JustPractical

New Member

- Joined

- Aug 31, 2021

- Messages

- 106

I've reached that point in the project where I'm second guessing everything and running out of money. I could use some help with the thinking part.

My ground mount array will be 4640w, 16x290w, Two banks of 4S2P feeding two separate PV inputs on a Growatt 12k. I plan to mount the disconnect on the array, and originally planned for it to also be the combiner – but now I’m seeing things that look like “plug combiners” that might work (I’m not familiar with them – saw them on Practical Prepper.net website). If I was using the disconnect as a combiner, it’s 8 wires turning into 4.

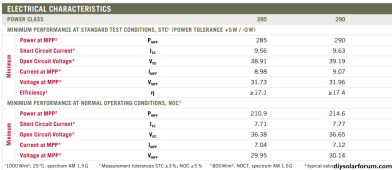

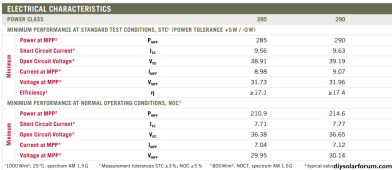

Panels are Q.PEAK 290's Voc=39, Isc=9.63 Imax=9.07. Each bank of 4S2P would then be a max of 157 volts and 19 amps per bank combined.

QUESTION #1: based on the spec sheet of the 290W panel (second column of the attached image) have I calculated these numbers properly?

Battery voltage will be 48V nominal. This is an off-grid system. The array, a ground mount, will be about 90 feet from the house, and then another 40 feet inside the house to the inverter.

Inverter info: Growatt 12kw Inverter - 2x60A 250V MPPT’s (Split phase 120/240) 100A Max Charging Current 7000W max per MPPT

QUESTION #2: I think I can run 12AWG THHN to each bank of the array (so a total of Four 12AWG conductors heading back from the array to the inverter). Yes? I keep trying to use “worst case numbers” for everything, but don’t want to oversize the wire. The wire will run in PVC conduit for most of its length (outside is buried conduit).

Have I missed something? Is there a cheaper or better way? Thanks in advance - this group has been super helpful.

My ground mount array will be 4640w, 16x290w, Two banks of 4S2P feeding two separate PV inputs on a Growatt 12k. I plan to mount the disconnect on the array, and originally planned for it to also be the combiner – but now I’m seeing things that look like “plug combiners” that might work (I’m not familiar with them – saw them on Practical Prepper.net website). If I was using the disconnect as a combiner, it’s 8 wires turning into 4.

Panels are Q.PEAK 290's Voc=39, Isc=9.63 Imax=9.07. Each bank of 4S2P would then be a max of 157 volts and 19 amps per bank combined.

QUESTION #1: based on the spec sheet of the 290W panel (second column of the attached image) have I calculated these numbers properly?

Battery voltage will be 48V nominal. This is an off-grid system. The array, a ground mount, will be about 90 feet from the house, and then another 40 feet inside the house to the inverter.

Inverter info: Growatt 12kw Inverter - 2x60A 250V MPPT’s (Split phase 120/240) 100A Max Charging Current 7000W max per MPPT

QUESTION #2: I think I can run 12AWG THHN to each bank of the array (so a total of Four 12AWG conductors heading back from the array to the inverter). Yes? I keep trying to use “worst case numbers” for everything, but don’t want to oversize the wire. The wire will run in PVC conduit for most of its length (outside is buried conduit).

Have I missed something? Is there a cheaper or better way? Thanks in advance - this group has been super helpful.