You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Newbie with a container needing advice

- Thread starter TimmehTim

- Start date

I know it's it's lot of 10 guage, but I have two 500 foot spool of it already and I have 12 feet of 4awg. I may be running an extra 7 feet of 10awg Is all.The combiner box is normally right next to the panels. This way you only run 1 pair of long wires to the SCC instead of a long pair for each parallel string.

The busman style breakers have terminals listed "BAT" and "AUX". I assume I should have the BAT connected to the batteries and the AUX connected to the SCC. But I also realize the power source I'm trying to protect would be the SCC so maybe I should have the BAT side connected to the SCC and the AUX side connected to the batteries. ...Did I mention I'm dyslexic? ?

OK. The idea is to keep voltage drop to a minimum. A few extra feet should make little difference. How long will each wire be from the panels to the combiner box?I know it's it's lot of 10 guage, but I have two 500 foot spool of it already and I have 12 feet of 4awg. I may be running an extra 7 feet of 10awg Is all.

The breaker should be labeled less confusingly. For the breaker between the SCC (the power source) and the battery (the power load in this case) you should actually connect the "BAT" end to the SCC and the "AUX" end to the battery. So your second idea is the correct one.The busman style breakers have terminals listed "BAT" and "AUX". I assume I should have the BAT connected to the batteries and the AUX connected to the SCC. But I also realize the power source I'm trying to protect would be the SCC so maybe I should have the BAT side connected to the SCC and the AUX side connected to the batteries.

I have the same Bussman brand 285 breaker for my SCC. I confirmed the direction with the reputable dealer I purchased it from. But they did say they have never seen an issue with the breaker being wired either way.

The furthest panels will have 25 feet of cable connected after the factory harnesses. Each panel gets closer by 3 feet until the last panel is 3 feet away.OK. The idea is to keep voltage drop to a minimum. A few extra feet should make little difference. How long will each wire be from the panels to the combiner box?

Cool. I got something right! Thanks for confirming.The breaker should be labeled less confusingly. For the breaker between the SCC (the power source) and the battery (the power load in this case) you should actually connect the "BAT" end to the SCC and the "AUX" end to the battery. So your second idea is the correct one.

I have the same Bussman brand 285 breaker for my SCC. I confirmed the direction with the reputable dealer I purchased it from. But they did say they have never seen an issue with the breaker being wired either way.

Now I've made some updates to wire sizing...

From the panels to the combiner box I have 10awg (max 25 feet).

From the combiner box to the SCCs I am running 4awg.

From the SCCs to the bus bars I'm running 4awg with Busman 75amp breakers on the positive lines.

From the bus bars to the batteries I'm running 4/0 with a 350amp ANL fuse and a DC disconnect on the positive.

The batteries will all be connected with 4/0.

The bus bars will be connected to the Inverter with 4/0 with a DC disconnect on the positive.

The Inverter will be connected to the Breaker Box with 10awg wire directly from the Inverters terminal block.

And the Breaker Box will supply appliances with 12/2.

That sound proper?

Next question:

Can I run 6 panels on one SCC

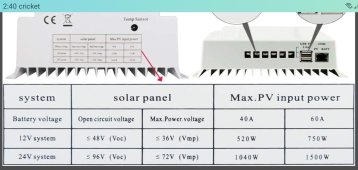

Solar Panel -

Pmax: 290W

Voc: 44.4V

Isc: 8.64A

Ran in parallel -

Voc: 44.4V

Isc: 51.84A

Pmax: 1740W

To the SCC -

Voc: 96v

Vmp: 72v

1040w @ 40A

1500w @ 60A

Can I run 6 panels on one SCC

Solar Panel -

Pmax: 290W

Voc: 44.4V

Isc: 8.64A

Ran in parallel -

Voc: 44.4V

Isc: 51.84A

Pmax: 1740W

To the SCC -

Voc: 96v

Vmp: 72v

1040w @ 40A

1500w @ 60A

Attachments

You will be a little over paneled but 6 panels would work but only in 6P. The Voc is too high to put any in series.Can I run 6 panels on one SCC

You need to adjust your wiring from the combiner box to the SCC to handle 52A at 44V. The 4AWG might still be OK depending on the distance from the combiner to the SCC.

Im only about 18 inches between the combiner box and the SCC. Can't 4awg handle 60-70 amps?You will be a little over paneled but 6 panels would work but only in 6P. The Voc is too high to put any in series.

You need to adjust your wiring from the combiner box to the SCC to handle 52A at 44V. The 4AWG might still be OK depending on the distance from the combiner to the SCC.

4AWG is good up to 100A if the distance is short enough.

Given how short the distance is from the combiner box to the SCC, you can use 6AWG without any issue. Of course 4AWG works too assuming the the SCC can accept 4AWG. My original recommendation for 4AWG was on the assumption that the combiner box would be close to the panels and far from the SCC. But you have the opposite.

Given how short the distance is from the combiner box to the SCC, you can use 6AWG without any issue. Of course 4AWG works too assuming the the SCC can accept 4AWG. My original recommendation for 4AWG was on the assumption that the combiner box would be close to the panels and far from the SCC. But you have the opposite.

With the distance between the Combiners and the SCCs and the distance between the SCCs and the Bus Bars all being less than 2 feet a piece, could I use 6awg on those connections? 6awg would fit much better in the SCC. 4awg is SUPER tight.4AWG is good up to 100A if the distance is short enough.

Given how short the distance is from the combiner box to the SCC, you can use 6AWG without any issue. Of course 4AWG works too assuming the the SCC can accept 4AWG. My original recommendation for 4AWG was on the assumption that the combiner box would be close to the panels and far from the SCC. But you have the opposite.

The wire needs from the combiner box to the SCC are completely independent of the wire needs from the SCC to the bus bars.

Based on the 52A from panels in 6P you can use 6AWG from the combiner box to the SCC due to the short length.

Based on the fact that your SCC has a max charge current of 60A then you can use 6AWG from the SCC to the bus bars. I think the original recommendation of 4AWG (actually 2AWG) was due to the original plan having a 100A SCC, not a 60A.

So it turns out that both can use 6AWG but that's just a coincidence.

Based on the 52A from panels in 6P you can use 6AWG from the combiner box to the SCC due to the short length.

Based on the fact that your SCC has a max charge current of 60A then you can use 6AWG from the SCC to the bus bars. I think the original recommendation of 4AWG (actually 2AWG) was due to the original plan having a 100A SCC, not a 60A.

So it turns out that both can use 6AWG but that's just a coincidence.

Because of you, I might just survive this.The wire needs from the combiner box to the SCC are completely independent of the wire needs from the SCC to the bus bars.

Based on the 52A from panels in 6P you can use 6AWG from the combiner box to the SCC due to the short length.

Based on the fact that your SCC has a max charge current of 60A then you can use 6AWG from the SCC to the bus bars. I think the original recommendation of 4AWG (actually 2AWG) was due to the original plan having a 100A SCC, not a 60A.

So it turns out that both can use 6AWG but that's just a coincidence.

As a side note to my tongue-in-cheek previous comment. While I am attempting to offer correct and constructive feedback, please make it your own responsibility to understand how and why those recommendations are being made and verify that they are in fact correct and meet your needs.

Last edited:

I'm still waiting on a battery, but I thought I'd mock up the wiring plan I had in mind and get opinions on it.

These batteries are 12v 200ah.

Would the attached images be the correct way to wire them to obtain 24v 400ah? And is there any other way to configure them for a 24v system that would give it more capa ity or better efficiency (other than switching to a 48v system ?).

Thank you.

These batteries are 12v 200ah.

Would the attached images be the correct way to wire them to obtain 24v 400ah? And is there any other way to configure them for a 24v system that would give it more capa ity or better efficiency (other than switching to a 48v system ?).

Thank you.

Attachments

IM STILL ALIVE!

Well, I (we) did it. With the help for you fine people I have enjoyed my first night completely off grid and with no generator.

I've only hooked up one array or 6 panels all.goong through one of the SCCs. I was down to 50% battery this morning, down from 64% when I connected (I had precharged all the batteries to 100% so I'm not sure I understand how they could be down to 64% upon connection). But even with the mini split pumping heat, the refrigerator pumping cold and a little nuking of left overs at the microwave, it was able to climb to 100% in a matter of hours.

So far so good!

Well, I (we) did it. With the help for you fine people I have enjoyed my first night completely off grid and with no generator.

I've only hooked up one array or 6 panels all.goong through one of the SCCs. I was down to 50% battery this morning, down from 64% when I connected (I had precharged all the batteries to 100% so I'm not sure I understand how they could be down to 64% upon connection). But even with the mini split pumping heat, the refrigerator pumping cold and a little nuking of left overs at the microwave, it was able to climb to 100% in a matter of hours.

So far so good!

Attachments

Similar threads

- Replies

- 13

- Views

- 597

- Replies

- 8

- Views

- 214

- Replies

- 10

- Views

- 842

- Replies

- 5

- Views

- 365