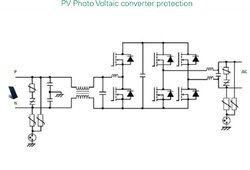

Haven't seen this posted elsewhere. The inverter I ordered (Growatt MIN11400) says it has class 2 DC surge protection. My solar panels will be about 100 feet from the inverter on the roof of a barn. Should I add another supressor such as the Midnite Solar? Midnite Solar says to install their supressor at the input to the inverter. If I add a surge supressor, should it be near the array, or at the inverter? I would expect having two supressors in parallel would increase the protection?

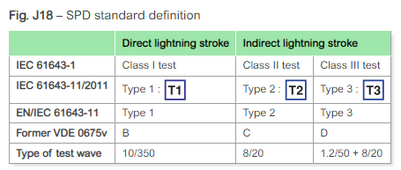

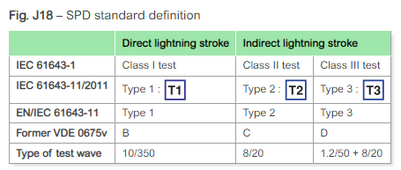

Midnite Solar's website says their 600 volt version can handle currents with a 8/20us wave form. As far as I can tell, a class 2 supressor is the same, however I can't find how much energy the Growatt can handle vs the 2160 joules of the Midnite solar. Any thoughts?

Midnite Solar's website says their 600 volt version can handle currents with a 8/20us wave form. As far as I can tell, a class 2 supressor is the same, however I can't find how much energy the Growatt can handle vs the 2160 joules of the Midnite solar. Any thoughts?