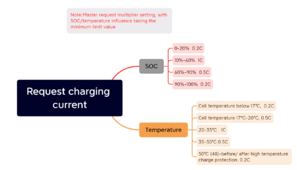

I had the same question and got an excellent response from Shaun at Sol-Ark:

The 15K-2P-N reaches a max battery charge/discharge of 275A if using both sets of battery terminals.

If only one set of terminals is used, the max battery charge/discharge will be limited to 160A.

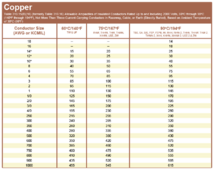

If you have x2 (#2/0 AWG) cable pairs from the battery bank busbars, then yes! Hook ++ cables to the two positive terminals on the inverter, and -- cables to the negative terminals.

275A is too large for a single terminal post, since each post is rated for 160A, and #4/0AWG Cable is not rated up to 275A, so the correct way to IS to use both terminal posts and #2/0.

If each battery has it's own pair of cables (+ & -) but the batteries are NOT combined to busbars (++ & --) then you should probably terminate each battery cable at a busbar for ++ and a separate busbar for -- and then have a pair of #2/0AWG conductors from each busbar to each corresponding battery terminal at the inverter. This is a "best practice" to ensure even power distribution and battery exercise (and to avoid developing imbalance issues over time).

For connecting a single #4/0 AWG cable to the inverter posts you would use a terminal busbar:

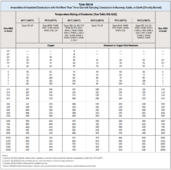

View attachment 197421

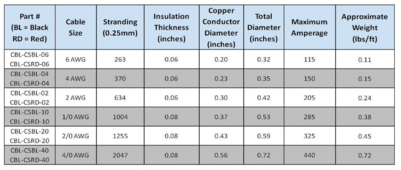

x2 (#2/0 AWG) Conductors: <380A @<90°F thin-strand copper

x1 (#4/0 AWG) Conductors: <260A @<90°F thin-strand copper

Check your planned Wire Ampacity:

View attachment 197422