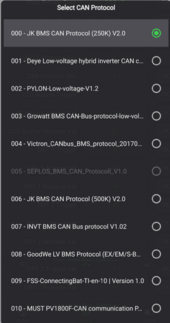

And the results are in... Sadly there is no change in the charging performance with paired with an EG4/Luxpower 6000XP.

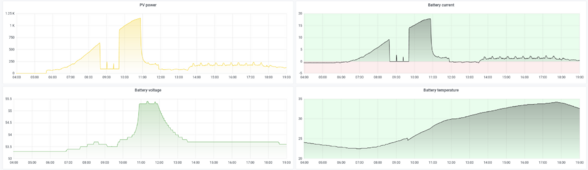

Here is the screen capture from Solar Assistant showing the charge behavior this morning.

I didn't bother including the battery SOC graph, it was at 99% this morning and hit 100% at ~8am when the charging cut out.

At 5:45am the sun rose and the PV array began generating power

At 6:15am there was enough solar power to overcome the standby power consumption and charging began.

Charge current begins to increase, and with it battery voltage

At 8:30am the battery SoC hit 100% and the EG4/Luxpower charge logic shut down the charger.

NOTE: The battery voltage is only at 53.7V, a far cry from my target RCV voltage of 55.2! The sun is shining and my batteries are not full, but no charging is happening.

The characteristic chirping behavior of the EG$/Luxpower is clearly visible for the next hour during this period. The charger does kick on for a few minutes but not nearly enough to actually charge the battery

At 9:45am I re-connected my ghost battery and charging resumes as expected. Due to drift in the coulomb counting the battery needs another hour or so of charging to get up to RCV. I will make a followup post after I confirm that the charge controller is still working correctly (battery gets to RCV, then holds for 1 hour, and then drops to RFV) with the ghost battery connected on the new firmware.

For more information about the ghost battery, see the previous posts: it is a JKBMS based battery at 0% SOC which is connected ONLY via RS485 parallel coms (the DC connections are not connected) to trick the JKBMS master into reporting 99% SOC instead of 100 while the charge controller is active.

Overall it is a bummer that this issue is still present. Really I think that JK is in the right here and it is EG4/Luxpower who need to respect the pylontech charge request flag, but support from EG4 has been worse than the support from JK which is really saying something.

Here is the screen capture from Solar Assistant showing the charge behavior this morning.

I didn't bother including the battery SOC graph, it was at 99% this morning and hit 100% at ~8am when the charging cut out.

At 5:45am the sun rose and the PV array began generating power

At 6:15am there was enough solar power to overcome the standby power consumption and charging began.

Charge current begins to increase, and with it battery voltage

At 8:30am the battery SoC hit 100% and the EG4/Luxpower charge logic shut down the charger.

NOTE: The battery voltage is only at 53.7V, a far cry from my target RCV voltage of 55.2! The sun is shining and my batteries are not full, but no charging is happening.

The characteristic chirping behavior of the EG$/Luxpower is clearly visible for the next hour during this period. The charger does kick on for a few minutes but not nearly enough to actually charge the battery

At 9:45am I re-connected my ghost battery and charging resumes as expected. Due to drift in the coulomb counting the battery needs another hour or so of charging to get up to RCV. I will make a followup post after I confirm that the charge controller is still working correctly (battery gets to RCV, then holds for 1 hour, and then drops to RFV) with the ghost battery connected on the new firmware.

For more information about the ghost battery, see the previous posts: it is a JKBMS based battery at 0% SOC which is connected ONLY via RS485 parallel coms (the DC connections are not connected) to trick the JKBMS master into reporting 99% SOC instead of 100 while the charge controller is active.

Overall it is a bummer that this issue is still present. Really I think that JK is in the right here and it is EG4/Luxpower who need to respect the pylontech charge request flag, but support from EG4 has been worse than the support from JK which is really saying something.