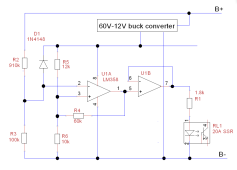

Bare with me here, I'm not a technician by any stretch of the imagination and I may well be wrong but, as far as I understand, if you directly connect a PV to a system with a battery connected, the system will not see PV voltage, rather battery voltage that will begin to rise as soc increases.

If that is the case, how would the relay ever see more than its trigger point of 14.4v ?

If that is the case, how would the relay ever see more than its trigger point of 14.4v ?