History of critical improvements in the project system some were accidental and others were literally the only way to make it run stable.

Apparently the earth ground being used as a 60Hz grid power ground and netural makes for a 60 cycle hum that strongly effects the field effect transistors (Earth ground Bias) MOSFETs and cause problems and issues in timing. Shorts in opposing FETs and general instability in operation is the results, have encountered this with several brands of off the shelf inverters as well, most that try a DIY system with off the shelf equipment and smoke the FETs don't have a clue why it failed.

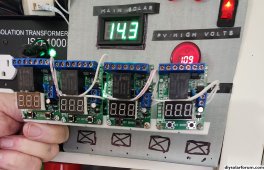

The combination of ISO transformers and the better 40N65 MOSFETs allows for extremely stable power production, you will be amazed with the stable operations, for example the moment the grid powered diode bridge was moved from the inverter case to the bottom of the secondary ISO transformer the system output more than doubled in amp flow.

The next big improvement came from bypassed input resistors on the power board, board is designed for 380VDC input and with the our direct drive 180VDC input the 40N65 FETs can more than handle the the additional output amps. Also turning the potentiometer full clockwise sets the CPU for Maximum power after the soft start.

Also another bias has been noted when blending equal amounts of solar and grid based DC, the instructions refer to it as syncing from two sorces and refer to it as hot/cold cathode problem, The bias causes the production of static charges like a Marx generator and will destroy the diode bridge and FETs.

The static forms arcs that provide shorts across the silicone electronics till damage is done, the ISO transformers prevent all of this from happening.

All though the ISO transformers are a bit pricey have yet to find a low cost alternative that actually provide the same rock solid operation and safety!

Have been in commercial electronics for a long long time, the stable output and pure sine power of this tiny power board is simply amazing, You need one or more.

The hybrid grid support and voltage boosted solar system makes for more PV power in full sun and stable operations accross a wide range of solar sky conditions and loads.

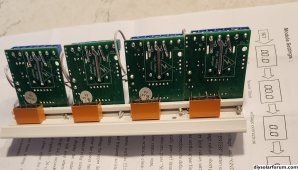

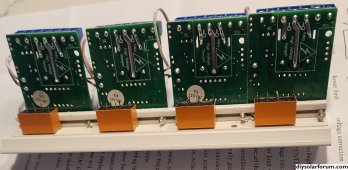

Beefing up the power board DC traces to the FETs and additional pure copper wires on the AC output traces make a difference you can see on a quartz tube heater. Maximum stability comes from just 4 of the 40N65 MOSFETs. 8 FETs can do more power but keeping 8 FETs in perfect sync is tricky, out of sync FETs will short out in opposing pairs.

More in a few days.

Best wishes