Hey, long time stalker of the forum for information gathering. I am currently considering going off grid and would like some general feedback on my planed setup based on stats/circumstance.

I do have one specific question as regard long distance cable to my house that I have been unable solve based on research…

So I have an acreage (approx. 10 acres), myself and my wife, 2000 sq ft home. In terms of high usage items we have X2 fridge freezers, electric stove, electric hot water heater, Network Acess Storage running 24/7 and a hot tub. All our heating is gas. EDIT + 240v water well pump feeding the house.

I am living in Alberta Canada so things can get cold and less light during the winter months.

I broke down my yearly actual readings from our electric company:-

Yearly:- 13569KWh

Monthly:-1130KWh or 14125KWh (25% buffer added)

Daily:-37.175

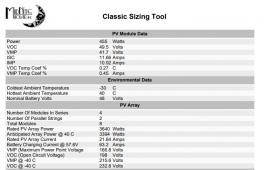

I found a formula:- Panel number = kWh usage / production ratio specific to my area / wattage

1412/1.09/550 = 28 panels

Looking at a 48v battery bank calculation (via various websites) I’m estimating 45KWh’s at minimum (I would like more but the cost is crazy)

Due to cost I am looking at pairing 3 lots of 16 3.2v 280ah via the recommended Alibaba sellers on this forum.

My basic equipment list is:

X2 LV6548 in split phase

X4 2P4S Longi 455W panels

A wooden DIY ground mount

3 lots of 16 3.2v 280ah with an appropriate BMS

In terms of VOC and cold climate I found the above array formulation seemed ok for the 250v limit of the inverter (via Midnight solar tool)

VMP @ -40 C 215.6 Volts

VOC @ -40 C 232.8 Volts

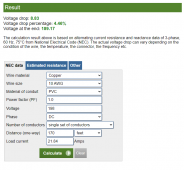

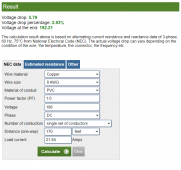

My difficulty is that the available land for the solar panels is 170ft from my main electrical panel. The mech room is to the rear of the house meaning running cabling through the hall ceiling.

To make matters more complicated I have no space in my mech room for all of the equipment. I would like to build a shed (well insulated) where the panels are mounted to hold everything and then run the 240 AC cable (L1 L2 and N) to the mech room to hookup to my electrical panel.

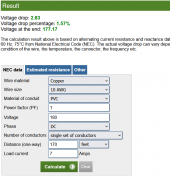

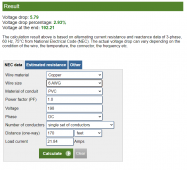

Based on research a higher voltage will have less voltage drop? What I can’t figure out is what gauge wire will be needed for the feed. I have a 200amp main panel.

Any thoughts, advice or highlighting errors in the above would be appreciated. The feed to the house is my current sticking point…

Thanks!

I do have one specific question as regard long distance cable to my house that I have been unable solve based on research…

So I have an acreage (approx. 10 acres), myself and my wife, 2000 sq ft home. In terms of high usage items we have X2 fridge freezers, electric stove, electric hot water heater, Network Acess Storage running 24/7 and a hot tub. All our heating is gas. EDIT + 240v water well pump feeding the house.

I am living in Alberta Canada so things can get cold and less light during the winter months.

I broke down my yearly actual readings from our electric company:-

Yearly:- 13569KWh

Monthly:-1130KWh or 14125KWh (25% buffer added)

Daily:-37.175

I found a formula:- Panel number = kWh usage / production ratio specific to my area / wattage

1412/1.09/550 = 28 panels

Looking at a 48v battery bank calculation (via various websites) I’m estimating 45KWh’s at minimum (I would like more but the cost is crazy)

Due to cost I am looking at pairing 3 lots of 16 3.2v 280ah via the recommended Alibaba sellers on this forum.

My basic equipment list is:

X2 LV6548 in split phase

X4 2P4S Longi 455W panels

A wooden DIY ground mount

3 lots of 16 3.2v 280ah with an appropriate BMS

In terms of VOC and cold climate I found the above array formulation seemed ok for the 250v limit of the inverter (via Midnight solar tool)

VMP @ -40 C 215.6 Volts

VOC @ -40 C 232.8 Volts

My difficulty is that the available land for the solar panels is 170ft from my main electrical panel. The mech room is to the rear of the house meaning running cabling through the hall ceiling.

To make matters more complicated I have no space in my mech room for all of the equipment. I would like to build a shed (well insulated) where the panels are mounted to hold everything and then run the 240 AC cable (L1 L2 and N) to the mech room to hookup to my electrical panel.

Based on research a higher voltage will have less voltage drop? What I can’t figure out is what gauge wire will be needed for the feed. I have a 200amp main panel.

Any thoughts, advice or highlighting errors in the above would be appreciated. The feed to the house is my current sticking point…

Thanks!

Last edited: