You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NE Solar 370W solar panel review

- Thread starter AntronX

- Start date

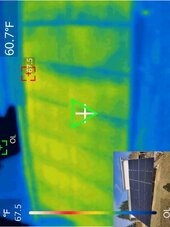

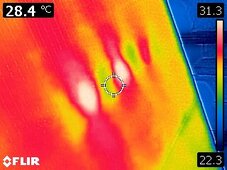

You would have to look behind the panel because thick glass will spread the heat and obscure the hot spot. EVA film is a lot thinner and would transmit a sharper thermal image. I also have a FLIR cam and will test this on a sunny day.

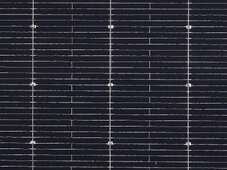

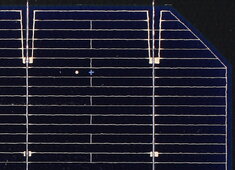

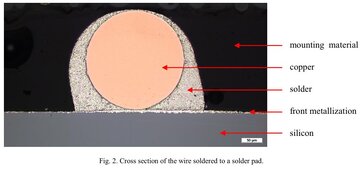

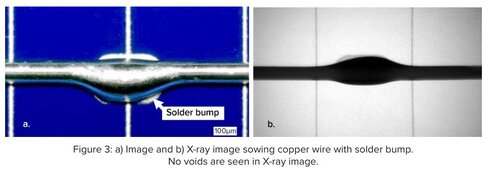

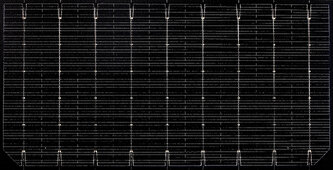

There are other joints that do have visible solder around the wire on those pads that does look like a fillet and some look like balls. The concern is there are so many completely dry pads on every panel and on almost every cell. I am looking for macro lens for my DSLR cam to show it better.Could it be the amount of solder on joints of these NE panels is correct as shown?

Last edited:

42OhmsPA

What's in a title?

PCB soldering of components is supposed to have a fillet, rather than a ball or convex shape.

Could it be the amount of solder on joints of these NE panels is correct as shown?

You know a lot more than me on that subject.

I just know they perform. My only complaint is I wish the leads were long enough to skip wire. (It might be possible flipping panel around)

MPPT 1 7S2P in the attached is a sunny day recently.

Attachments

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,809

SPC not applied or process not adjusted? (solder paste thickness, etc.)

Nah. SEM. 5dx.

I need a microscope lol.

Nah. SEM. 5dx.

ruralsolar

New Member

Total digression but...what thermal camera do you have? I had FLIR for my phone that one day decided to not power on anymore and I can't decide on what one to get next.I'll check them closer whenever the next sunny day is... I didn't see any hotspots when I checked them a few weeks ago.

42OhmsPA

What's in a title?

I'm using the Uni-T. Based off feedback here and the minimal permissions the app requests I am happy.Total digression but...what thermal camera do you have? I had FLIR for my phone that one day decided to not power on anymore and I can't decide on what one to get next.

I use a phone FLIR at work, I'd say the FLIR resolution is a a little better but I like the Uni-T more.

Just found this amazing item on AliExpress. Check it out! $109.00 50%OFF | UNI-T Thermal Camera UTi120 Mobile Phone Thermal Imager for Phone for Android IOS Type-C UTi260M Infrared Thermal Imager

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 20,809

We go through a lot of Lightning cables, buy them 5 at a time.

Not so bad when they cost around $6 each (and I'm glad it isn't the mating connector in iPhone that wears out), but do docked devices like IR camera for phone stop working just due to connector wearing out?

Not so bad when they cost around $6 each (and I'm glad it isn't the mating connector in iPhone that wears out), but do docked devices like IR camera for phone stop working just due to connector wearing out?

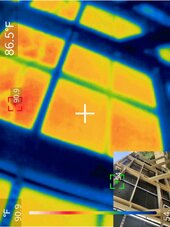

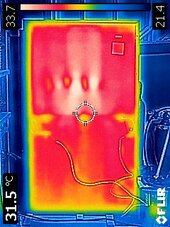

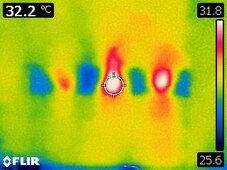

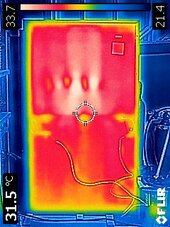

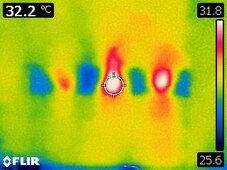

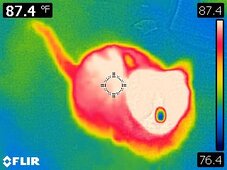

I applied 42V 10A to second panel that was scratched but not shattered to look for hot spots from poorly soldered cell wire interconnects. Discovered 3 hot spots across 4 cells that were hit by the forklift through first shattered panel. No hot spots or anomalies anywhere else.

The setup:

.

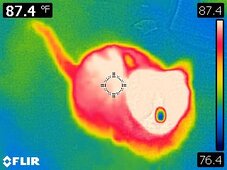

My supervisor says hi.

The setup:

.

My supervisor says hi.

Last edited:

Last edited:

I split up the original thread as requested by OP. It's in "Solar Equipment Vendor Review Corner" and renamed, the original one is in "Show and Tell".

I appreciate your attention to detail. Page prior had me concerned. This follow up dropped the blood pressureI took a closer image of the cell and it looks like some of those dry pads are actually soldered. There is so little solder that it's hard to see by naked eye. I need a microscope lol.

View attachment 188157 View attachment 188162

Side note

I’m a bit bummed in hindsight at our photo upload size discussion a few weeks back as I was simply fighting for the largest file possible hoping you wouldn’t catch on, but between your typical analysis and your photography hobby, as well as seemingly computer saviness you were 3 steps ahead. Well done ?

Well.. I am still not sure about this. The research I am reading on MBB wire stringing suggest that poor solder bump formation would accelerate cell interconnect failure from solder micro cracks caused by temperature cycling fatigue. I am still very concerned that these panels will begin failing few years into service. But at least they will pay for themselves in 9 months so that's how long they have to last for me to get my money's worth. Next time I will definitely pay extra for guaranteed quality panels.I appreciate your attention to detail. Page prior had me concerned. This follow up dropped the blood pressure

Thanks I appreciate it. I noticed that some images took long time to load and some of them were 10 Mbyte each. That also wasted a ton of storage space on this server which adds up to higher hosting expense. I would like to help keep this forum free of ads and fee of charge and making it data usage efficient is one way to achieve that. I think most users here don't really need 15 Mpixel images of various wires and other mundane stuff. For special cases it's possible to post links to google cloud or external image hosting.I’m a bit bummed in hindsight at our photo upload size discussion a few weeks back as I was simply fighting for the largest file possible hoping you wouldn’t catch on, but between your typical analysis and your photography hobby, as well as seemingly computer saviness you were 3 steps ahead. Well done ?

Now that you've had them a while, would you recommend?Worst cell I found so far. 32 of 45 solder pads (71%) are missing solder bumps. Also testing maximum image size the forum will accept without resizing. Looks like 1920 pix wide is the max.View attachment 188659

Thinking of ordering 10.

Similar threads

- Replies

- 2

- Views

- 128