lt170chevelle

New Member

Hello, new guy here. Been off grid for over a year now on my ever expanding solar setup. Been trying to figure out if my system just is not big enough or something else. Like most beginners I have mostly cheaper end equipment. Would like to here any input or advice on this setup on why it isn't keeping up or what solutions I may need to pursue.

5 powmr 60a mppt solar chargers

25 various brand 100ah LI 12v batteries wired parallel

Right around 4000 watts of solar array single faced 100w panels and one 200w panel on each string ,wired in parallel, with exception of 3 250w bifacial wired in series to one dedicated controller

Also have one of the useless small wind turbines with a mppt controller on it. "400watt" but likely less than 100w true output

2000w sine wave inverter

My current load/usage is 350w-400w constantly 24hrs a day.

Sunny days all charge controllers and inverter show a good 13.5v all day, but overnight the battery bank gets drained and system shuts down.

I've been slowly adding batteries as I can afford them but I just did the math and it seems should have more than enough to handle the usage.

Any advice greatly appreciated.

5 powmr 60a mppt solar chargers

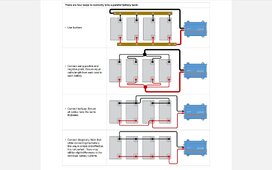

25 various brand 100ah LI 12v batteries wired parallel

Right around 4000 watts of solar array single faced 100w panels and one 200w panel on each string ,wired in parallel, with exception of 3 250w bifacial wired in series to one dedicated controller

Also have one of the useless small wind turbines with a mppt controller on it. "400watt" but likely less than 100w true output

2000w sine wave inverter

My current load/usage is 350w-400w constantly 24hrs a day.

Sunny days all charge controllers and inverter show a good 13.5v all day, but overnight the battery bank gets drained and system shuts down.

I've been slowly adding batteries as I can afford them but I just did the math and it seems should have more than enough to handle the usage.

Any advice greatly appreciated.