So I'm trying to charge 12 cells in series.

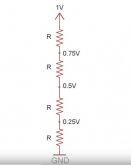

I recently installed a Chargery BMS which lets me know each cells voltage. It seems that the cells starting from the positive end of series decrease in voltage almost in a straight downward line so cell 1 is 2.8 volts cell 2 is 2.75 volts cell 3 2.7 volts on down to 2 volts for cell 12. These numbers are not exact but hopefully you get the Idea. If the cells were randomly different then I would just assume the internal resistance is off but since it is linear I'm wondering if it's something to do with the connectors between batteries? Anybody have any Ideas?

I recently installed a Chargery BMS which lets me know each cells voltage. It seems that the cells starting from the positive end of series decrease in voltage almost in a straight downward line so cell 1 is 2.8 volts cell 2 is 2.75 volts cell 3 2.7 volts on down to 2 volts for cell 12. These numbers are not exact but hopefully you get the Idea. If the cells were randomly different then I would just assume the internal resistance is off but since it is linear I'm wondering if it's something to do with the connectors between batteries? Anybody have any Ideas?