Has anyone used these flexible solar panels by top solar? Do you like them? They recently dropped in price! Going to put 2 of the 100 watt ones on top of a cargo box. https://www.amazon.com/gp/product/B08MKSG4B9/ref=ox_sc_act_title_3?smid=A3AL79HK0411E6&psc=1

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Topsolar Brand flexible solar panels?

- Thread starter Jet

- Start date

sunshine_eggo

Happy Breffast!

No experience with that brand, but when buying flexible, you want ETFE, and those qualify. HOWEVER, ETFE panels typically have a much longer warranty - 5 years defect and 20+ years performance. These are only warrantied for a year.

I would be a little dubious of the ETFE claim in that light.

I would be a little dubious of the ETFE claim in that light.

I didn't realize they had any warranty. I need the solar to be 24v, lightweight as they are going in top of a not flat cargo box mounted on a flimsy station wagon roof rack. I like those perticular panels because they have good Amazon rating, their cheap, all black will look good with cargo box and blend in more. I'm only buying 2. There not what I would use to build a huge long term system. If they last just a few years I won't complain.

sunshine_eggo

Happy Breffast!

I didn't realize they had any warranty. I need the solar to be 24v, lightweight as they are going in top of a cargo box mounted on a flimsy frame. I like those perticular panels because they have good Amazon rating, their cheap, all black will look good with cargo box and blend in more. I'm only buying 2. There not what I would use to build a huge long term system. If they last just a few years I won't complain.

Given your criteria, and their relatively low cost (not much more than rigid panels), it's probably worth the risk, but I would lower my expectations to 1 year max.

ghostwriter66

"Here - Hold my Beer"

Flexible panels are awful .... you put them down on the surface ... they can't dissipate heat - within about 120 days they are cracking and shutting down .... I have found no one that has had success with it .. also - right out of the box they will probably only give you 50%of the rated wattage ... and its downhill from there ... just my opinion

meetyg

Solar Enthusiast

- Joined

- Jun 4, 2021

- Messages

- 1,093

I don't have this specific brand, but I have 4x100w of similar black ETFE panels.

What can I say, they are pretty lousy.

I'm only getting around 180w peak from 400w total.

I got them mounted on a "wing" if my pergola. They have some airflow underneath, but sill they get hot pretty quickly and the output is greatly reduced.

These black ones seem to overheat faster than other types.

If you have to use flexible panels, I would suggest the ones that use "Sunpower" type cells.

These cells are less prone to cracking, and have a nice output. Also, their white backing seems to collect less heat than the black ones.

They look like this:

These are actually my oldest ones. They are used to run some auxiliary things, so I don't have exact parameters as to their output, but they seem to hold up pretty well (ignore the fact that they are dirty).

What can I say, they are pretty lousy.

I'm only getting around 180w peak from 400w total.

I got them mounted on a "wing" if my pergola. They have some airflow underneath, but sill they get hot pretty quickly and the output is greatly reduced.

These black ones seem to overheat faster than other types.

If you have to use flexible panels, I would suggest the ones that use "Sunpower" type cells.

These cells are less prone to cracking, and have a nice output. Also, their white backing seems to collect less heat than the black ones.

They look like this:

These are actually my oldest ones. They are used to run some auxiliary things, so I don't have exact parameters as to their output, but they seem to hold up pretty well (ignore the fact that they are dirty).

Last edited:

ianganderton

Auckland, NZ

Flexible panels are fine if not mounted permenantly. They suit the solar suitcase use best as they are light. Only use them when you need them.

Mounted on a surface they over heat and cook

Mounted on a surface they over heat and cook

Thanks for your input. Did you make a "show and tell" post of your installation? It is one of my main interests at this moment seeing that I have a similar installation on my balcony. The flexible panels I bought from Ali were expected to do much less than stated. From 200W I can get 100W in sunny winter, 120W in spring and perhaps 140W in summer.I don't have this specific brand, but I have 4x100w of similar black ETFE panels.

What can I say, they are pretty lousy.

I'm only getting around 180w peak from 400w total.

I got them mounted on a "wing" if my pergola. They have some airflow underneath, but sill they get hot pretty quickly and the output is greatly reduced.

These black ones seem to overheat faster than other types.

View attachment 71810

If you have to use flexible panels, I would suggest the ones that use "Sunpower" type cells.

These cells are less prone to cracking, and have a nice output. Also, their white backing seems to collect less heat than the black ones.

They look like this:

View attachment 71805

These are actually my oldest ones. They are used to run some auxiliary things, so I don't have exact parameters as to their output, but they seem to hold up pretty well (ignore the fact that they are dirty).

After 3 months the panels look as new, but I am aware that in 1 year it won't be the case, specially after summer. The panels are placed on a frame and naked on the back, which together with the altitude of my balcony and the area weather helps them to stay fairly ventilated all throughout the year.

What I do get already is issues with the MC4 connectors (corrosion).

meetyg

Solar Enthusiast

- Joined

- Jun 4, 2021

- Messages

- 1,093

No, I didn't do a show and tell...Thanks for your input. Did you make a "show and tell" post of your installation? It is one of my main interests at this moment seeing that I have a similar installation on my balcony. The flexible panels I bought from Ali were expected to do much less than stated. From 200W I can get 100W in sunny winter, 120W in spring and perhaps 140W in summer.

After 3 months the panels look as new, but I am aware that in 1 year it won't be the case, specially after summer. The panels are placed on a frame and naked on the back, which together with the altitude of my balcony and the area weather helps them to stay fairly ventilated all throughout the year.

What I do get already is issues with the MC4 connectors (corrosion).

But here are some pics:

I have 4 x 100w flexible panels (max output is 200w, which is odd). They are attached to the "wing" of my pergola. The back side is somewhat ventilated, as the pergola wing is made of wood planks with some space between them. They are at approximately a 45° angle, facing East (as the pergola is). They give some early morning power, until the sun is high enough for the two (one is shown in the first pic) additional 455w (360w peak actual) glass panels that lay fairly flat on the top of the pergola (between 10-15° angle).

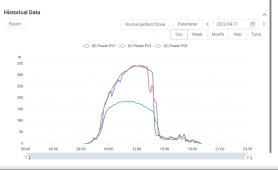

Here is an example graph of my power produced on a good day, recently (pv1 an overview are the 455w glass panels, pv3 is the array of 2s2p flexible panels):

Last edited:

My understanding is that UV in sun breaks the polymeric chains in plastic which as result takes away its properties such as elasticity. Then the thermal expansion/compression from the sun and weather add tension to the material which results in micro-cracking. If an old solar panel is slightly bended due to movement/wind/rain then the visible part of this process is accelerated. Glass does not have this issues; does not degrade with UV.

Most high performance plastics or either are UV resistant by nature or get a UV resistant coating. Not sure that for solar this is possible

Most high performance plastics or either are UV resistant by nature or get a UV resistant coating. Not sure that for solar this is possible

I have my flexible panels at 35 degrees as I wanted to capture more of the summer sun. The winter one is weaker. It is very disappointing that from 400W you only get 180-200W; my output is also low but your even lower; could the cables shadows influence that output?No, I didn't do a show and tell...

But here are some pics:

View attachment 90896

I have 4 x 100w flexible panels (max output is 200w, which is odd). They are attached to the "wing" of my pergola. The back side is somewhat ventilated, as the pergola wing is made of wood planks with some space between them. They are at approximately a 45° angle, facing East (as the pergola is). They give some early morning power, until the sun is high enough for the two (one is shown in the first pic) additional 455w (360w peak actual) glass panels that lay fairly flat on the top of the pergola (between 10-15° angle).

View attachment 90897

Here is an example graph of my power produced on a good day, recently (pv1 an overview are the 455w glass panels, pv3 is the array of 2s2p flexible panels):

View attachment 90898

The other glass panels you have are doing much better.

meetyg

Solar Enthusiast

- Joined

- Jun 4, 2021

- Messages

- 1,093

I have measured voltages on both arrays of flexible panels, and it's correct (around 36v VOC per 2 panels in series), so I don't think it's shading. The problem is I'm only getting only 2.5 amps maximum from each parallel branch, when they should be 5 amps each.I have my flexible panels at 35 degrees as I wanted to capture more of the summer sun. The winter one is weaker. It is very disappointing that from 400W you only get 180-200W; my output is also low but your even lower; could the cables shadows influence that output?

The other glass panels you have are doing much better.

I am using two different brands of panels (although spec wise they are identical). Basically each series string is comprised of two different brands.

I suspect that maybe one brand is bringing down the other brand. But in order to put each brand in its own series I would have to move them around, or use longer cables (just for checking). I haven't had the time to fiddle with it, but something isn't working properly for sure.

What you could do to clear any doubt is to take one panel out and test it in an open area during a sunny day. Then you can test any kind of angle or orientation and find the max. power output of one panel. But If you can't apply changes to the angle or orientation of your panels, then all these efforts go just to knowledge but no more watts.I have measured voltages on both arrays of flexible panels, and it's correct (around 36v VOC per 2 panels in series), so I don't think it's shading. The problem is I'm only getting only 2.5 amps maximum from each parallel branch, when they should be 5 amps each.

I am using two different brands of panels (although spec wise they are identical). Basically each series string is comprised of two different brands.

I suspect that maybe one brand is bringing down the other brand. But in order to put each brand in its own series I would have to move them around, or use longer cables (just for checking). I haven't had the time to fiddle with it, but something isn't working properly for sure.

Also, being "old" flexible panels, better not to manipulate them much. The plastic can become brittle due to UV exposure.

Here the post of my flexible panels (just in case you did not see):

https://diysolarforum.com/threads/balcony-solar-200w-grid-tied.36842/

It seems like it's a good Idea to experiment with temperature balansing, Uv-filters, and epoxying onto harder surfaces to get a longer life span out of these. Especially if you plan to build something expensive with over 1000 cells.My understanding is that UV in sun breaks the polymeric chains in plastic which as result takes away its properties such as elasticity. Then the thermal expansion/compression from the sun and weather add tension to the material which results in micro-cracking. If an old solar panel is slightly bended due to movement/wind/rain then the visible part of this process is accelerated. Glass does not have this issues; does not degrade with UV.

Most high performance plastics or either are UV resistant by nature or get a UV resistant coating. Not sure that for solar this is possible

I have had great success with it, but then again I don't buy consumer-grade garbage. PowerFilm exhibits none of these behaviors. With quality-grade, you *can* get the rated output (or at least as close as you can with the sun overhead at noon, no clouds or haze etc)Flexible panels are awful .... you put them down on the surface ... they can't dissipate heat - within about 120 days they are cracking and shutting down .... I have found no one that has had success with it .. also - right out of the box they will probably only give you 50%of the rated wattage ... and its downhill from there ... just my opinion

Nor do I expect them to live 20 years, nor put them into a permanently mounted situation, but those kind of results shown above come from possibly being enticed by the very low end of the garbage pile.

In addition, proper engineering is just the same as with other panels. Wiring random ones in series? Better make sure that their voltages are within about 10% or less of each other. Watch for voltage drop / long run of thin cable a problem? You bet. No difference.

Mis-application, poor user-end engineering, and unreliable low-end garbage sellers are the main problem.

Yes, constant exposure to ultraviolet light makes the surrounding material, exposed wires and so forth degrade. Low-end flexible cells do likewise. Higher quality ones last longer.Can anybody explain why semi flexible cells degrade so fast?

How are they made? I don't want to use hard wafer cells because of weight and brittleness concern. Also they are time consuming to solder.

The ones we can get a hold of are typically NOT meant to be a permanent solution. The tip here is that when you aren't actually using them, cover them up. Ie, if you are a weekend warrior, don't leave the panels exposed to the sun the rest of the week doing nothing - you'll get more life.

How they are actually made can be found elsewhere.

You mentioned soldering cells, which implies diy'ing your own. Unless it is strictly for fun, just know that NONE of the cells you can obtain as a diy'er are the so-called "grade-a". They are rejects or scraps with faults. Some may even look good, but under test reveal micro-fractures and a number of other flaws you as a non-manufacturer aren't clued in on. Manufacturers actually get the good ones that pass. Many scammers on the market try to pass of free-cell garbage onto diy'ers.

In addition, diy'ing a panel by soldering cells means you are not finished. To do it right you need encapsulation to prevent moisture damage, and also anti-reflective glass for the top to trap and redirect stray off-angle rays back onto the cells themselves. This isn't usually something you find online.

There is a hobby nature to diy'ing your own panel, but in the end it is a one-off science project, not something to be taken seriously.

That has not been my experience with *quality* panels.Mounted on a surface they over heat and cook

In fact, just the opposite. I did a test with an older high-quality Sanyo panel laid flat across 115F concrete in the middle of summer with sun overhead. With a laser temp-probe, I watched it cook and drop it's output dramatically.

Laid next to it was a PowerFilm, also sitting on 115F concrete. This didn't even have the inch or so of spacing that the rigid Sanyo had with it's aluminum mounts.

It pulled full spec and showed no sign of loss of output to heat degradation.

Note that this was for testing, not a permanent mounting consideration!

I'm just saying there is garbage and there is good stuff. One thing for sure, poor engineering like using slip-apart SAE connectors, weak alligator clips and the usual junk for interconnects that come with flexible panels don't do very well. I tend to chop off the junk connections and use Powerpoles, but that's me.

I need the Semi flex cells loose for manual solder as I am fitting them into a complex pattern on a home designed, home built experimental vessel. The flex cells sold on Aliexpress for sure look suspicious. The one I am looking to buy is called Maxeon c60, and is supposedly of a higher quality grade than others. Perhaps I could start out with only a few, just to learn the market, and to test durability under different conditions. This is a project that I just started, and I plan to buy "regular" pv-panels beforehand for my off grid shed and shop setup.Yes, constant exposure to ultraviolet light makes the surrounding material, exposed wires and so forth degrade. Low-end flexible cells do likewise. Higher quality ones last longer.

The ones we can get a hold of are typically NOT meant to be a permanent solution. The tip here is that when you aren't actually using them, cover them up. Ie, if you are a weekend warrior, don't leave the panels exposed to the sun the rest of the week doing nothing - you'll get more life.

How they are actually made can be found elsewhere.

You mentioned soldering cells, which implies diy'ing your own. Unless it is strictly for fun, just know that NONE of the cells you can obtain as a diy'er are the so-called "grade-a". They are rejects or scraps with faults. Some may even look good, but under test reveal micro-fractures and a number of other flaws you as a non-manufacturer aren't clued in on. Manufacturers actually get the good ones that pass. Many scammers on the market try to pass of free-cell garbage onto diy'ers.

In addition, diy'ing a panel by soldering cells means you are not finished. To do it right you need encapsulation to prevent moisture damage, and also anti-reflective glass for the top to trap and redirect stray off-angle rays back onto the cells themselves. This isn't usually something you find online.

There is a hobby nature to diy'ing your own panel, but in the end it is a one-off science project, not something to be taken seriously.

Similar threads

- Replies

- 19

- Views

- 956

- Replies

- 6

- Views

- 543