm.

Measured fault current is what we need. But I don't think it will exceed the figure I'm using, so that is safe for designing to.

Anybody feel like shorting their battery through a 1000A shunt, maybe get 1V drop across it?

Scope trace could capture the waveform, current interrupted shortly thereafter by a fuse.

I've seen a reported measurement of 4000A for 100 Ah AGM.

My calculation for typical starting battery, based on cranking amps, is 3000A.

I feel good relying on 20,000A figure for LiFePO4 cells.

Only so many fuse types to consider, place your bet and take your chances.

ianganderton

Auckland, NZ

From hereHi, on a 24V system with 3000W inverter and 280ah battery, can I use a 300a MRBF terminal fuse or should I use a 250a Class T fuse. I prefer the MRBF but what to be safe without going over board

DC Fuse and breaker Sizing and Placement

To get the paper, click on the orange button at the top of the page. The attached presentation gives the fundamentals for picking fuse/breaker sizes and describes where in the circuit they should be placed. You can download the presentation...

“The Amperage Interrupt Capacity (AIC) must be high enough for the Max Short Circuit Current. For LiFePO4 the short

circuit current can be verry high (>>10,000A). Note that for a main battery fuse on a battery, a Class T fuse is usually

the proper choice. There are breakers with very high AIC but they can be very expensive.”

MRBF specs from here

MRBF Terminal Fuse - 300A - Blue Sea Systems

Space-saving ignition protected fuse for 30 to 300 Amp loads. Must use with Terminal Fuse Block.

Thanks everyone for the quick response. As always more information would be helpful. I'm going to be using 2/0 awg wire with a total length of no more than 8 feet(positive and negative wire combined). MRBF would be on terminal connector at positive of battery. Not that I'm going to use MRBF I just trying to determine what is acceptable and appropriate for my camper

Last edited:

exactly, but where does beginner start and endThe answers so far aren’t the easiest to understand considering this post is in the beginners forum

Here is what I use - https://www.amazon.com/Midnite-Solar-MNEDC175-Panel-Breaker/dp/B00SGGVPTK

Not cheap but has 50,000 AIC rating and allows me to turn on/off my batteries easily.

Not cheap but has 50,000 AIC rating and allows me to turn on/off my batteries easily.

chess-equality

Solar Enthusiast

- Joined

- May 21, 2022

- Messages

- 500

Here is what I use - https://www.amazon.com/Midnite-Solar-MNEDC175-Panel-Breaker/dp/B00SGGVPTK

Not cheap but has 50,000 AIC rating and allows me to turn on/off my batteries easily.

But I think this breaker is AC and not DC?

Edit: It's VDC

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,018

any recommendations for a 1000A shunt and a contactor that would tolerate closing onto a short? ? i have wanted to *safely* test this for a while. the previous closest test i saw on this forum, someone used a decent length of like 6awg cable to provide a tempering reistance.Educated opinion or SWAG. I am going by the reported measured IR of LiFePO4 cells, 0.17 milli-ohm.

Measured fault current is what we need. But I don't think it will exceed the figure I'm using, so that is safe for designing to.

Anybody feel like shorting their battery through a 1000A shunt, maybe get 1V drop across it?

Scope trace could capture the waveform, current interrupted shortly thereafter by a fuse.

I've seen a reported measurement of 4000A for 100 Ah AGM.

My calculation for typical starting battery, based on cranking amps, is 3000A.

I feel good relying on 20,000A figure for LiFePO4 cells.

Only so many fuse types to consider, place your bet and take your chances.

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,018

internal resistance of pack, voltage, resistance of other componentsOK, that leads me to my next question. How do you calculate your AIC rating/need?

i think

chess-equality

Solar Enthusiast

- Joined

- May 21, 2022

- Messages

- 500

MRBF or class T

In a parallel bank that already has a Class T before the inverter, is ANL ok for each battery before the busbar?

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,018

being exposed to concepts of ohm's law and battery pack internal resistance seem like good options.exactly, but where does beginner start and end

higher battery internal resistance means lower ampere/amp flow during a short condition

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,018

MRBF vs Class-T fuse,

i am also still grappling with this topic for LiFePO4 battery build.

the tentative conclusion for me is,

12V LFP? MRBF probably ok.

24V LFP? MRBF *maybe ok*

48V LFP? Class-T Definitely

the different cost in components is very important to me. class-t are generally almost 5-10x cost of MRBF. whether saving 30-50 usd per battery pack is worth the potentially reduced safety margin, i don't know. i want to use class-t on every individual pack, but the cost is indeed offputting.

i am also still grappling with this topic for LiFePO4 battery build.

the tentative conclusion for me is,

12V LFP? MRBF probably ok.

24V LFP? MRBF *maybe ok*

48V LFP? Class-T Definitely

the different cost in components is very important to me. class-t are generally almost 5-10x cost of MRBF. whether saving 30-50 usd per battery pack is worth the potentially reduced safety margin, i don't know. i want to use class-t on every individual pack, but the cost is indeed offputting.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,564

In a parallel bank that already has a Class T before the inverter, is ANL ok for each battery before the busbar?

Only if a short between positive and negative can't happen before the Class T.

The ANL should take care of a modest over-current, might just arc and burn with a dead short. So you want Class T in the circuit to interrupt that.

In other words, might be OK of good separation or insulation between positive and negative.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,564

any recommendations for a 1000A shunt and a contactor that would tolerate closing onto a short? ? i have wanted to *safely* test this for a while. the previous closest test i saw on this forum, someone used a decent length of like 6awg cable to provide a tempering reistance.

Here's a 500A shunt.

Maybe a big starter relay would be fine for the 10's of milliseconds before class T fuse blows.

Other hardware in the 100A or 200A range is rated for 200,000A fault currents (like AC disconnect switches.)

One of those might do the job too. Wonder what happens to their contacts as they slide from touching to fully closed, with current running.

What's interesting about this subject is that you see very little about in builds on internet, youtube, etc. I bet you'd have a hard time finding a build/diagram that shows the use of Class T fuse or even MRBF for that matter. Only thing I see is about sizing fuse/breaker and if they do mention fuse it is ANL or MEGA. I wonder whyMRBF vs Class-T fuse,

i am also still grappling with this topic for LiFePO4 battery build.

the tentative conclusion for me is,

12V LFP? MRBF probably ok.

24V LFP? MRBF *maybe ok*

48V LFP? Class-T Definitely

the different cost in components is very important to me. class-t are generally almost 5-10x cost of MRBF. whether saving 30-50 usd per battery pack is worth the potentially reduced safety margin, i don't know. i want to use class-t on every individual pack, but the cost is indeed offputting.

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,018

many documents/designs may be based on lead acid and have not been updated, is the rationale i usually attributeI wonder why

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,564

Hobbyists bolt things together, and they work. Success!

Even many engineers/developers aren't good at thinking through worst-case scenarios or breaking their own designs.

Need a process where others try that, both black-box and white-box.

Even many engineers/developers aren't good at thinking through worst-case scenarios or breaking their own designs.

Need a process where others try that, both black-box and white-box.

No, what I've was lifepo4 builds!many documents/designs may be based on lead acid and have not been updated, is the rationale i usually attribute

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,018

i see, just to help clarify,No, what I've was lifepo4 builds!

the idea in my head was that, some designs that are labeled for lifepo4 may have been partially "recycled" from lead acid designs in some cases

regarding fuses, lead acid batteries generally have much higher internal resistance as compared to equivalent energy capacity lifepo4

higher internal resistance means a "weaker" fuse ie lower AIC (Ampere Interrupt Current) might have become normalized

so when someone goes to design for lifepo4, and refer to a lead acid design, it could be possible some designers reused the "old" type of fuse

for example, even victron diagrams for lifepo4 specify fuses that some may consider insufficiently able to completely interrupt given lifepo4 lower internal resistance

?apologies if this is annoyingly redundant

Similar threads

- Replies

- 4

- Views

- 269

- Replies

- 22

- Views

- 2K