Desert Mouse

New Member

Ugh. So I just finished installing my panels on the roof. For some dumb reason I thought it would be fine not the tighten the zip ties that are going to keep the wires from flopping around under the panels. I thought this wouldnt be a problem, I'll just reach under their with my long pliers and tighten em. Bad move. The zip ties I got turned out to be shit, and everyone one I tried immediatley broke. I took some out from the bag and every one snapped like a twig when I bent them.

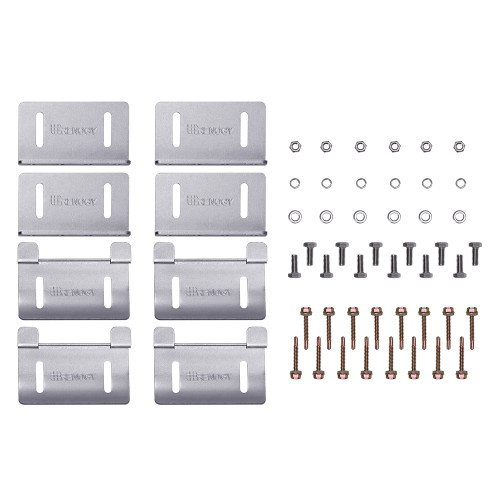

Great. So now I have to get under the panels. The renogy z brackets I used make this effectivley impossible. Has anyone come up with a method to remove just the panels? Or has found or jury rigged a tool that can hold that nut? I really dont want to remove the brackets and spend an entire day scraping dicor off, and its too cold where I am now to reseal them anyway.

Now if I can actually get these things off; I found another thread where someone mentioned using rivnuts to reattach the panels to the bracket. Which I think is just brilliant, but are the nuts going to be strong enough?

Great. So now I have to get under the panels. The renogy z brackets I used make this effectivley impossible. Has anyone come up with a method to remove just the panels? Or has found or jury rigged a tool that can hold that nut? I really dont want to remove the brackets and spend an entire day scraping dicor off, and its too cold where I am now to reseal them anyway.

Now if I can actually get these things off; I found another thread where someone mentioned using rivnuts to reattach the panels to the bracket. Which I think is just brilliant, but are the nuts going to be strong enough?