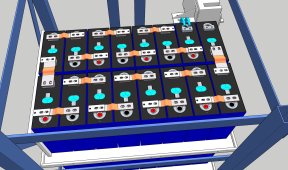

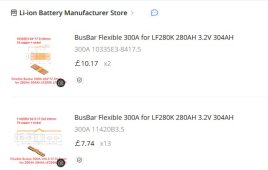

If you have built a pack using the new EVE LF280K cells featuring the new, dual stud, terminals, please show me some of your photos and are you using the standard bus bars that came with the cells or one of the flexible bar options from aliexpress?

I just pre-ordered 8 cells from the next batch arriving at 18650batterystore.com around Oct. 25th to build my first ever lifepo4 pack. I don't recall seeing any pics or videos of these new cells assembled yet so I'm curious how they are working out.

I just pre-ordered 8 cells from the next batch arriving at 18650batterystore.com around Oct. 25th to build my first ever lifepo4 pack. I don't recall seeing any pics or videos of these new cells assembled yet so I'm curious how they are working out.

Last edited: