Hello everyone. Have a question and I hope to get some help. I am building a solar tracker. I have the panels mounted. I am using 18v, 7w small panels to activate the motor to move the panels. Here is my question. I am going to use a dewalt 20v battery to move the panels back to the starting point for the next morning. Will the battery backfeed to the panels?. Will the battery damage panels?. Should I put a couple diodes between the battery and the panels?. Any help would be greatly appreciated.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a solar tracker. Need some help

- Thread starter 585jim0

- Start date

6

629658

Guest

You can add panels cheaper and it will fail mechanically at some point.

pollenface

Solar Addict

Yes it will backfeed the panel unless you have a blocking diode.

I personally would use a 3rd panel in parallel with the eastern panel to move it back to the starting position in the morning (I've never done this, just thought about it)

I personally would use a 3rd panel in parallel with the eastern panel to move it back to the starting position in the morning (I've never done this, just thought about it)

Last edited:

Sverige

A Brit in Sweden

An alternative, cheaper way is to use limit switches to limit the westwards travel to that which allows the east facing panel to catch enough sun in the morning to bring the array back around. It doesn’t matter if this happens slowly because there’s an oblique angle - it just needs to happen. You don’t need the array fully perpendicular to the setting sun, after all, so a limit switch there isn’t costing much at all.

An easy way to implement a limit switch is a mercury tilt switch in the circuit between motor and tracker panel, then just arrange the mechanics so the tilt switch is attached to a member which changes angle as the array motors around.

The popcorn icon in post 2 refers to the fact you’ll likely have plenty of people wanting to talk you out of the idea, but I reckon you should go for it and hope you’ll start a build thread on here.

ps.. if you do go with your battery idea, maybe a 20V battery is over the top? Assuming you have your two small east / west panels wired in opposition to one another, the motor only ever sees the difference voltage between them - a lot less than 20V.

An easy way to implement a limit switch is a mercury tilt switch in the circuit between motor and tracker panel, then just arrange the mechanics so the tilt switch is attached to a member which changes angle as the array motors around.

The popcorn icon in post 2 refers to the fact you’ll likely have plenty of people wanting to talk you out of the idea, but I reckon you should go for it and hope you’ll start a build thread on here.

ps.. if you do go with your battery idea, maybe a 20V battery is over the top? Assuming you have your two small east / west panels wired in opposition to one another, the motor only ever sees the difference voltage between them - a lot less than 20V.

Last edited:

Thanks for the info.. I was thinking of limit switches. The reason I was gonna use a dewalt battery, I have a bunch of them. The small panels I am using have a 18 v 7 watt out put. I could use a 6v battery and use limit switches to cut out the panels and jump to battery and re-engage when it goes back to the start.. Its gonna be a few days before I get back at it.. I'll keep ya postedAn alternative, cheaper way is to use limit switches to limit the westwards travel to that which allows the east facing panel to catch enough sun in the morning to bring the array back around. It doesn’t matter if this happens slowly because there’s an oblique angle - it just needs to happen. You don’t need the array fully perpendicular to the setting sun, after all, so a limit switch there isn’t costing much at all.

An easy way to implement a limit switch is a mercury tilt switch in the circuit between motor and tracker panel, then just arrange the mechanics so the tilt switch is attached to a member which changes angle as the array motors around.

The popcorn icon in post 2 refers to the fact you’ll likely have plenty of people wanting to talk you out of the idea, but I reckon you should go for it and hope you’ll start a build thread on here.

ps.. if you do go with your battery idea, maybe a 20V battery is over the top? Assuming you have your two small east / west panels wired in opposition to one another, the motor only ever sees the difference voltage between them - a lot less than 20V.

AmyG

New Member

Keep in mind that DeWalt batteries don't have a low voltage cutoff - it's in the tool - so you'd need to either have a low voltage disconnect or keep an eye on the voltage and swap them out as needed. Sounds like your use case won't use much current, but you don't want to forget and kill one by letting it get too low. I believe they are 5S packs of 18650-type cells so I use a 16V cutoff to have a good safety margin and because the voltage drops off pretty quickly after that.

What size of diode should I use?. And I like the idea of a 3rd panelYes it will backfeed the panel unless you have a blocking diode.

I personally would use a 3rd panel in parallel with the eastern panel to move it back to the starting position in the morning (I've never done this, just thought about it)

It won't be used as a full time power supply.. Mostly weekends ot long weekends for out at my campsiteKeep in mind that DeWalt batteries don't have a low voltage cutoff - it's in the tool - so you'd need to either have a low voltage disconnect or keep an eye on the voltage and swap them out as needed. Sounds like your use case won't use much current, but you don't want to forget and kill one by letting it get too low. I believe they are 5S packs of 18650-type cells so I use a 16V cutoff to have a good safety margin and because the voltage drops off pretty quickly after that.

pollenface

Solar Addict

at least 2x the isc of the little solar panels I think, put the white stripe towards the negative side.What size of diode should I use?. And I like the idea of a 3rd panel

Thank you for the info..Everyone has giving atolt of great info and alot to think aboutat least 2x the isc of the little solar panels I think, put the white stripe towards the negative side.

TomC4306

Solar Obsessive

The way I am going to power my tracker is with a pair of panels mounted back to back at a steep angle to one another and short circuit wired to the motor in the linear actuator. Panel 1 + to panel 2 -. And vice versa. Each of these connected to either side of the motor.

It works well on the bench. Still sourcing the spinny parts for the array. Will build this spring

It works well on the bench. Still sourcing the spinny parts for the array. Will build this spring

Sverige

A Brit in Sweden

will be very interesting to see a build thread ?The way I am going to power my tracker is with a pair of panels mounted back to back at a steep angle to one another and short circuit wired to the motor in the linear actuator. Panel 1 + to panel 2 -. And vice versa. Each of these connected to either side of the motor.

It works well on the bench. Still sourcing the spinny parts for the array. Will build this spring

Warpspeed

Solar Wizard

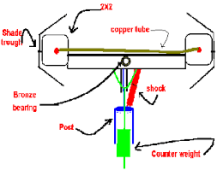

The simplest way to build a mechanical tracker is to use gravity to tilt the panels.

This can be done by fitting a couple of half full propane tanks to opposite edges, on either side of the pivot point.

The two tanks are interconnected with a pipe that allows the free flow of gas between tanks.

The tanks can be shaded in such a way, that when your panels are facing directly towards the sun, an equal amount of solar heat warms up both tanks equally.

As the sun moves, one tank progressively receives more shading than the other, the propane boils away from the warmer tank, and condenses in the cooler tank, thus shifting the weight of liquid propane towards the shaded side.

At sunrise one tank receives full direct sun, the other full shade, and the whole thing then tilts towards the sun.

It will then follow the sun throughout the day.

Being finely balanced, it will tend to flap around in the wind, but the way to fix that is to fit a pair of hydraulic car shock absorbers.

That will allow free tracking movement, as long as it is very slow.

Its the simplest possible system, very little to go wrong, and it will not be effected by freezing or very wet conditions.

Its easiest to start out during installation with one tank completely full, and the other completely empty. How many pounds of propane will give you a bit of an idea of the forces involved. But as the tanks will be located quite far apart, it will not take very much force to reliably tilt the whole thing.

This is a sketch I found on the internet, that illustrates the general idea :

This can be done by fitting a couple of half full propane tanks to opposite edges, on either side of the pivot point.

The two tanks are interconnected with a pipe that allows the free flow of gas between tanks.

The tanks can be shaded in such a way, that when your panels are facing directly towards the sun, an equal amount of solar heat warms up both tanks equally.

As the sun moves, one tank progressively receives more shading than the other, the propane boils away from the warmer tank, and condenses in the cooler tank, thus shifting the weight of liquid propane towards the shaded side.

At sunrise one tank receives full direct sun, the other full shade, and the whole thing then tilts towards the sun.

It will then follow the sun throughout the day.

Being finely balanced, it will tend to flap around in the wind, but the way to fix that is to fit a pair of hydraulic car shock absorbers.

That will allow free tracking movement, as long as it is very slow.

Its the simplest possible system, very little to go wrong, and it will not be effected by freezing or very wet conditions.

Its easiest to start out during installation with one tank completely full, and the other completely empty. How many pounds of propane will give you a bit of an idea of the forces involved. But as the tanks will be located quite far apart, it will not take very much force to reliably tilt the whole thing.

This is a sketch I found on the internet, that illustrates the general idea :

Attachments

Last edited:

curiouscarbon

Science Penguin

- Joined

- Jun 29, 2020

- Messages

- 3,027

something like this?The way I am going to power my tracker is with a pair of panels mounted back to back at a steep angle to one another and short circuit wired to the motor in the linear actuator. Panel 1 + to panel 2 -. And vice versa. Each of these connected to either side of the motor.

It works well on the bench. Still sourcing the spinny parts for the array. Will build this spring

Just remember a solar tracker mount should only be implemented as a last resort or if there is some extreme circumstances limiting space. A mechanical tracker will always be less reliable then "simply" having more than one fixed array pointing in different directions.

TomC4306

Solar Obsessive

Just remember a solar tracker mount should only be implemented as a last resort or if there is some extreme circumstances limiting space. A mechanical tracker will always be less reliable then "simply" having more than one fixed array pointing in different directions.

Like this?

It is the six leaning against the fence that I will use on the tracker. The tracker is something I've always wanted to do just to do.

Phase 3a in my solar panel iterations.

TomC4306

Solar Obsessive

Yes, mounted to a bracket above the array it's driving.something like this?

Driving an 18-in throw linear actuator mounted to the post and the table.

Also probably add a 'shadow caster'.

A piece of thin sheet material between and extending above the 2 panels. I think this might help improve the 'resolution' of the motion. A bit less herky jerky.

Similar threads

- Replies

- 64

- Views

- 4K

- Replies

- 11

- Views

- 652

- Replies

- 24

- Views

- 483

- Replies

- 2

- Views

- 250