D

Deleted member 1888

Guest

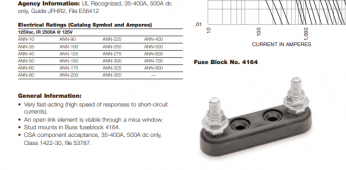

This is the 2nd time I have had a 300a ANL fuse blow at 150a (a cheap one and a name brand). Yester day I hit 150a and blew 1 fuse and the other looks burnt but still works. I'm starting to think that fuses just don't work at all maybe that's why homes no longer use fuse boxes and moved to breakers. I also noticed that my 2/0 wire gets hot on both sides of the fuse but not at any other point on the wires. Not even the wires on my shut have any heat at all.

Maybe I should replace all my fuses with DC breakers?

Maybe I should replace all my fuses with DC breakers?