rafrojack

New Member

- Joined

- Sep 23, 2019

- Messages

- 28

Hi fellow van nomads,

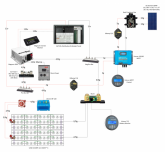

I've been knee deep in analysis over my electrical system for my van. Please take a look at the attached picture & let me know what needs to be changed! I've placed questions that I'm worried about in the same graphic. Positive criticism is needed! My main wickets to hit are:

1. More than enough power for two people.

2. Most up to date configuration on theory & parts.

3. Great quality parts & workmanship. Also, minimum # of parts/wiring without sacrificing safety & workmanship.

4. Shore power access & alternator b2b charger for emergencies.

Attached PDF in case you cannot zoom in well in enough.

Thank you for coming to my TEDVanLife talk.

I've been knee deep in analysis over my electrical system for my van. Please take a look at the attached picture & let me know what needs to be changed! I've placed questions that I'm worried about in the same graphic. Positive criticism is needed! My main wickets to hit are:

1. More than enough power for two people.

2. Most up to date configuration on theory & parts.

3. Great quality parts & workmanship. Also, minimum # of parts/wiring without sacrificing safety & workmanship.

4. Shore power access & alternator b2b charger for emergencies.

Attached PDF in case you cannot zoom in well in enough.

Thank you for coming to my TEDVanLife talk.