I little background info

I am using this thread as a Show and Tell, but my main reason is, it is a vlog of my build thread where I log pertainent information on what, why, and how I did things. It serves as my long term memory. I also save this pages locally so that I have a backup in case we lose this web site, heaven forbid

I was able to accomplish re-attachment of the Charge Controller #1 which manages array #1, obviously

here is the series of pics of the wires coming in from the arrays, through the PDP and into the CC

Entry of the array feedlines enters this box, a re-purposed service panel, on its side

Each array has a relay/contactor which can interrupt incoming current. The controller that does is the

EVTV V2 Controller - Jack-In-The-Box ->>

https://store.evtv.me/products/esp32bms that is between the battery and the bus bars, and thus the inverter

This "jack-in-the-back" or JITB, monitors several attributes of the environment and the battery. If anything falls outside of (settable) parameters, the JITB shuts the entire battery system DOWN hard - it turns it off. One of the things that is shutdown down are the incoming charging streams from the arrays. It does this by operating a signal, which is called CHARGENABLE. Normally OPEN, when things are within parameters, it signals a CLOSE control, which I have wired to a normal 12v relay. When enabledl, it causes these 4 contactors to close, thus allowing charging current to enter into the system. If something is amiss this CHARGENABLE is disabled and the contactors OPEN. During normal operating conditions, these contactors are closed, allowing current to enter.

In the following pic, Array #1 wires enter the PDP on the left with a ground wire, and POS and NEG wires. This is the only ground wired between the contactor box and the PDP. Below that, I also have wired GRID AC IN to the AC breaker on the left

Following the installation instructions, incoming array POS wire enters the 60 amp DC breaker before being run to the CC. The return wire from the CC then enters the top of the next 80 amp DC breaker

Here a ground, the Array POS (coming from the 60 amp breaker) and the Array NEG enter the conduit to the CC #1. A returning POS and NEG come back the same way

here the incoming and outgoing wires from within the CC, a ground is attached at the back wall. This a difficult small space to set these wires, for sure

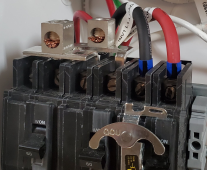

this the bottom of the 60/80 amp pair of breakers for CC #1

on the left is the exit wire from the 60 amp, that goes to the CC, and the next one to the right is the exit wire from the 80 amp breaker. This one then goes to the common POS battery bus bar, coming up next

www.harborfreight.com

www.harborfreight.com