It's Lishen 272AH cells. 150A JBD BMS.What is the ah rating of each battery?

What exactly is a discrete fuse?

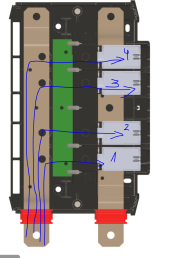

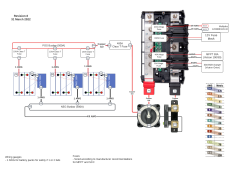

That's my current install.

I was a bit in a rush last summer. So I did a v1 with only 1 pack.

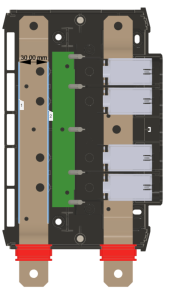

But I would like to use the AC inverter for bigger load and putting 4 packs in this space seemed complicated so went with 3 instead.