Steve_Rutland

New Member

- Joined

- Dec 4, 2022

- Messages

- 28

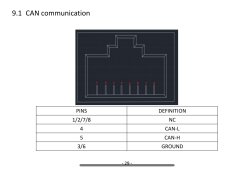

Righty guys, getting nowhere fast. Back onto comms lead making. Looking at the resources, Seplos use

CAN-L on pin 4

CAN-H on pin 5

GROUND 3/6

RS485-B on pin 1/8

RS485-A on pin 2/7

GROUND 3

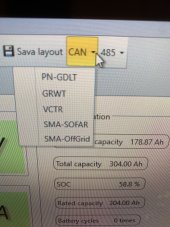

Soooo, my LuxPower tek3600ACS has a RS485/CAN port, do i make a lead using both or just stick to one form of communication and if so, which is best, CAN or RS485?

Also, where it states 2 numbers on a pin ie 1/8, do i have to connect into both or just choose 1 pin?

I have the latest 200A BMS which i think supports both formats.

Last but not least, if i am required to make a dual comms lead, which plug would i put it into on the BMS?

CAN-L on pin 4

CAN-H on pin 5

GROUND 3/6

RS485-B on pin 1/8

RS485-A on pin 2/7

GROUND 3

Soooo, my LuxPower tek3600ACS has a RS485/CAN port, do i make a lead using both or just stick to one form of communication and if so, which is best, CAN or RS485?

Also, where it states 2 numbers on a pin ie 1/8, do i have to connect into both or just choose 1 pin?

I have the latest 200A BMS which i think supports both formats.

Last but not least, if i am required to make a dual comms lead, which plug would i put it into on the BMS?