jameshowison

New Member

- Joined

- Jul 30, 2021

- Messages

- 184

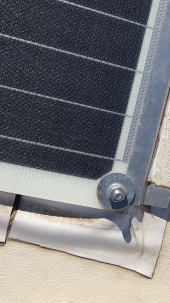

160w CIGS panels from Rich Solar. These were warranty replaced (I received a "store credit" and bought the 200w glass panels). So while I'm bitter about the whole thing at least Rich Solar did honor their warranty. My advice, though: if you have these panels remember to do this before the year is up. AFAICS Rich Solar is still selling these same panels ... they claim to have no info about manufacturing changes. I think they are betting that the "tape the edges" gets them past the *1 year* warranty period.

I thought people might like to know what it took to get these off the roof of our RV. They couldn't stay up there as already one of the full plastic cover sheets that delaminated came off somewhere, can't risk things flying off the RV and I wouldn't expect them to last without the plastic sheet. In case anyone is wondering, we installed these before the advice/requirement to tape the edges came out.

The butyl backing on the panels stuck very well to our smooth fiberglass roof. We were able to get a portion up with much sweat and small putty knives. We tried a few different things. No way to dissolve the butyl using adhesive removers (e.g., mineral spirits). Eventually we noticed that constant peeling pressure stretched the butyl and allowed us to release it with a knife. Did that by hand until we tired (like 6"!) So we rigged up a clamp from two pieces of wood screwed together with rope through holes at the ends. If you peel the connection end and get the clamp behind the connection that seems to work best. Then we used a ratchet clamp to pull a rope (through a turning block/snatch pulley, we swapped from the rachet clamp to the Masdem Rope Puller because that was easier and we had one https://www.maasdam.com/rope-pullers.html ). You want to set it up so that you don't have to move the clamp (which, unsurprisingly, is a pain because the butyl sticks to it ...)

Someone on the roof uses the knife to release the butyl, then calls for more pressure and so on until you hate the smell of butyl and curse the terrible product manufacturing that led to this debacle.

Thankfully the butyl left on the roof comes off surprisingly easily as it sticks to itself more than the roof. Still a massive time sink. I'd estimate it was 90 minutes of pulling and cutting to remove each panel, then an hour per panel of plucking sticky stuff off. Clean up with mineral spirits, and a razor scraper for some bits (especially the caulk we tried to use on the edges to stop the delamination ... that didn't work at all). Probably working in the hot sun helped the butyl stretch a bit.

Either the butyl or the heat stained the roof a smoker's yellow color. However that does seems to be lightening up in the strong sunlight, so it might not be horrendously ugly down the track.

Hope that gives others dealing with this product failure a few ideas of how to tackle this job.

I thought people might like to know what it took to get these off the roof of our RV. They couldn't stay up there as already one of the full plastic cover sheets that delaminated came off somewhere, can't risk things flying off the RV and I wouldn't expect them to last without the plastic sheet. In case anyone is wondering, we installed these before the advice/requirement to tape the edges came out.

The butyl backing on the panels stuck very well to our smooth fiberglass roof. We were able to get a portion up with much sweat and small putty knives. We tried a few different things. No way to dissolve the butyl using adhesive removers (e.g., mineral spirits). Eventually we noticed that constant peeling pressure stretched the butyl and allowed us to release it with a knife. Did that by hand until we tired (like 6"!) So we rigged up a clamp from two pieces of wood screwed together with rope through holes at the ends. If you peel the connection end and get the clamp behind the connection that seems to work best. Then we used a ratchet clamp to pull a rope (through a turning block/snatch pulley, we swapped from the rachet clamp to the Masdem Rope Puller because that was easier and we had one https://www.maasdam.com/rope-pullers.html ). You want to set it up so that you don't have to move the clamp (which, unsurprisingly, is a pain because the butyl sticks to it ...)

Someone on the roof uses the knife to release the butyl, then calls for more pressure and so on until you hate the smell of butyl and curse the terrible product manufacturing that led to this debacle.

Thankfully the butyl left on the roof comes off surprisingly easily as it sticks to itself more than the roof. Still a massive time sink. I'd estimate it was 90 minutes of pulling and cutting to remove each panel, then an hour per panel of plucking sticky stuff off. Clean up with mineral spirits, and a razor scraper for some bits (especially the caulk we tried to use on the edges to stop the delamination ... that didn't work at all). Probably working in the hot sun helped the butyl stretch a bit.

Either the butyl or the heat stained the roof a smoker's yellow color. However that does seems to be lightening up in the strong sunlight, so it might not be horrendously ugly down the track.

Hope that gives others dealing with this product failure a few ideas of how to tackle this job.