Tell us please; What happens when it has a failed start ?? Does it automatically recover? Or do you need to intervene?

Depends on failure. You may collect some fault counts if you have some utility power glitches. If Start cap inside Easystart starts to go bad and drops in capacitance it can cause hard starts that immediately causes Easystart to 'pull the plug' due to excessive startup current. High capacitance start caps are electrolytic based. As their electrolyte dries out over time its capacitance decreases. This is same issue with hard start kits.

There is a three-minute timeout timer that prevents restart of compressor during the EasyStart short cycle hold off timer. Some air handlers with electronic controls with EEV expansion valve may throw a superheat error because compressor is not running,

Good thing is the Easystart power glitch shutdown with hold off timer will prevent a scroll compressor from reverse scroll run from a short (100 millisec or less) power glitch.

Other not so good thing is EasyStart can mask a bad Run capacitor. Unit will startup due to Easystart's start capacitor but when it releases after startup there will be no Run capacitor for compressor. Normally without Easystart, a Run cap failure will cause compressor to just grunt and pop its overcurrent breaker when it tries to start up. With Easystart and bad Run cap, you may not realize something is wrong. Compressor will only have Run winding current and will draw more power. With a bad Run capacitor, compressor will run hotter at higher power consumption, your electric bill will be higher, and run power factor is worse.

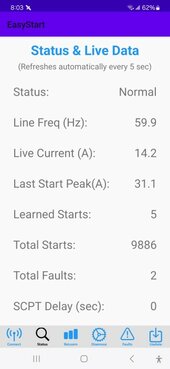

Another little secret is EasyStart with BT comm only measures current on compressor Run winding. It does not measure auxiliary (start) winding current. This causes EasyStart reported compressor run current to be about 20% lower than actual. Put a clamp on amp meter on compressor common wire if you would like to verify this. If you put clamp on meter to compressor Run winding it will be close to what Easystart is reporting. Auxiliary (start) winding current will be about 70% of Run winding current but is about 90 degrees out of phase so vector sum of the two currents is about 20% greater.

Total compressor common wire current = sqrt (run winding current ^2 + auxiliary winding current ^2) if Run cap is providing 90 degrees phase shift.

You should buy and keep a spare Easystart Start capacitor, Run capacitor, and contactor relay for your unit. Easystart's Start cap is easy to change, just lugs to disconnect from cap and some new tie-wraps to secure replacement start cap. Retrain EasyStart unit if you change either Start or Run caps.