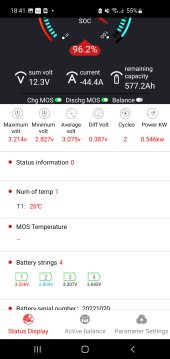

When I discharge my 600ah pack one cell is discharging faster than others, dropping to 2.8v when I put a load on while the others sit at 3.2 or there abouts. It's not a capacity problem as I have just capacity tested each cell after top balancing them and paired the weakest with the strongest and so on. I didn't top balance the pack when I connected them together as it would take years to charge the whole pack at 3.65v but is this problem being caused because the pack hasn't been top balanced properly or is it something else?

When I discharge my 600ah pack one cell is discharging faster than others, dropping to 2.8v when I put a load on while the others sit at 3.2 or there abouts. It's not a capacity problem as I have just capacity tested each cell after top balancing them and paired the weakest with the strongest and so on. I didn't top balance the pack when I connected them together as it would take years to charge the whole pack at 3.65v but is this problem being caused because the pack hasn't been top balanced properly or is it something else?