SubnetMask

New Member

- Joined

- Dec 6, 2021

- Messages

- 27

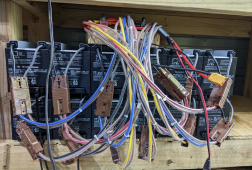

I just acquired several UPS external expansion batteries that were BNIB, never been attached to a UPS, but have been sitting in box on a pallet for 'several years' - based on the manufacture date, I think somewhere around 2.5 years. So obviously, self-discharge is an issue. I was expecting them to be at like 11v per battery, which would likely be a tough recovery at best, but each pack worked out to 96-97v or so (each pack is 8s), and every battery I individually checked was 12.1-12.2v, which based on some charts I've seen, correlates to 75-80% DoD.

That being said, I'd like to try and resurrect these batteries - I can't use the packs as designed, but if they can be resurrected to full or near full capacity, I CAN use the batteries inside for my active UPS's as they're the exact same batteries, just a different configuration (16s2p for 192v on these vs 10s for my UPS's). If they can be resurrected and (those that I don't immediately use) can be kept optimal for years, the batteries involved could keep my main UPS's going for quite some time.

What's the best way to try and rejuvinate these batteries (charger, settings, etc)? I have a few NoCo Genius chargers - would these work? If so, what's the proper setting (there are several - standard, AGM, etc), or is there a better option, and if there is, what is that better option for this use case?

That being said, I'd like to try and resurrect these batteries - I can't use the packs as designed, but if they can be resurrected to full or near full capacity, I CAN use the batteries inside for my active UPS's as they're the exact same batteries, just a different configuration (16s2p for 192v on these vs 10s for my UPS's). If they can be resurrected and (those that I don't immediately use) can be kept optimal for years, the batteries involved could keep my main UPS's going for quite some time.

What's the best way to try and rejuvinate these batteries (charger, settings, etc)? I have a few NoCo Genius chargers - would these work? If so, what's the proper setting (there are several - standard, AGM, etc), or is there a better option, and if there is, what is that better option for this use case?