You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Recommendations on Ground Source Heat Pump with soft start?

- Thread starter AlaskanNoob

- Start date

I respectfully disagree that a specific fluid velocity is needed for heat transfer, or that an oversized ground source loop is a probem, except for the circulation pump if the static head gets too high so that volume falls off dramatically. I realize that in some systems it can appear so, but the reality is that it is not. The BTU heat transfer from the pipe to the soil is not affected by the velocity of the water. As the water flow slows, the return water temperature may be have a closer approach temperature to the soil temp, but BTU's are not improved, since water volume is less. It is a matter of physics and conservation of energy. It is a very popular misconception among skilled plumbers, HVAC techs, and some very skilled auto mechanics.

A larger loop will let your approach to the soil temperature be smaller and is not problematic. In Alaskanoob's case, his loop will return will be colder than 32F. What I forgot to consider before is Alaskanoob will always be at least a few degrees below 32F back from his ground loop, and might be getting only 20F (or worse) water back from the loop by January, as the soil around the pipes gets chilled. A larger loop will help that, not hurt, but I suggest he look again at the heat pump performance data for 22F return water temperature. Some data from similar GSHP systems in the area sure would sure help.. The paper I referenced above would help an engineer do the ground loop design since they did measure soil thermal transfer in 32F soil.

Alaskanoob, do you have performance data for 22F incoming water? That may greatly affect the heat output. Sorry I forgot that you will won't see 32F or better at 9-10 foot until late summer or fall. My mistake.

Another paper suggests that modest depth increases will not help in your near frozen soils.

A larger loop will let your approach to the soil temperature be smaller and is not problematic. In Alaskanoob's case, his loop will return will be colder than 32F. What I forgot to consider before is Alaskanoob will always be at least a few degrees below 32F back from his ground loop, and might be getting only 20F (or worse) water back from the loop by January, as the soil around the pipes gets chilled. A larger loop will help that, not hurt, but I suggest he look again at the heat pump performance data for 22F return water temperature. Some data from similar GSHP systems in the area sure would sure help.. The paper I referenced above would help an engineer do the ground loop design since they did measure soil thermal transfer in 32F soil.

Alaskanoob, do you have performance data for 22F incoming water? That may greatly affect the heat output. Sorry I forgot that you will won't see 32F or better at 9-10 foot until late summer or fall. My mistake.

Another paper suggests that modest depth increases will not help in your near frozen soils.

S Davis

Solar Enthusiast

- Joined

- Sep 25, 2021

- Messages

- 598

I can tell you are not trained in geothermal, flow rates have everything to do with the heat transfer of a geothermal system, you need turbulent flow for good transfer.

Also more tube will not do anything after a certain point, once you have reached the capacity of the ground it doesn’t help to add more tube you can’t absorb more heat than is there, going over a 48” pitch slinky usually doesn’t gain much unless you are in very wet soil. You need more ditch length and then size the pumps for the extra head pressure.

I run into systems all the time that the contractor or home owner decided installing more tubing was better, most of the time it doesn’t mean more heat just a bigger pump station and less efficiency. You need more ditch, tubing and usually a larger pump station for added capacity.

To the OP get several quotes and get references from past jobs, design is critical on these systems. Take advice over the internet with a grain of salt. I have seen a lot of messed up jobs in my 32 years in HVAC, I have been a HVAC contractor for 20 years and design these systems for a living. I am also a IGSHPA certified designer/installer.

Also more tube will not do anything after a certain point, once you have reached the capacity of the ground it doesn’t help to add more tube you can’t absorb more heat than is there, going over a 48” pitch slinky usually doesn’t gain much unless you are in very wet soil. You need more ditch length and then size the pumps for the extra head pressure.

I run into systems all the time that the contractor or home owner decided installing more tubing was better, most of the time it doesn’t mean more heat just a bigger pump station and less efficiency. You need more ditch, tubing and usually a larger pump station for added capacity.

To the OP get several quotes and get references from past jobs, design is critical on these systems. Take advice over the internet with a grain of salt. I have seen a lot of messed up jobs in my 32 years in HVAC, I have been a HVAC contractor for 20 years and design these systems for a living. I am also a IGSHPA certified designer/installer.

I respectfully disagree that a specific fluid velocity is needed for heat transfer, or that an oversized ground source loop is a probem, except for the circulation pump if the static head gets too high so that volume falls off dramatically. I realize that in some systems it can appear so, but the reality is that it is not. The BTU heat transfer from the pipe to the soil is not affected by the velocity of the water. As the water flow slows, the return water temperature may be have a closer approach temperature to the soil temp, but BTU's are not improved, since water volume is less. It is a matter of physics and conservation of energy. It is a very popular misconception among skilled plumbers, HVAC techs, and some very skilled auto mechanics.

A larger loop will let your approach to the soil temperature be smaller and is not problematic. In Alaskanoob's case, his loop will return will be colder than 32F. What I forgot to consider before is Alaskanoob will always be at least a few degrees below 32F back from his ground loop, and might be getting only 20F (or worse) water back from the loop by January, as the soil around the pipes gets chilled. A larger loop will help that, not hurt, but I suggest he look again at the heat pump performance data for 22F return water temperature. Some data from similar GSHP systems in the area sure would sure help.. The paper I referenced above would help an engineer do the ground loop design since they did measure soil thermal transfer in 32F soil.

Alaskanoob, do you have performance data for 22F incoming water? That may greatly affect the heat output. Sorry I forgot that you will won't see 32F or better at 9-10 foot until late summer or fall. My mistake.

Another paper suggests that modest depth increases will not help in your near frozen soils.

Attachments

S Davis

Solar Enthusiast

- Joined

- Sep 25, 2021

- Messages

- 598

You can’t size the unit based on its listed output it has to be able to absorb the heat from the ground and have enough off time for the ground to recoup.Thank you for those wise words. Somebody else here in Alaska who is more familiar said that I need to see the efficiency of the pump with inlet water temps of 32F so that might be how cold it gets at 10 feet underground here. The design heat load from the calculations I've done using some software, appears to be 17K BTU for our small cabin. The unit is a two ton unit so it can put out 24K BTU. But with 32F inlet temps, the efficiency of the unit drops down. I'm still trying to figure out the chart to see how many BTU it can put out with the colder inlet temps but haven't cracked the code yet. It appears that at 30F and the compressor running full speed, it can put out 29 MBTUH. I'm not sure how that equates to BTU output of the unit though to see if it will meet the 17K BTU design heating load.

The unit might be able to out put that BTU rating at 32 degree incoming water temp but if the unit doesn’t have long enough off cycles it will continue to pull the ground temp lower until the unit fails on high head pressure.

People think it is all about the equipment but the loop field is the most important design aspect. I can’t give you advice on the size of equipment or loop field, it is really location specific. We haven’t even talked about the type of soil you have at 10’ of depth, clay, sand, rock it can make a huge difference on your heat transfer.

I'd love to see some data on this critical flow rate/ turbulence. What is the critical flow for from various sizes of tubing that might be used in residential systems, and how much does it affect perfomance? I've read it discussed in academic papers on large commercial vertical bore systems, but they concluded that pipe diameter was the dominant factor. In small tubing, I can't imagine it; there is just too small a cross section. So eagerly looking forward to leaning something new.

I certainly agree that the OP should have an engineer design this system, preferably one with experience in Alaska. It is not a situation for TLAR engineering, unless you have very good construction and perfomance data on a similar home in the same climate.

I missed the last post before this one. I agree wholeheartedly that the price for an expert design and soil analysis is critical, especially for this location. I have no idea how freezing affects soil conduction, but it may be an important issue in addition to clay vs sand and moisture level. I would not believe anyone's general assertions as to soil temperature at depth for a challenging location like this without data to support it.

I certainly agree that the OP should have an engineer design this system, preferably one with experience in Alaska. It is not a situation for TLAR engineering, unless you have very good construction and perfomance data on a similar home in the same climate.

I missed the last post before this one. I agree wholeheartedly that the price for an expert design and soil analysis is critical, especially for this location. I have no idea how freezing affects soil conduction, but it may be an important issue in addition to clay vs sand and moisture level. I would not believe anyone's general assertions as to soil temperature at depth for a challenging location like this without data to support it.

Last edited:

On the 17KBTU needed and rated 24KBTU, 2 ton unit. You have a problem, as normal the marketing style rated BTU is at a COP of 5 or higher...their highest efficiency performance, often. The info is in the manual were you got the performance data. You showed a COP Of 2.8 at 32F incoming water, so the marketing performance is roughly 2.9/5 or 58% of the rated. You only get roughly 13.9KBTU of heating, probably less since the rated BTU COP may be much higher.

Because you're off grid, you'd like to minimize power, so the ground loop will have to be sized for near continuous operation through the winter, at near your max rated capacity. If your ground source return water temperature drops much by late January, so will your COP. If you can't throw more power at it, you get won't the BTUs. Normally the electronic controller of the compressor and expansion valve will limit the hot side pressure and temperature, up to the safe operating limit of the compressor. If you don't have the extra compressor capacity available, heating will be limited.

COP is watts in/watts of heating out, which can be directly converted to BTUs.

Because you're off grid, you'd like to minimize power, so the ground loop will have to be sized for near continuous operation through the winter, at near your max rated capacity. If your ground source return water temperature drops much by late January, so will your COP. If you can't throw more power at it, you get won't the BTUs. Normally the electronic controller of the compressor and expansion valve will limit the hot side pressure and temperature, up to the safe operating limit of the compressor. If you don't have the extra compressor capacity available, heating will be limited.

COP is watts in/watts of heating out, which can be directly converted to BTUs.

Last edited:

S Davis

Solar Enthusiast

- Joined

- Sep 25, 2021

- Messages

- 598

On another note it will not do any good if you go with a piece of equipment that the people in your area are not familiar with and don’t have repair parts available for, especially in Alaska. I am in Wa state and have huge issues getting repair parts so I stock the more common ones for the units I work on.

On the subject of service and parts availability. We have had a terrible time finding competent techs who can do both the ground loop and compressor side of things. Topping that off, we have been waiting over a month for a simple expansion valve to replace our clogged one.On another note it will not do any good if you go with a piece of equipment that the people in your area are not familiar with and don’t have repair parts available for, especially in Alaska. I am in Wa state and have huge issues getting repair parts so I stock the more common ones for the units I work on.

IMO, having a competent company that stands behind their product, is paramount.

AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

I appreciate all that information. Can you tell me where you are getting you soil temp data from? Alaska is a huge state with a lot of temperature differential so you may be thinking I'm up north. From the Alaska energy folks I've talked to in Fairbanks (which is much colder than where I am) they told me to make sure the unit can handle 32F temps. They have a horizontal ground loop in Fairbanks and have done some reports on it and they indicate that the temp only nine feet down maintained about 32F during winter. Our location is much warmer in the winter and cooler in the summer. So while our winters are more mild than their winters, we don't get the recharge they get in the summer.I respectfully disagree that a specific fluid velocity is needed for heat transfer, or that an oversized ground source loop is a probem, except for the circulation pump if the static head gets too high so that volume falls off dramatically. I realize that in some systems it can appear so, but the reality is that it is not. The BTU heat transfer from the pipe to the soil is not affected by the velocity of the water. As the water flow slows, the return water temperature may be have a closer approach temperature to the soil temp, but BTU's are not improved, since water volume is less. It is a matter of physics and conservation of energy. It is a very popular misconception among skilled plumbers, HVAC techs, and some very skilled auto mechanics.

A larger loop will let your approach to the soil temperature be smaller and is not problematic. In Alaskanoob's case, his loop will return will be colder than 32F. What I forgot to consider before is Alaskanoob will always be at least a few degrees below 32F back from his ground loop, and might be getting only 20F (or worse) water back from the loop by January, as the soil around the pipes gets chilled. A larger loop will help that, not hurt, but I suggest he look again at the heat pump performance data for 22F return water temperature. Some data from similar GSHP systems in the area sure would sure help.. The paper I referenced above would help an engineer do the ground loop design since they did measure soil thermal transfer in 32F soil.

Alaskanoob, do you have performance data for 22F incoming water? That may greatly affect the heat output. Sorry I forgot that you will won't see 32F or better at 9-10 foot until late summer or fall. My mistake.

Another paper suggests that modest depth increases will not help in your near frozen soils.

Of course you're talking about the loop removing heat and over time in the winter that will cool the surrounding ground more than the ambient soil temp, so perhaps that is the issue you're discussing. But I would imagine the Fairbanks people up north would have had that issue too.

Lots of neighbors around her have root cellars that don't freeze in winter. Frost depth chart shows five feet for my location.

Also, my understanding is that oversizing the loop should also help keep the loop from having that freeze problem you were discussing. We are planning for a two ton unit, and 1000-1500 feet of loop.

I definitely need all the info I can get on this one because you're right about how important the soil temp is going to be. The Fairbanks test system supports your point. Year to year the loop started freezing the soil because it couldn't recharge enough in the summer. They ended up creating a big ice field over an 8 year span. But in the first couple years it worked great.

Last edited:

AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

I definitely will do that. I just want to come up with my best guess and some idea before I go to a contractor.I can tell you are not trained in geothermal, flow rates have everything to do with the heat transfer of a geothermal system, you need turbulent flow for good transfer.

Also more tube will not do anything after a certain point, once you have reached the capacity of the ground it doesn’t help to add more tube you can’t absorb more heat than is there, going over a 48” pitch slinky usually doesn’t gain much unless you are in very wet soil. You need more ditch length and then size the pumps for the extra head pressure.

I run into systems all the time that the contractor or home owner decided installing more tubing was better, most of the time it doesn’t mean more heat just a bigger pump station and less efficiency. You need more ditch, tubing and usually a larger pump station for added capacity.

To the OP get several quotes and get references from past jobs, design is critical on these systems. Take advice over the internet with a grain of salt. I have seen a lot of messed up jobs in my 32 years in HVAC, I have been a HVAC contractor for 20 years and design these systems for a living. I am also a IGSHPA certified designer/installer.

I have seen rules of thumb for minimum horizontal loop length but nothing about maximum. Any idea what the maximum length is or how to calculate it for our two-ton unit? I don't know how much it matters, but the elevation the loop is going is about the same as the cabin, within a few feet. Mostly a flat run.

AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

Our soil is thick grass soil for about a foot, then clay for about three feet, then a mix of sand and clay down from there. That's based on digging I've done and some guys driving piles down for a foundation. Ten feet down is sandy clay. We have very very few rocks here. It's rare to find one when I dig.You can’t size the unit based on its listed output it has to be able to absorb the heat from the ground and have enough off time for the ground to recoup.

The unit might be able to out put that BTU rating at 32 degree incoming water temp but if the unit doesn’t have long enough off cycles it will continue to pull the ground temp lower until the unit fails on high head pressure.

People think it is all about the equipment but the loop field is the most important design aspect. I can’t give you advice on the size of equipment or loop field, it is really location specific. We haven’t even talked about the type of soil you have at 10’ of depth, clay, sand, rock it can make a huge difference on your heat transfer.

I agree it is best to educate yourself as well as possible before dealing with contractors. I'm not competent to help with the ground source design for your area. With a frost line of (edit) 5 foot, I expect your soil temp at 9 or 10 foot will be much better than 32F. In most areas in the lower states, 12 foot depth gives you a stable year round temperature average, 10 foot deep varies only a little, and much delayed, seasonally. Since you have an excavator you can answer the soil temp question yourself by digging a deep hole and immediately measuring soil temp. I did mine when the septic perk test was done. Water temperature from a nearby well, after running for 10 minutes is also a way to get close. Some state data may be available as well. Clay sand mix will vary wildly depending on percent clay and moisture levels, but it does make for easy digging if there's enough clay to not have sidewalls collapse. I have the same here.

S Davis's and Kornbread's concern about local service and repair seems right on the mark to me. Reaching out to see what resources are locally available and what systems they have built locally that you might visit could be very useful.

S Davis's and Kornbread's concern about local service and repair seems right on the mark to me. Reaching out to see what resources are locally available and what systems they have built locally that you might visit could be very useful.

Last edited:

S Davis

Solar Enthusiast

- Joined

- Sep 25, 2021

- Messages

- 598

I had a job that I got called out to try and fix, I pulled up to the house that had a huge circular entry drive with a very large fountain in the middle. The first thing that caught my eye was the fountain tilted to one side, the installing contractor had installed some of the loops under the front drive and the system pulled the ground temp down and caused frost heaving.I appreciate all that information. Can you tell me where you are getting you soil temp data from? Alaska is a huge state with a lot of temperature differential so you may be thinking I'm up north. From the Alaska energy folks I've talked to in Fairbanks (which is much colder than where I am) they told me to make sure the unit can handle 32F temps. They have a horizontal ground loop in Fairbanks and have done some reports on it and they indicate that the temp only nine feet down maintained about 32F during winter. Our location is much warmer in the winter and cooler in the summer. So while our winters are more mild than their winters, we don't get the recharge they get in the summer.

Of course you're talking about the loop removing heat and over time in the winter that will cool the surrounding ground more than the ambient soil temp, so perhaps that is the issue you're discussing. But I would imagine the Fairbanks people up north would have had that issue too.

Lots of neighbors around her have root cellars that don't freeze in winter. Frost depth chart shows five feet for my location.

Also, my understanding is that oversizing the loop should also help keep the loop from having that freeze problem you were discussing. We are planning for a two ton unit, and 1000-1500 feet of loop.

I definitely need all the info I can get on this one because you're right about how important the soil temp is going to be. The Fairbanks test system supports your point. Year to year the loop started freezing the soil because it couldn't recharge enough in the summer. They ended up creating a big ice field over an 8 year span. But in the first couple years it worked great.

Nice project, not sure I would try that in that environment but..

We are in Pa, completely different animal and we use a sanden CO2 air to water heatpump , normally for domestic hot water but we use it for our radiant heating... 3/4 pex under two layers of hardwood floor.

We have a 52 x36 shop behind the house that is build slab on sand.. floor heating as well . ,4" of insulation below slab that extends 3 feet beyond the perimeter.. this keeps the frost away from the slab to avoid heaving and cracking. Our local building code had big problems with that theory and design..

It is there now for 15 years and no cracking or heaving.. so far for experts..

Just an idea to explore.. to prevent the frost getting into the ground from above you could lay insulation over your field like at 2 to 4 feet deep and potential along the outer edge of the field , maybe 8ft deep.. probably expensive in material but a diy solution.

Coming back on the sanden CO2 heatpump, maybe with your low ground temp you could use a sanden CO2 equipped with a liquid heat exchanger on the cold side and an antifreeze coolant in your loop. Not that sanden will support you, even my simple floor heating made them raise their eyebrows, haha.

I would imagine that the heat capacity of wet ground is hugely less when it actually becomes frozen, the phase change delivers a large amount of heat.

If you are able to insulate your field then you will be able to dump heat into it during the summer and use it a storage...several projects like that have been done in Canada ( village on solar collectors ) and Germany.

I doubt that you can find an expert with 100 plus installs in you area so better trust yourself .

Good luck, hope you pull it off.

Johan

We are in Pa, completely different animal and we use a sanden CO2 air to water heatpump , normally for domestic hot water but we use it for our radiant heating... 3/4 pex under two layers of hardwood floor.

We have a 52 x36 shop behind the house that is build slab on sand.. floor heating as well . ,4" of insulation below slab that extends 3 feet beyond the perimeter.. this keeps the frost away from the slab to avoid heaving and cracking. Our local building code had big problems with that theory and design..

It is there now for 15 years and no cracking or heaving.. so far for experts..

Just an idea to explore.. to prevent the frost getting into the ground from above you could lay insulation over your field like at 2 to 4 feet deep and potential along the outer edge of the field , maybe 8ft deep.. probably expensive in material but a diy solution.

Coming back on the sanden CO2 heatpump, maybe with your low ground temp you could use a sanden CO2 equipped with a liquid heat exchanger on the cold side and an antifreeze coolant in your loop. Not that sanden will support you, even my simple floor heating made them raise their eyebrows, haha.

I would imagine that the heat capacity of wet ground is hugely less when it actually becomes frozen, the phase change delivers a large amount of heat.

If you are able to insulate your field then you will be able to dump heat into it during the summer and use it a storage...several projects like that have been done in Canada ( village on solar collectors ) and Germany.

I doubt that you can find an expert with 100 plus installs in you area so better trust yourself .

Good luck, hope you pull it off.

Johan

AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

Thanks for passing on the learned experience. I think our soil ten feet down is warmer than 32F from all the data I've seen. But the loop over time making that soil colder could be an issue. Our cabin doesn't get hot in the summer so there isn't any reason to cool the cabin and return heat to the loop, but maybe we can open up our windows in the summer and set the cooling to 50F or something just to make the unit transfer heat back into the ground loop. We'll have more energy in the summer than we know what to do with, so perhaps that is a strategy to keep the ground recharged.Nice project, not sure I would try that in that environment but..

We are in Pa, completely different animal and we use a sanden CO2 air to water heatpump , normally for domestic hot water but we use it for our radiant heating... 3/4 pex under two layers of hardwood floor.

We have a 52 x36 shop behind the house that is build slab on sand.. floor heating as well . ,4" of insulation below slab that extends 3 feet beyond the perimeter.. this keeps the frost away from the slab to avoid heaving and cracking. Our local building code had big problems with that theory and design..

It is there now for 15 years and no cracking or heaving.. so far for experts..

Just an idea to explore.. to prevent the frost getting into the ground from above you could lay insulation over your field like at 2 to 4 feet deep and potential along the outer edge of the field , maybe 8ft deep.. probably expensive in material but a diy solution.

Coming back on the sanden CO2 heatpump, maybe with your low ground temp you could use a sanden CO2 equipped with a liquid heat exchanger on the cold side and an antifreeze coolant in your loop. Not that sanden will support you, even my simple floor heating made them raise their eyebrows, haha.

I would imagine that the heat capacity of wet ground is hugely less when it actually becomes frozen, the phase change delivers a large amount of heat.

If you are able to insulate your field then you will be able to dump heat into it during the summer and use it a storage...several projects like that have been done in Canada ( village on solar collectors ) and Germany.

I doubt that you can find an expert with 100 plus installs in you area so better trust yourself .

Good luck, hope you pull it off.

Johan

But what I really need to find out is how much of a horizontal ground loop is too much? I had been operating under the assumption that longer is always better but some people are indicating you can have too much. But I haven't seen anything on how to calculate what is too much. Longer is supposed to draw more energy from more ground to prevent turning the loop ground into ice over the winter, but I don't know what's too much if anything.

I think we're going to put in 1000-1500 feet and none of it will be slinky style since it seems to me slinky style has a greater chance of making an underground ice field.

Slinky has more surface area per cubic yard of soil.. so if it sucks more heat out of the soil then can be replenished it will freeze up.. that is why I mean with experts.. I am sure they had a whole bunch of experts that did not see that coming...

But alas, we learn from other people's mistakes, experts or not .

The turbulence versus laminar in these application is about 8 percent more efficient but that does not mean anything if the soil can not replenish the heat. Also above 1.1 cfm in 3/4" tube around 32f you will almost always have turbulence.

The buty of the internet is that with a day of studying you will have " more " expertise then the experts themselves

How big of a square area do you have to work with? Maybe a large trencher would be nice and efficient to use.

Go multiple parallel loops to keep pumping losses down, lower liquid speeds allow more time to absorb,

If you are going solar then likely you have a lot of overcapacity during the summer, a second air to air heatpump heat exchanger outside the house would allow you to cool the outside of your house and start heating your soil..

Maybe you can add a super heater to your heatpump to make hot water.. give floor heat a thought , pex is cheap, ( if you diy) and warm feet has a psychological effect... very efficient...

How much solar do you have installed and how many kWh do you think you get out of it during the winter?

But alas, we learn from other people's mistakes, experts or not .

The turbulence versus laminar in these application is about 8 percent more efficient but that does not mean anything if the soil can not replenish the heat. Also above 1.1 cfm in 3/4" tube around 32f you will almost always have turbulence.

The buty of the internet is that with a day of studying you will have " more " expertise then the experts themselves

How big of a square area do you have to work with? Maybe a large trencher would be nice and efficient to use.

Go multiple parallel loops to keep pumping losses down, lower liquid speeds allow more time to absorb,

If you are going solar then likely you have a lot of overcapacity during the summer, a second air to air heatpump heat exchanger outside the house would allow you to cool the outside of your house and start heating your soil..

Maybe you can add a super heater to your heatpump to make hot water.. give floor heat a thought , pex is cheap, ( if you diy) and warm feet has a psychological effect... very efficient...

How much solar do you have installed and how many kWh do you think you get out of it during the winter?

AlaskanNoob

Solar Enthusiast

- Joined

- Feb 20, 2021

- Messages

- 906

Thanks for the recommendation about multiple loops, I will give that a think.Slinky has more surface area per cubic yard of soil.. so if it sucks more heat out of the soil then can be replenished it will freeze up.. that is why I mean with experts.. I am sure they had a whole bunch of experts that did not see that coming...

But alas, we learn from other people's mistakes, experts or not .

The turbulence versus laminar in these application is about 8 percent more efficient but that does not mean anything if the soil can not replenish the heat. Also above 1.1 cfm in 3/4" tube around 32f you will almost always have turbulence.

The buty of the internet is that with a day of studying you will have " more " expertise then the experts themselves

How big of a square area do you have to work with? Maybe a large trencher would be nice and efficient to use.

Go multiple parallel loops to keep pumping losses down, lower liquid speeds allow more time to absorb,

If you are going solar then likely you have a lot of overcapacity during the summer, a second air to air heatpump heat exchanger outside the house would allow you to cool the outside of your house and start heating your soil..

Maybe you can add a super heater to your heatpump to make hot water.. give floor heat a thought , pex is cheap, ( if you diy) and warm feet has a psychological effect... very efficient...

How much solar do you have installed and how many kWh do you think you get out of it during the winter?

We have tons of space for loops, but most of our property is shaded by trees and terrain to the south and we have only one area that gets direct sun on 21 Dec. It's about two acres of south facing slope that gets the full four hours of direct sun we get on December 21st. No shading (except for trees). That's the lowest point of the sun and for most of the year we get far more sun than that given our long days including some days where the sun is up for about twenty hours.

But that south facing slope is about 500-600 feet from the cabin we're trying to heat. So we're going to trench ten feet down (we have an excavator) to the south facing slope and then add some loop there. At least that's the plan. I still have to nail down the data behind one or two people telling me that horizontal ground loops can be too long, so I don't know what the length limit actually is.

We're going to start with 10KW of bifacial solar panels on a ground mount installed on the south facing slope that will be straight up and down to keep snow off and to optimize them for the winter sun. We will be able to tilt them to 45 degrees or so for non-snow months. If we have to add more solar later we will do so but we're going to start with that and see how well it works.

The ClimateMaster Trilogy 45 Q-Series pump we're looking at includes a water heater for heating water.

Climate Master has an excel tool which does exactly what you are requesting:I definitely will do that. I just want to come up with my best guess and some idea before I go to a contractor.

I have seen rules of thumb for minimum horizontal loop length but nothing about maximum. Any idea what the maximum length is or how to calculate it for our two-ton unit? I don't know how much it matters, but the elevation the loop is going is about the same as the cabin, within a few feet. Mostly a flat run.

ClimateMaster - Home

ClimateMaster is the world’s largest and most progressive manufacturer of water source and geothermal heat pump systems for residential and commercial markets. We are committed to innovation and dedicated to environmentally clean, economically sound, and superbly comfortable home and business...

I am planning a post frame house in MN with geothermal, likely also a Climate Master unit. Have a video which describes a process for calculating soil temps at various depths throughout the year. Am revising the layout still (simpler, less windows, more insulation)

There is a soft-start device available for the climate master Tranquility (TE) series as well. It is called the "SecureStart™ Module". The major pro to the TE series is that it is available direct at https://www.iwae.com. The TE does not have the dedicated hot water heat, but it can be setup with a de-superheater, which would consume some of the heating capacity during the winter for hot water heat.

Last edited:

RV10flyer

Solar Wizard

- Joined

- Mar 8, 2021

- Messages

- 1,198

HVAC contractor here. Insulate very well, build smaller. I have 2 ea 16 SEER 2 Ton AS HP’s and 1 ea 20 SEER 2 Ton Inverter AS HP systems. If you want simple, cheap to repair, easy to find an HVAC tech, buy 14 SEER then add soft start kits. You might need more solar, but you’ll have the extra money and solar doesn’t break as often. If you have lots of money to spend, go Geo.After living with a ground source heat pump as our primary heating source for ten years, we have seldom been so disappointed in an expensive, over-hyped piece of kit. It never delivered on energy savings. It has never been reliable (as I type this, we are again without heat and my feet are freezing). It cost three times what a 'regular' hvac cost.

Did we get a lemon? Is this simply the normal life of a ground source heat pumps ten years ago? Have things changed since then? Don't know, but I do know it would take a ton of first hand factual data before even remotely considering another gshp.

YMMV

Last edited:

OzSolar

Whatever you did, that's what you planned.

Sound advice. Spend less on the best locally available equipment then use that money on more solar gets my vote as well.HVAC contractor here. Insulate very well, build smaller. I have 2 es 16 SEER 2 Ton AS HP’s and 1 ea 20 SEER 2 Ton Inverter AS HP systems. If you want simple, cheap to repair, easy to find an HVAC tech, buy 14 SEER then add soft start kits. You might need more solar, but you’ll have the extra money and solar doesn’t break as often. If you have lots of money to spend, go Geo.

Some more thoughts to consider:

Has anyone mentioned mini-splits? Mine provide usable heat down to -14f in heat pump mode (no strips) but I cannot speak to what is going on with their COP at that temp. Maybe a good solution for the shoulder months? Pretty darn affordable, particularly if you can install them yourself and have a buddy that can come pull the vacuum on the line set.

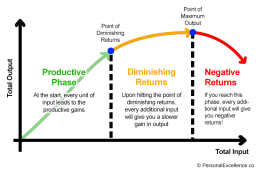

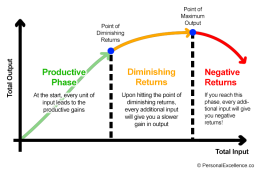

In my experience the law of dimensioning returns applies to a lot of energy efficiency projects, often to the point of negative returns. Of course if you're doing this mainly because you think it would be a fun (etc) project then carry on! Who am I to question how your spend your money?

I've been in the electrical side of the energy efficiency business for over 25 years. Mostly commercial but am around a lot of residential gear. No hard data to back this up but from what I've seen there comes a point where pulling out all the stops to get the most efficient system just ends up really biting you in the behind. IE: Spending $10K extra to get a system that costs $1k less per year run might sound great but all too often the most efficient gear is very finnicky and much more expensive to repair. IE: it takes 10 years to get that that upcharge back and then need a $4000 repair in year 12 is an all too often occurrence.

We had geothermal installed by a reputable contractor around 12 years ago and other than losing its ECM blower motor 1 month before the 10 warranty was up its been trouble free. We've really loved it. FWIW, it took them over a week to get that motor and we were miserable. If had been a regular heat pump the tech likely would have had it in on his truck. Had it not been under warranty they told me it would have approached $2000. 2 ton system with 2 x 300' closed loop wells. We paid $21k for it but the ARRA grant and Federal Tax Credit brought out final cost down to less than $4k. They quoted a 14 SEER air source at $8800 so had it been for the incentives we wouldn't have touched it. No strips, never even came close to needing them in relatively mild southern Missouri.

Good luck!

Attachments

Last edited: