MartyByrde

Off-Grid Innovator

Can you clarify the positioning a little more?Couldn't resist looking into the manual and I agree with the note from @Lt.Dan about the terminals.

The manual is, imho, wrong here. To me, the busbars should make direct contact to the terminals busbar, and the current should NOT be passing the (fixed) nut. That nut/thread is only to secure the bolt.

That busbar should be mounted exactly the other way, so the bar from the fuse makes direct contact with the busbar towards the terminals.

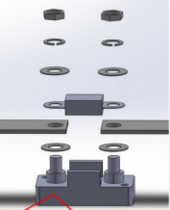

Got it thanksNOT as in this image where the supporting nut is part of the circuit.

View attachment 193505View attachment 193507

I found a picture in another Apexium thread:

This is how it should be in my opinion, not as in the manual

View attachment 193510

As for the washers: Remove washer C. So the fuse is in direct contact with the busbar. The washers on both sides should 'sandwich' the busbar/fuse, but not be in beween.

Will a heat laser work?Current is passing the main circuit, busbar on busbar / terminal / fuse. Bolts/nuts/washers are to secure it in place. If there is no other way, use suitable conductive materials. Regular (steel/rvs) washers eg aren't.

When in doubt (And I personally always do on high current installs), run it for 15-30min and check with a flir camera. Any bad connection/resistance will show up very clearly.