It's sort of a "dream come true" scenario this. My first solar adventure charged my phone 9 out of 12 months of the year. Back then I had ideals of running a 24/7 server on solar and realising how far away my little 50W 12V setup was from that.

Fast forward 5 years and about £2000 and I have this now. Running the entire office! Battery storage, transfer switch the works.

It suddenly feels less "DIY" and less "jury rigged" and more professional. Mostly thanks to me investing into the Victron Multiplus which has made the whole off-grid with grid fall back seamless!

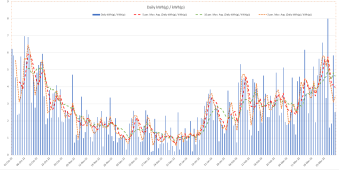

The graph above shows two fairly poor days weather wise, which followed an even worse day. Yet the majority of power came from the inverter.

The transitions need more tuning, but currently under 25.50V for 2 minutes switches over to grid. Should it ever occur the battery charger is enabled for a short boost at 25.5V and float at 25.00V. When the voltage rises above 26.50V again the inverter switches back to ON and disconnects the AC-In entirely.

This gives the battery a small head start in the morning to prevent ping-pong. Seems to be working so far.

A few things are not on this circuit, the main server (35-60W 24/7) and the gaming PC 500W for an hour or two at a time. For those I need to wait for the next upgrade (financing). Going from 330W panels to 1kW panels and I have my eyes on a set of 8 280Ah cells taking storage up to about 8kWh. Then I should be able to run the full office 24/7 with the gaming PC potentially triggering a grid fall back if the total exceeds the 400W sustained from the inverter.... and I can always chain or parallel another multi in there to take that up to 800W say.

Fast forward 5 years and about £2000 and I have this now. Running the entire office! Battery storage, transfer switch the works.

It suddenly feels less "DIY" and less "jury rigged" and more professional. Mostly thanks to me investing into the Victron Multiplus which has made the whole off-grid with grid fall back seamless!

The graph above shows two fairly poor days weather wise, which followed an even worse day. Yet the majority of power came from the inverter.

The transitions need more tuning, but currently under 25.50V for 2 minutes switches over to grid. Should it ever occur the battery charger is enabled for a short boost at 25.5V and float at 25.00V. When the voltage rises above 26.50V again the inverter switches back to ON and disconnects the AC-In entirely.

This gives the battery a small head start in the morning to prevent ping-pong. Seems to be working so far.

A few things are not on this circuit, the main server (35-60W 24/7) and the gaming PC 500W for an hour or two at a time. For those I need to wait for the next upgrade (financing). Going from 330W panels to 1kW panels and I have my eyes on a set of 8 280Ah cells taking storage up to about 8kWh. Then I should be able to run the full office 24/7 with the gaming PC potentially triggering a grid fall back if the total exceeds the 400W sustained from the inverter.... and I can always chain or parallel another multi in there to take that up to 800W say.