Hi ,

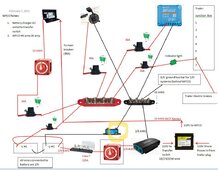

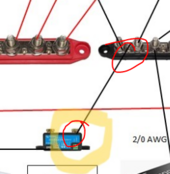

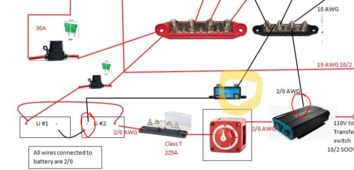

I recently installed 2 x 100 Lithium battery's and an 2000 inverter. I used 2/0 AWG wiring.

While running the 900W microwave, I checked my wiring and some seemed a bit warm...not hot.

I want to check all my connections. Besides correct torque values, is there any other good practices to do at connection points.

Thank you

I recently installed 2 x 100 Lithium battery's and an 2000 inverter. I used 2/0 AWG wiring.

While running the 900W microwave, I checked my wiring and some seemed a bit warm...not hot.

I want to check all my connections. Besides correct torque values, is there any other good practices to do at connection points.

Thank you