There are two primary issues of not limiting inverter capacitor initial charging current.

Subjecting breaker contacts to large surge current will pit the contacts in breaker increasing breaker series resistance the more times it is done.

With lithium-ion batteries, the large surge current can trip the BMS short circuit current protection.

Usually, there is not damage to filter capacitors due to their series ESR resistance.

How large can surge current be? That depends on total path resistance. For lead-acid batteries their internal resistance greatly limits the maximum surge current, not so for Li-Ion batteries. 1000 to 3000 amps is typical.

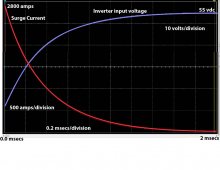

A HF 5kW 48v All-in-One inverter typically has four 4,700uF capacitors with 16 milliohms ESR each in parallel on battery input. With 14 milliohms total battery path resistance and with 55v battery, the peak current is about 2800 amps. It takes about 2 millisecs to exponentially decay to steady state.

There are inverters, like Xantrex XW series, and most LF inverters that have greater battery line input capacitors' values. Usually, the peak current is limited by battery path resistance and just the decay time is longer.

The 'at nauseum' attention given to this topic is way over discussed. Just a 0.5 to 2 ohm power resistor placed across breaker cable terminal lugs a fraction of a second before throwing breaker on is sufficient. Last time I removed battery power from my inverters was 17 years ago.

Well, I connected it to the battery three times, when I first installed it, when I changed batteries and when I moved house.

I did not "see" any surges, but then maybe I simply didn't notice. There were certainly no arcs though.

-

If capacitors are already charged, it can take hours to a couple of days to bleed the charge off.