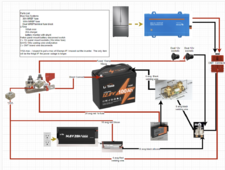

scc $13

mppt style

battery options with low temp cutoff

$33 12ah roypow (153wh)

$50 18ah roypow (230wh)

$90 30ah roypow (384wh)

fusing $50

dual terminal mrbf block (connections for battery, inverter, and panel positive lines)

mrbf 30A (scc to terminal block positive)

mrbf 100A (inverter to terminal block positive)

80A on off switch $8 (connect both the inverter and scc negatives to this switch mounted to the battery negative terminal)

48v 275A 1-2 bank kill switch $12 (connections for battery, inverter, and panel negative lines)

pure sine inverter options $30-$50 (least expensive pure sine inverters on 'zon.)

400w continual $50

300W continual $40

500w continual $32

All that is needed is a 50-200w of panel and the wiring. $50-100

I would use10-12 awg for all wiring but inverter which is 8awg.

Use 8wag for all wiring and 6awg for the line going to inverter (thanks @robbob2112)

*note with a 20a scc this system can theoretically produce up to 800w at 40A between battery and scc input if inverter wires (6awg) and fuse (100a) are sized correctly and given enough panel input. The intent of this system is not an 800w draw but rather powering loads less than 100w that may surge up to 100w like my danby or midea. at a 10Wh average draw and 100w surge each I could power both units from this system at the same time. 20w (2A) continual 200w (16A) surge

critique?

I know it's the cheapest of the cheap. Think it would work for the intended purpose or just make a nice ball of flames?

mppt style

battery options with low temp cutoff

$33 12ah roypow (153wh)

$50 18ah roypow (230wh)

$90 30ah roypow (384wh)

fusing $50

dual terminal mrbf block (connections for battery, inverter, and panel positive lines)

mrbf 30A (scc to terminal block positive)

mrbf 100A (inverter to terminal block positive)

48v 275A 1-2 bank kill switch $12 (connections for battery, inverter, and panel negative lines)

pure sine inverter options $30-$50 (least expensive pure sine inverters on 'zon.)

400w continual $50

300W continual $40

500w continual $32

All that is needed is a 50-200w of panel and the wiring. $50-100

I would use

Use 8wag for all wiring and 6awg for the line going to inverter (thanks @robbob2112)

*note with a 20a scc this system can theoretically produce up to 800w at 40A between battery and scc input if inverter wires (6awg) and fuse (100a) are sized correctly and given enough panel input. The intent of this system is not an 800w draw but rather powering loads less than 100w that may surge up to 100w like my danby or midea. at a 10Wh average draw and 100w surge each I could power both units from this system at the same time. 20w (2A) continual 200w (16A) surge

critique?

I know it's the cheapest of the cheap. Think it would work for the intended purpose or just make a nice ball of flames?

Last edited: