douglasheld

New Member

Hello all, I have a simple setup with a single 120W monocrystalline panel, a charge controller and a 130Ah lead-acid battery. There's also an inverter which I only turn on as needed, e.g. to run a power tool.

After working adequately for 5 months or so, I found that my PV output is displayed 0.1V and 0W on the charge controller. This started yesterday and it's been two completely overcast days.

I disconnected the PV cables, re-cut and re-crimped them and measured with my voltmeter. 0V, no continuity and no current (0µA). For good measure, I went up to the roof, disconnected two MC4 connectors and tested there as well. It's 0V. Physically, the panel looks fine.

I have been fiddling with the system the past few days however. And what I assumed is that I must have fried this panel by accidentally connecting the PV outputs to 12V. But in a search of the forum, to my surprise this doesn't seem to be a frequently encountered problem by beginners.

The only other thing I can think of is that I could have given it a static shock, as I touched the frame yesterday. I didn't feel any shock.

I will tell you all the things I have been messing with, in case anybody has an idea:

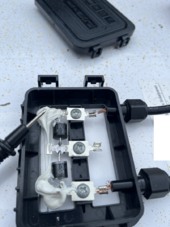

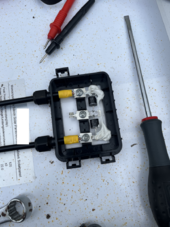

So, my question: what plausibly could be wrong with my panel? I've written to the manufacturer to ask if it's got a fuse inside. I do not know if this panel has a bypass diode - I've asked the manufacturer about that as well.

After working adequately for 5 months or so, I found that my PV output is displayed 0.1V and 0W on the charge controller. This started yesterday and it's been two completely overcast days.

I disconnected the PV cables, re-cut and re-crimped them and measured with my voltmeter. 0V, no continuity and no current (0µA). For good measure, I went up to the roof, disconnected two MC4 connectors and tested there as well. It's 0V. Physically, the panel looks fine.

I have been fiddling with the system the past few days however. And what I assumed is that I must have fried this panel by accidentally connecting the PV outputs to 12V. But in a search of the forum, to my surprise this doesn't seem to be a frequently encountered problem by beginners.

The only other thing I can think of is that I could have given it a static shock, as I touched the frame yesterday. I didn't feel any shock.

I will tell you all the things I have been messing with, in case anybody has an idea:

- swapped a 20A PWM charge controller for a Victron MPPT 15A charge controller. I swapped these back and forth a few times.

- for a day had both charge controllers connected to the battery, but only one charger controller connected to PV

- removed and reseated the battery terminal connections

- started installing an equipment bonding system. I have bonded an inverter to the PV frame up on the roof.

- I'm also in the process of inventorying all my cable specifications, as I need to add fuses to the system. So, I've been handling all the cables to photograph the cable markings and anything I can see on the crimped ring lugs.

So, my question: what plausibly could be wrong with my panel? I've written to the manufacturer to ask if it's got a fuse inside. I do not know if this panel has a bypass diode - I've asked the manufacturer about that as well.

Last edited: