1) After reading both the solar charge controller and inverter manuals I'm unsure how to ground this system. See page 5

My approach was that I grounded those components that explicitly require grounding. The solar charge controllers, inverter and AC-DC converter. I did not run a lead from my negative bus bar to the ground bus bar. There is some discussion on this and I went with the "required" grounds.

The positive ground on the Renogy I have no idea on. Is that component made by Lucas (inside joke for British car fans)?

2) I'm unsure if it matters when connecting the batteries to the system which you connect first, positive or negative. My husband says it doesn't, but he also told be that we could connect this up without reading the manuals. LoL! He's a math man, not a handy man.

I always connect negative last and disconnect negative first.

3) Wire sizes. I've used the online wire calculators and load drop calculators and "think" I have these correct. In some areas you will notice that I put a wire gauge range in but did not choose one yet. That is because I am still unsure which size is best in that spot for my system design. Suggestions are welcomed.

The couple that I saw looked OK. I ran 2/0 from my common bus bar to within about 3' of the trailer's main AC and DC distribution panel. Then from there I ran 6 gauge for the final 3'. My distribution panel has connections for two wires, not much larger than 6 gauge (the 2/0 would NEVER fit). I ran out of 6 gauge so I ran only one wire for each pos/neg leg. Once I resupply on 6 gauge I'll do the second wire. It's overkill as the OEM install at the factory used one wire.

8 gauge PV wire isn't all that common. 10 gauge is more common and that's what I used. If you use standard MC4 connectors, they may not work with 8 gauge PV wire. Your mileage may vary.

My approach was to put the biggest cable in that the component allowed. When a component called for or allowed something smaller and I had that cable I went with that. I limited my initial install to 10 gauge PV, 6 gauge welding, 2/0 gauge welding. I subsequently added 1 gauge because I didn't like how the existing inverter wires ended up.

I used a 250 amp Class T fuse downstream of the battery. This was based on recommendations found here. It's very expensive, but I wanted the best protection at that location. Your battery cable sizes will depend on distance, voltage and how many amps you think will go down the cable. The battery Ah isn't what dictates the cable size. I went with 2/0 based on distance, voltage and amps. My system is very compact, cable runs are short.

I don't see a disconnect switch between the battery and the fuse. Highly recommended.

A set of common bus bars makes wiring a lot easier. You can put only so many ring terminals/lugs on a post. I see the bus bars on page 1 but not page 2.

You can directly wire the batteries together, but you don't have to. 4/0 is likely overkill. I chose to keep the batteries distinct. They "connect" only at the fuse and the shunt.

I did not use any wire nuts in my system. Everything uses crimped on ring terminal or crimped on butt connectors. I'm a little anal about it though.

4) We have another location option for the equipment that is slightly larger and closer to where the wires enter the roof. It is the other dinette bench that is just behind the RV axels. It's larger because it doesn't have a wheel well or any other factory installed wires & equipment in it. I'd like to use it but don't want to put too much weight behind the wheels. Page 4 has more info on this. Thoughts?

My experience is that the more room you have to work with, the easier the install. Big cables bend only so much. A large area allows for a cleaner install at the expense of more cable. A cramped location can result in dropped tools.

It's good that you're considering the impact on weight. You're probably removing the batteries from the tongue so that right there is a big change. Do you know what your tongue weight is now? 10% to 15% is the target for good handling. Anything less than 10% is a problem. Maybe you can travel with a larger amount of water in the fresh water tank? Add a toolbox on the tongue?

I'm handy and like to troubleshoot stuff and DIY but this kind of project is new to me. Our goal is to build the largest and most efficient solar system that we can afford. We've gone over budget already buying stuff that others told us to buy without first understanding what we were doing. That was a big mistake, 20/20 hindsight. We've returned things we could return. At this point, the larger components we have we own and need to make them work if possible. Thank you all for your insight, direction, and assistance.

I blew my budget by almost 30%. A good amount of that was tools so I'm less concerned about that part of it. I'll be using those tools on the "next" RV, as well as other projects I'm sure. I bought a few things by mistake and had to buy the right things. The biggest logistics issues I had were cable lugs (ring terminals) and heat shrink tubing. Either I didn't have enough lugs for the stud size or I didn't have enough lugs for the cable size. Heat shrink tubing was on backorder. I did the install without it. Now that I have it, I need to take things apart to retrofit the heat shrink tubing on.

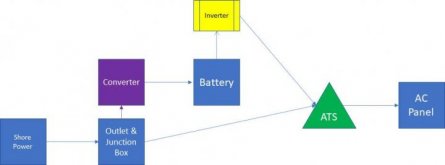

The converter is going to be a problem. If you were to buy an inverter/charger combo, that would solve the problem in a single component. If you buy the Windy Nation inverter then you'll need the separate converter and the transfer switch. Some inverter/charger units eliminate the need for the transfer switch, but that's an expensive option. If you tap power for the converter before the shore power hits the transfer switch then that solves the problem of having the converter on when it shouldn't be.