You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ryobi Zero-Turn Mower SLA to LiFePo4 Conversion - (Updated - Build Complete With Pics!)

- Thread starter AMDPower

- Start date

bobbie_ohio

New Member

- Joined

- Nov 23, 2021

- Messages

- 37

Yes I did, but I’m about to post a bad picture.Has anyone completed this conversion on non-zero turn model?

bobbie_ohio

New Member

- Joined

- Nov 23, 2021

- Messages

- 37

No idea what happened. Had been mowing for about 1h, stopped to feed my dog, came back out and was on it 10-15 more minutes when I looked at the bms app and saw way effed up numbers. Was going to get off to see if a monitor wire came off when it started smoking then poof some flames. Didn’t completely go up but this battery pack is pretty much effed. So sad. Not sure what happened. Will look tomorrow after it has tonight to cool off. App is still communicating so the bms appears ok for now. Never drew more than 91 amps. So bummed

UltrasoundJelly

New Member

- Joined

- Nov 16, 2021

- Messages

- 42

Dude, ugh. I'm sorry. Let us know what you find on the post-mortem.

Maybe it was just that one cell that kept going over-voltage?

Maybe it was just that one cell that kept going over-voltage?

Last edited:

UltrasoundJelly

New Member

- Joined

- Nov 16, 2021

- Messages

- 42

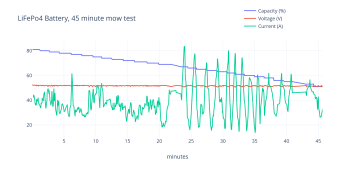

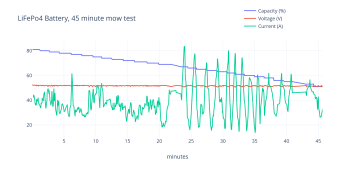

Here's data from my last battery discharge. Mowed the flat front yard first, then moved on to the steep slope of the backyard. Can you tell when the backyard mow started? Current is smoothed over 10 seconds or so. My battery is 100 Ah BTW. Interactive graph here.

wattmatters

Solar Wizard

Bummer.No idea what happened.

It's a tough, bumpy, dirty environment for a battery system to operate in. I would not be surprised if a terminal connection had loosened from the constant vibration, increasing resistance and resulting heat build up with high amp draw of cutting on an upslope. Coupled with flammable material getting everywhere just ready to catch alight.

Will be interesting to see what you find when you finally pull it apart.

bobbie_ohio

New Member

- Joined

- Nov 23, 2021

- Messages

- 37

It seems like 2 of the posts are scorched the most. It was my first time using it. After that first hour, maybe I should have checked tightness of connections before I started up again. Oh well, at least my ass didn't catch on fire.

Geez. But it ran fine on this model? Did you torque the terminals to spec?No idea what happened. Had been mowing for about 1h, stopped to feed my dog, came back out and was on it 10-15 more minutes when I looked at the bms app and saw way effed up numbers. Was going to get off to see if a monitor wire came off when it started smoking then poof some flames. Didn’t completely go up but this battery pack is pretty much effed. So sad. Not sure what happened. Will look tomorrow after it has tonight to cool off. App is still communicating so the bms appears ok for now. Never drew more than 91 amps. So bummed

View attachment 92874

Prefersdirt

Solar Enthusiast

- Joined

- Sep 28, 2019

- Messages

- 377

I have a couple of extra commercial 60" Xmark zero turn mowers with bad or questionable engines, but the machines are solid otherwise. I don't have the time to reinvent the wheel to try converting them over to all electric

Where are you located? These sound interesting to work on.

rio

New Member

@bobbie_ohio, wow that is terrible news, really sorry to hear. Loose battery terminals is the first thing that came to mind. I torqued mine to 4 Nm (M6 aluminum), but now after reading what happened to you I'm going to open mine up and see if everything is still tight (perhaps everyone should do the same!). If this is in fact what happened then I would imagine most of your batteries are still fine. Glad that nobody got hurt. Please keep us posted.

cyberbandit1998

Tech Geek

- Joined

- Sep 17, 2021

- Messages

- 4

Hello all thanks for all the infomation. This blog help persuaded me to get the Ryobi 54in 48v, I was on the fence because of the SLA batteries. Now I got a plan to convert it lifepo4. Should arrive on Apr 9 and converted to lithium that weekend. My question is the price of prismatic cell are crazy right now. I am looking and the price will be around 1200-2000 for 16 raw cells, or I can get drop in for around 1400-1600. Is there any advantages to diy my battery vs drop in from good old Amazon? Also if any one has a US raw cell seller that got good prices please share.

Being able to pick your bms is a huge plus imo. I’m going with the electrodacus once I have to change out batteries. I have one in my van and it’s honestly perfect for me.Hello all thanks for all the infomation. This blog help persuaded me to get the Ryobi 54in 48v, I was on the fence because of the SLA batteries. Now I got a plan to convert it lifepo4. Should arrive on Apr 9 and converted to lithium that weekend. My question is the price of prismatic cell are crazy right now. I am looking and the price will be around 1200-2000 for 16 raw cells, or I can get drop in for around 1400-1600. Is there any advantages to diy my battery vs drop in from good old Amazon? Also if any one has a US raw cell seller that got good prices please share.

cyberbandit1998

Tech Geek

- Joined

- Sep 17, 2021

- Messages

- 4

I am looking at calb cells from Battery EVO. Are Calb cells taller that normal prismatic and can anyone tell me if they will fit in the area the old sla battery are, or can I get 2x https://signaturesolar.com/eg4-8-cell-pack-lithium-cells-25-6v-100ah/ and fix sideby side a better option?

icenov

New Member

I don't know about the Calb cells but the cells I used were 7.9 in high and by the time you added a bit of space for lugs it was a very close vertical fit. My box external dimensions are 8.7 high, 14.1 wide and 20 in long. I had no clearance on the width - just fitted, and almost no clearance on the top after adding a thin acrylic sheet. There was a lot of unused length though.I am looking at calb cells from Battery EVO. Are Calb cells taller that normal prismatic and can anyone tell me if they will fit in the area the old sla battery are, or can I get 2x https://signaturesolar.com/eg4-8-cell-pack-lithium-cells-25-6v-100ah/ and fix sideby side a better option?

rio

New Member

Not

Not me, should have thought of that. Most lock nuts are stainless steel, which worry me might significantly reduce conductivity between posts and bus bars. Found these aluminum ones, a bit pricy but might just get them: https://www.amazon.com/Flanged-Nylock-Self-lock-Aluminum-Silver/dp/B07K5CJZKH.So, high vibration application - you guys are using Nylock nuts right?

And possibly braided interconnects instead of rigid bus bars? Depending on how badly your bank is bouncing / allowing for movement...

UltrasoundJelly

New Member

- Joined

- Nov 16, 2021

- Messages

- 42

Me neither, but this is a great idea. I’m going to order these. Anyone have a line on some high gauge m6 ring terminal braided interconnects for cheap, or do I just need to bite the bullet and buy a hydraulic crimper and build them myself?Not

Not me, should have thought of that. Most lock nuts are stainless steel, which worry me might significantly reduce conductivity between posts and bus bars. Found these aluminum ones, a bit pricy but might just get them: https://www.amazon.com/Flanged-Nylock-Self-lock-Aluminum-Silver/dp/B07K5CJZKH.

Hedges

I See Electromagnetic Fields!

- Joined

- Mar 28, 2020

- Messages

- 21,047

Not

Not me, should have thought of that. Most lock nuts are stainless steel, which worry me might significantly reduce conductivity between posts and bus bars. Found these aluminum ones, a bit pricy but might just get them: https://www.amazon.com/Flanged-Nylock-Self-lock-Aluminum-Silver/dp/B07K5CJZKH.

Don't worry about conductivity. Path length and cross section mean negligible current through threaded studs/bolts and nuts.

Aluminum is a great conductor but native oxide is a horrible conductor. Bare aluminum should never be used as a conductor unless there is a process to get through the oxide and make conduct to underlying metal. You hopefully deal with flat surface where busbars contact, but you're not doing anything about surface of threads.

Me neither, but this is a great idea. I’m going to order these. Anyone have a line on some high gauge m6 ring terminal braided interconnects for cheap, or do I just need to bite the bullet and buy a hydraulic crimper and build them myself?

You probably can't find such with the length you want. I see terminals crimped to copper braid for ground straps; you could do that. We think tinned terminals would be better for direct contact with aluminum than bare copper. (of course remove aluminum oxide and use corrosion inhibitor.

I bought some pre-crimped battery cables for my AGM bank, and I've bought MC cables and cut in half for pigtails.

Hydraulic crimpers are now available in the $30 to $80 range, main problem is die sizes are random. I have the Harbor Freight one, and for some sizes it mashes out ears. But 8 tons or whatever certainly crimps hard. Maybe adjusting die size with a grinder to match a specific terminal would help.

Some people have pointed out sets (hydraulic and mechanical) which worked better than others. I think some mechanical (Temco?) crimpers in the <$300 range were said to be good, and there may have been some with self-adjusting die.

Well I've gone ahead and started my conversion process. I've purchased 4 CHINS 12.8V 100AH batteries from amazon.com (link here). I have a couple weeks before they arrive so I've got time to get the rest of what will be needed together. That's where you all come in  I've got several questions!

I've got several questions!

First - top balancing (necessary step?)

Since each of the 4 batteries have their own cells and BMS I'll be needing to buy a 12V charger to charge each up individually. I've been watching Will Prowse on YouTube and this is what I believe he recommends. I've found a victron energy 12v/5a charger (link here). I don't necessarily care about charging speed since I'll only be using these to charge up to 100% before putting these batteries together into 48V. Good charger?

Second - 4 batteries 100% charged put in parallel (again is this a necessary step?)

What hardware (wire/lugs/etc) will be needed? To connect each battery together in parallel after charging each to 100% you connect each of the positives together and the negatives together (correct)? This is still a 12v battery at this point right? Do they automatically balance between each being in parallel or do I need to dischage/recharge them?

Third - 4 batteries 100% charged, top balanced, and put into series

I can wire each of the 4 batteries in series and create a 48V 100 AH battery. I'll then need a 48V charger to charge the battery. How does this charger look (link here)? Since this is for my lawn mower I don't really care about speed, but having 100 AH to charge I don't want it to take days upon days...

Sorry for the lengthy post. I've read this entire thread and learned a lot and I'm ready to start on my own "drop in" project. The SLA's the RYOBI used a total garbage. They replaced my initial set and upon unboxing and testing the best battery health I had was 66%. Sigh. I'm going to give them away or see about recycling them at a nearby place. I want my mower to mow... I'm tired of fighting the batteries. I want to solve the problem and get to using it as a tool.

Appreciate everyone's comments, thoughts, and opinions It's why I signed up for an account.

It's why I signed up for an account.

First - top balancing (necessary step?)

Since each of the 4 batteries have their own cells and BMS I'll be needing to buy a 12V charger to charge each up individually. I've been watching Will Prowse on YouTube and this is what I believe he recommends. I've found a victron energy 12v/5a charger (link here). I don't necessarily care about charging speed since I'll only be using these to charge up to 100% before putting these batteries together into 48V. Good charger?

Second - 4 batteries 100% charged put in parallel (again is this a necessary step?)

What hardware (wire/lugs/etc) will be needed? To connect each battery together in parallel after charging each to 100% you connect each of the positives together and the negatives together (correct)? This is still a 12v battery at this point right? Do they automatically balance between each being in parallel or do I need to dischage/recharge them?

Third - 4 batteries 100% charged, top balanced, and put into series

I can wire each of the 4 batteries in series and create a 48V 100 AH battery. I'll then need a 48V charger to charge the battery. How does this charger look (link here)? Since this is for my lawn mower I don't really care about speed, but having 100 AH to charge I don't want it to take days upon days...

Sorry for the lengthy post. I've read this entire thread and learned a lot and I'm ready to start on my own "drop in" project. The SLA's the RYOBI used a total garbage. They replaced my initial set and upon unboxing and testing the best battery health I had was 66%. Sigh. I'm going to give them away or see about recycling them at a nearby place. I want my mower to mow... I'm tired of fighting the batteries. I want to solve the problem and get to using it as a tool.

Appreciate everyone's comments, thoughts, and opinions

Similar threads

- Replies

- 7

- Views

- 594

- Replies

- 3

- Views

- 1K

- Replies

- 1

- Views

- 405

- Replies

- 4

- Views

- 194

- Replies

- 26

- Views

- 7K