Depends. Cheapest part of off grid is most likely the panels, most expensive the batteries. Provided you have space and enough panels, one array SE and one SW give more usable power throughout the day and less dependence/wear on batteries.You're designing it wrong...I mounted east-west for offgrid, but now I realize that it would be best to just optimize for max solar production for the worst time of year for your area. For me that means steep slant for winter. You'll need batteries so your design has to be to fill up the batteries everyday. The east-west design stuff etc. is useful if you have certain time of use pricing on the grid that you are trying to offset.

Design for the cheapest max production (vertical mount could be cheaper...) during your worst week of the year.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Vertical mounted bi-facial panel question

- Thread starter TACOTIM

- Start date

I might have to redesign my biracial setup. I didn’t realize one got same power from backside. Interesting, was going to go with adjustable tilt, but now have to research just a vertical mount.When you have a vertical mounted Bifacial - East West - the "backside" changes depending on the time of the day.

When vertical mounting you take advantage of both sides. "additional" doesn't matter - because one side gets the sun in the first half of the day and the other side in the second half of the day.

View attachment 187767

View attachment 187768

Bifacial Solar Panels Give Increased Power Output Potential - Knowledge - DS New Energy

Bifacial Solar Panels Give Increased Power Output Potentialwww.dsneg.com

Brucey

Solar Wizard

The backside is still "weaker" than the front I believe. I'm guessing one would put the weak/rear side facing east so you get the longer afternoon hours on the prime/front side.I might have to redesign my biracial setup. I didn’t realize one got same power from backside. Interesting, was going to go with adjustable tilt, but now have to research just a vertical mount.

shadowmaker

Solar Addict

Not really as panel "backside" has usually less output in it. I have seen some claims up to 95-98% bifaciality though. Mine are only 70%. Also my array has 138 degree azimuth, so this time of year backside stays backside as we have only 5,5 hour of sun up here. Summer with 19 hours of sun is different.When you have a vertical mounted Bifacial - East West - the "backside" changes depending on the time of the day.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

That what I have seen on the test panels what we got here. It is really difficult to tell the difference on a MPPT if you look at front or back.I have seen some claims up to 95-98% bifaciality though.

They get slightly less on the back because the glass is deeper into the frame and causes some shadowing. Likely that would not happen on frameless panels.

The backside is still "weaker" than the front I believe.

Probably depends in the manufacturer - where they choose to run their wiring traces. If you have a good Bi-Facial panel - you have wiring traces on both sides in equal amount and thus the difference is insignificant.

for the money you save on a tilting system you can just add a few more panels and make up for difference in cheaper mounting cost.Interesting, was going to go with adjustable tilt, but now have to research just a vertical mount.

That is the whole promise of vertical solar - using marginal spaces - with low install cost.

Brucey

Solar Wizard

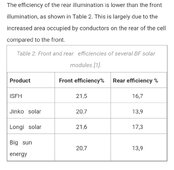

But based on your link, there can be a significant difference in efficiency between the front and back sides:That what I have seen on the test panels what we got here. It is really difficult to tell the difference on a MPPT if you look at front or back.

They get slightly less on the back because the glass is deeper into the frame and causes some shadowing. Likely that would not happen on frameless panels.

Probably depends in the manufacturer - where they choose to run their wiring traces. If you have a good Bi-Facial panel - you have wiring traces on both sides in equal amount and thus the difference is insignificant.

for the money you save on a tilting system you can just add a few more panels and make up for difference in cheaper mounting cost.

That is the whole promise of vertical solar - using marginal spaces - with low install cost.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

True at the point where that paper was published.But based on your link, there can be a significant difference in efficiency between the front and back sides:

View attachment 187788

Bifacial panels came a long way since 2018.

We are currently testing 2022 panels here at my University and they are much better on the rear.

I don't have the final results yet, we need at least 2 years of data to have somewhat unbiased results.

Some of the preliminary test we did was just put two identical panels side by side, one with the front into the sun and the other with the back.

The power curves look virtual identical. The rear is trailing, but the difference is small. A couple of watt hours each day.

Still, do your own research, various manufacturers and models may differ.

redalertdt

New Member

- Joined

- Feb 17, 2021

- Messages

- 58

Also almost any array designed to fill up for night time will be about miniumum 2x the actual load during the day so you can save some for night time. You may be able to slightly extend the hours covered, but not enough to make a big difference vs. optimal angle in my opinion.Depends. Cheapest part of off grid is most likely the panels, most expensive the batteries. Provided you have space and enough panels, one array SE and one SW give more usable power throughout the day and less dependence/wear on batteries.

If you are way over on panels might make sense to point different directions. But if you are so far over on panels that you don't care at all on the worst week of the year (no generator usage and no concern on generation side) then you probably have too many panels? Then again too many is probably just about right ;-)

Brucey

Solar Wizard

In my locale the zoning requires the following:True at the point where that paper was published.

Bifacial panels came a long way since 2018.

We are currently testing 2022 panels here at my University and they are much better on the rear.

I don't have the final results yet, we need at least 2 years of data to have somewhat unbiased results.

Some of the preliminary test we did was just put two identical panels side by side, one with the front into the sun and the other with the back.

The power curves look virtual identical. The rear is trailing, but the difference is small. A couple of watt hours each day.

Still, do your own research, various manufacturers and models may differ.

Solar energy collection systems and other facilities shall be designed and located in order to prevent reflective glare toward any inhabited buildings on adjacent properties and roads.

Depending on surroundings this may affect placement of vertical panels.

shadowmaker

Solar Addict

My panels have anti-glare finishing on them and I have never noticed any glaring problem with them. That doesn't mean there wouldn't be any complaints if they were installed this way in some more crowded place.In my locale the zoning requires the following:

Solar energy collection systems and other facilities shall be designed and located in order to prevent reflective glare toward any inhabited buildings on adjacent properties and roads.

Depending on surroundings this may affect placement of vertical panels.

In June 2021 there was a news article about Longi achieving the best bifaciality factor of any panel. I believe this was related to commercially available panels, not laboratory achievements.True at the point where that paper was published.

Bifacial panels came a long way since 2018.

We are currently testing 2022 panels here at my University and they are much better on the rear.

I don't have the final results yet, we need at least 2 years of data to have somewhat unbiased results.

Some of the preliminary test we did was just put two identical panels side by side, one with the front into the sun and the other with the back.

The power curves look virtual identical. The rear is trailing, but the difference is small. A couple of watt hours each day.

Still, do your own research, various manufacturers and models may differ.

At that time, I had some professional calculations done. I anticipated the bifaciality factor would improve over time, so I selected a bifaciality factor of 83.5% for the calculation. This was a slightly better factor than what had been achieved by Longi or anyone to my knowledge.

The calculation aimed to symmetrically match the output of both sides of a vertical bifacial panel so that an optimally sized MPPT could be used. The calculation was done for the Summer solstice at 28.7 degrees south latitude.

This was the result:

The two sides of the fence will produce the same amount of power if the good side is oriented 315° from North, which happens to be exactly Northwest.

I don't know if latitude influenced the calculation, but presumably the higher the bifaciality factor the closer to true North the panels should be aligned.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

yes a reflective panel would be bad for performance, most all newer panels are pretty dull and almost matt black.My panels have anti-glare finishing on them and I have never noticed any glaring problem with them. That doesn't mean there wouldn't be any complaints if they were installed this way in some more crowded place.

The two sides of the fence will produce the same amount of power if the good side is oriented 315° from North, which happens to be exactly Northwest.

I don't know if latitude influenced the calculation, but presumably the higher the bifaciality factor the closer to true North the panels should be aligned.

That is very interesting calculation, I have to run that numbers. In our test setup we have them running north-south to true north.

Two MPPTs - one has it's panels "Upside" to the west the other to east.

Interesting side observation in Florida is - it gets cloudy and raining in the afternoon, subtropical climate.

So the array with the upside facing west is producing less overall. We have clear mornings till early afternoon.

Whatever results the study will bring - we already know that it will be primary applicable for climates like ours. In a dry climate - with most of the sunshine in the afternoon - you will likely see different results.

I would guess we are seeing at least that value, with commercial 2022 bifacial panels. No hard data yet, one year is just not enough to say anything with confidence.I anticipated the bifaciality factor would improve over time, so I selected a bifaciality factor of 83.5% for the calculation

I planned to parallel E & W sides through a single MPPT. Theoretically, they are working at different times of the day.Two MPPTs - one has it's panels "Upside" to the west the other to east.

KevinC_63559

New Member

Other threads have indicated optimal bifacial yields about 2/3rd of the energy per day as an optimally tilted south facing (for northern hemisphere) bifacial ground mounted system. Goals vary, but for many, its simply to charge their batteries, in which case the ground mounted tilted system apparently wins.

My biggest concern with bifacial fencing systems is the wiring cost. Secondary concerns come from having literally miles of barb wire fencing - weeds tend to grow at the bases of all fences which would become a shading problem with the typical 1 foot (or so) gap at the bottom. Since I raise cattle and own horses and goats, I'm also concerned about the livestock nibbling on the wiring. I've had horses break off car rear windshield wipers having "fun" exploring things. Besides the cost, vertical fencing with solar panels (at least on my farm) just does not seem practical. Still, a fascinating concept....

My biggest concern with bifacial fencing systems is the wiring cost. Secondary concerns come from having literally miles of barb wire fencing - weeds tend to grow at the bases of all fences which would become a shading problem with the typical 1 foot (or so) gap at the bottom. Since I raise cattle and own horses and goats, I'm also concerned about the livestock nibbling on the wiring. I've had horses break off car rear windshield wipers having "fun" exploring things. Besides the cost, vertical fencing with solar panels (at least on my farm) just does not seem practical. Still, a fascinating concept....

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

those are all valid concerns and since this a new application and tech shall be addressed.My biggest concern with bifacial fencing systems is the wiring cost. Secondary concerns come from having literally miles of barb wire fencing - weeds tend to grow at the bases of all fences which would become a shading problem with the typical 1 foot (or so) gap at the bottom. Since I raise cattle and own horses and goats, I'm also concerned about the livestock nibbling on the wiring. I've had horses break off car rear windshield wipers having "fun" exploring things. Besides the cost, vertical fencing with solar panels (at least on my farm) just does not seem practical.

Total racking cost should be cheaper, Wiring cost ? we don't know, Where do you put the inverters? Do you go directly to batteries ?

In some areas - you do not have the space to put a perfectly angled south mounted system. Then you have to make the decision, - no solar or solar which is not as efficient per panel. Which is just a cost decision. When installed panel prices are cheap enough and you are space constrained - total efficiency per doesn't matter as much.

I rather have a solar fence - then a privacy fence - which costs similar.

KevinC_63559

New Member

I'm not aware of any privacy fence that cost $100/ft. For large fences, like on a farm, our cost is closer to $0.10/ft (for electric fences) or $1 or two a foot for 5 strand barb wire - installed.those are all valid concerns and since this a new application and tech shall be addressed.

Total racking cost should be cheaper, Wiring cost ? we don't know, Where do you put the inverters? Do you go directly to batteries ?

In some areas - you do not have the space to put a perfectly angled south mounted system. Then you have to make the decision, - no solar or solar which is not as efficient per panel. Which is just a cost decision. When installed panel prices are cheap enough and you are space constrained - total efficiency per doesn't matter as much.

I rather have a solar fence - then a privacy fence - which costs similar.

Of course for the choice of vertical or nothing, vertical make sense.

Inverters go next to the batteries unless your just doing a grid-tied, battery free, installation.

Curious about quantities of MPPT charge controllers needed so lets run some math: Assuming 550W XXL panels to minimize mounting cost, lets use this panel as an example: nominal power of 412.5 watts, max open circuit voltage 50V. Calculated nominal amperage of 412.5/12 = 34 amps. OK, thats going to get clipped by the 13amp maximum power rating Presuming we want to minimize component lets use this MPPT controller: 100amp charge rate, 250V max open circuit voltage, 12/24/48V operations. Presuming we want to minimize wiring cost that gives us 48V operation, so each set of (4) panels in series passes with a max open circuit voltage of 200V. If we waste a bit of peak power, we could parallel (8) of these 48V serial panels into one MPPT controller for a total of (32) panels per controller.

These panels are 90 x 45 inches in size - presuming a horizontal 2 panel height design, plus a couple of inches for mounting hardware, and a 100 ft run would take 13 sets of panels (26 total panels). Hmmm, that doesn't work out great, goal is 32 panels, or at least something in a multiple of 4. So f**k it, lets make a section 123 feet long so we can maximize utilization of components. So, 17 mounting poles @, oh, $140 each plus tax, call it $150*17=$2618. Panels cost $290 each, plus shipping. So at least $300*32=$9600. MPPT controller seems to run around $600, so we are at something like $12,800 so far plus or minus perhaps 10-20%.

Now the tricky part - wiring. 48V @ 100 amps. Playing with numbers on this calculator would imply 2/0 copper wiring for 48V, 100amp, 100 foot run with a 3.25% voltage drop (shooting for 3% or less, which is close enough). 250 feet pushes it with 4/0 copper having a 5.11% drop (not great, not horrible). But lets assume you can place the charge controller within 100 feet of one end of the fence. Hmmm, can't do that though, because we have 123 feet of fencing interconnected already. So you could, I suppose, wire the fence with 2/0 copper with a 4% voltage loss, then wire to the controller with 4/0 copper for an additional 2% drop, or wire the entire 123+100=223 foot run with 4/0 copper for a 4.5% voltage drop. Switch that to Aluminum and your at a sickly 7.18% voltage drop and getting worse if you are more than 100 ft between the fence and the controller. So lets say 4/0 copper. Ballpark (here) that's $3727 per 500' roll, which can be cut in half with a bit left over. Actually not as bad as I thought.

Total cost for major components is therefore $12800+$3727=$16527. That's presuming your doing it yourself and have no labor charges, and is missing other mounting hardware and things I'm sure I've forgotten, but still its $134.36/ft. A wooden fence is going to cost about 1/10th of that, but will require maintenance every few years. Chain link fence would be somewhat similar (fencing is cheap, poles and top rails and tension bars, etc. not so much so). Big difference.

Oh, but you will be generating power! 32 panels at 13 amps ~= 5000va, say at an overestimated 90% system efficiency = 4500va. But because we are vertical, we can only hope for about 67% panel output, so 3000va for, what?, 4 hours a day. That's 12KWh/day, unrealistically 365 days a year, for 4380 KWh/year. At $0.15/KWh, that's $657/year in power savings on a $16527 investment, for a 4% return on equity, so a 25 year pay back, which is pretty much the design life of the system. YMMV. Tax credits may apply. Batteries not included. ...

Last edited:

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

why would you do that? You want to have the highest voltage possible going to the MPPT to avoid line losses. My inverter has max input voltage of 480V an I am intending to use most of it. So 8 x 50V Panels in seriesPresuming we want to minimize wiring cost that gives us 48V operation, so each set of (4) panels in series passes with a max open circuit voltage of 200V.

There are newer MPPTs with 600V input out there. If you are doing grid connect you can get 800V input MPPT inverters.

look into PVC privacy fencing. A 6x 8 panel is $140. Lets try compare compare similar maintenance free things.wooden fence is going to cost about 1/10th of that, but will require maintenance every few years. Chain link fence would be somewhat similar (fencing is cheap, poles and top rails and tension bars, etc. not so much so). Big difference.

535W Bi-facial Palette of 28 $6580 - $240 per panel.

535 Watt Heliene Solar Panels Bifacial *Pallet Qty Only* - 28 Pieces

Model # 132HC M10 SL Bifacial Watts 490W VOC 49.97V ISC 13.48A Cell Type 144 Half Cut Monocrystalline Panel Dimensions 89.72L x 44.65W x 1.38H" Spec Sheet DOWNLOAD

2x EG4 6000XP Inverter ( 4x 4000w MPPT) https://signaturesolar.com/eg4-6000xp-off-grid-inverter-split-phase/

Now the tricky part - wiring. 48V @ 100 amps. Playing with numbers on this calculator would imply 2/0 copper wiring for 48V, 100amp, 100 foot run with a 3.25% voltage drop (shooting for 3% or less, which is close enough). 250 feet pushes it with 4/0 copper having a 5.11% drop (not great, not horrible). But lets assume you can place the charge controller within 100 feet of one end of the fence. Hmmm, can't do that though, because we have 123 feet of fencing interconnected already. So you could, I suppose, wire the fence with 2/0 copper with a 4% voltage loss, then wire to the controller with 4/0 copper for an additional 2% drop, or wire the entire 123+100=223 foot run with 4/0 copper for a 4.5% voltage drop. Switch that to Aluminum and your at a sickly 7.18% voltage drop and getting worse if you are more than 100 ft between the fence and the controller. So lets say 4/0 copper. Ballpark (here) that's $3727 per 500' roll, which can be cut in half with a bit left over. Actually not as bad as I thought.

you should not do any of that- the MPPT is supposed to sit directly above the battery - less then 5 ft away.

You use thin AWG10 MC4 connector wires at a high voltage 400-600V - going to the MPPT then a very short run to the batteries. Those things are less then $1 per foot - so $500 for a 500ft spool.

You calculation is way off.That's 12KWh/day, unrealistically 365 days a year,

I am getting 4kWh per day out of TWO 460w panels averaged over the last 3 years.

Meaning = 2 kWh per 460w panel / day

32x 550w = 17,600W - lets de-rate that because vertical - to a 15KW system (easier math)

Depending on location you are looking at 20-25,000 kWh annual according to the solar atlas.

Lets double check that math with my 2kWh/day per 460W panel

2kWh x 32 Panels x 365 = 23,360 kWH and I got smaller panels. So you are likely closer to 25.000 kWh annual out of the 32 panels you are suggesting.

KevinC_63559

New Member

why would you do that? You want to have the highest voltage possible going to the MPPT to avoid line losses. My inverter has max input voltage of 480V an I am intending to use most of it. So 8 x 50V Panels in series

I just used the max voltage of the linked Victron charge controller, which was 245V operating conditions. Thus 200V passed that sanity check. Of course, we can pick all different types of parts and nick-pick every comment - what I used was just a sample and appeared to be one of Victron higher capacity ones. I did not do a comprehensive review of all available MPPT chargers.

Wouldn't 600V wire need to placed in conduit for safety reasons? Hit that with a shovel and you might be in for a bad surprise.

eXodus

Solar Addict

- Joined

- Jul 27, 2020

- Messages

- 1,482

Either you bury it in a conduit or your run the wire back alongside the fence panels middles. Yep cutting a 600V DC wire under load would create a nice arc and is very dangerous and potential fatal.Wouldn't 600V wire need to placed in conduit for safety reasons? Hit that with a shovel and you might be in for a bad surprise.

But that is the same if you got a regular ground or roof mount system.

sorry for my misguided ton in that message. Must have come over the wrong way - I have to apologize,we can pick all different types of parts and nick-pick every comment

Similar threads

- Replies

- 4

- Views

- 287

- Replies

- 8

- Views

- 508

- Replies

- 6

- Views

- 224

- Replies

- 29

- Views

- 3K