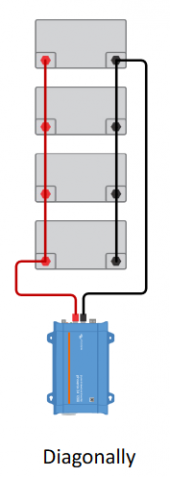

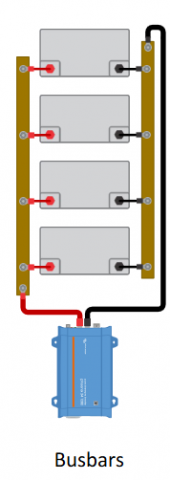

Watching David Poz's video about using bus bars to solve parallel resistance issues it seemed like a more complex and less than ideal solution to me.

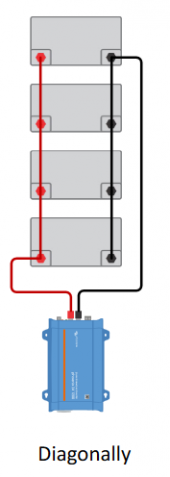

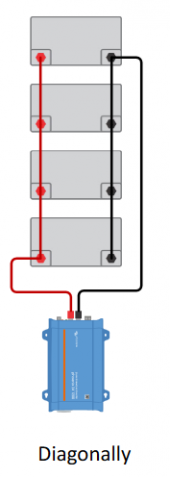

I thought daisy chaining with cables using a dual cable crimp lug would eliminate extra connections and the bus bar completely, as well as solve his issues with using a solid bus bar directly on the terminals. Did some searching and found "stackable lugs" which seem perfect for the job. https://spectrowireandcable.com/c/battery-lugs/mega-lugs-stackable/

Has anyone used these?

I thought daisy chaining with cables using a dual cable crimp lug would eliminate extra connections and the bus bar completely, as well as solve his issues with using a solid bus bar directly on the terminals. Did some searching and found "stackable lugs" which seem perfect for the job. https://spectrowireandcable.com/c/battery-lugs/mega-lugs-stackable/

Has anyone used these?