You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Solar Tracker Design

- Thread starter 400bird

- Start date

400bird

Solar Wizard

Yes, thank you. Not the point here.

See post #1

I hope no one follows in my stupid steps and solar trackers are banned from history.

See post #1

I want to start by saying that I realize I will never recoup the money spent on this tracker. I don't need any reminders.

Electronics and solar are my hobby. The tracker was the 11 year old's idea and he wants to help!

I hope no one follows in my stupid steps and solar trackers are banned from history.

OffGridForGood

Catch, make or grow everything you can.

Actually, I was inspired to try out a similar project with my grandson next summer!Yes, thank you. Not the point here.

See post #1

I hope no one follows in my stupid steps and solar trackers are banned from history.

I think it is a great learning experience - and involves many different skills he could learn along the way: earthwork, concrete, metal working, geometry, electricity, electonics...great project to do together with an 11-year-old.

400bird

Solar Wizard

Thanks, we had a blast!Actually, I was inspired to try out a similar project with my grandson next summer!

I think it is a great learning experience - and involves many different skills he could learn along the way: earthwork, concrete, metal working, geometry, electricity, electonics...great project to do together with an 11-year-old.

He got to do some CAD work in Fusion 360 too

The engineering and hands on in so many different fields is good experience for him.

Oh, and plumbing, we threw a sprinkler pipe in the trench for a couple plants that needed water and happened to be on the same path.

400bird

Solar Wizard

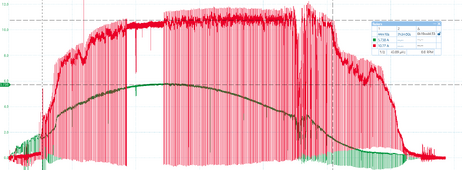

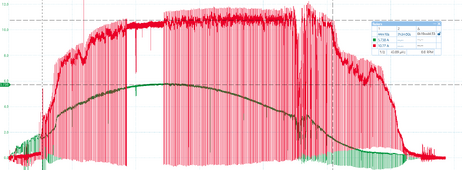

I've been trying since solstice to get a good sunny day and an available laptop to set up the oscilloscope to compare the two arrays.

Today was that day!

I have two identical arrays of 480 watt Q cell bifacial panels. Both are 2 in series paralleled into the same Midnite Classic 150 charge controller.

I am out of south facing roof, so I have 1 pair facing due east on my 4/12 roof (about 20°) (green trace)

The second pair is on the solar tracker (red trace)

The vertical lines every minute are the tracking doing a sweep. I turned the tracker from "PV" to "dynamic" for about 50 minutes while I looked up the options in the Midnite manual. PV is recommended and they don't detail dynamic very much. You can see the sweeps stop while in "dynamic" mode.

Green is roof mounted, facing due east 20° pitch

Red is dual axis tracker.

The vertical cursors mark when a hard shadow clears in the morning and when a soft shadow starts onto the panels in the evening. I probably lost an hour of good production due to that trampoline net.

A few clouds rolled through about an hour before that causing the drop and spike, otherwise it was sunny all day.

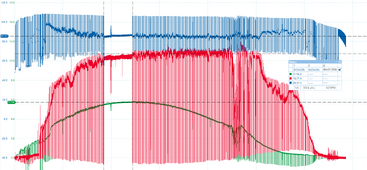

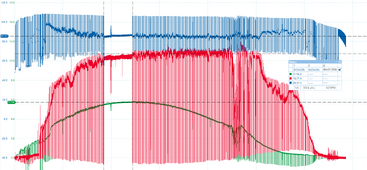

Here is the same graph plus voltage in blue

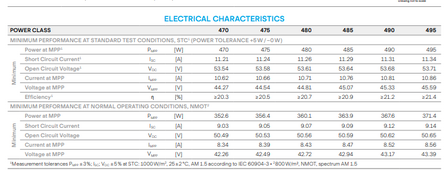

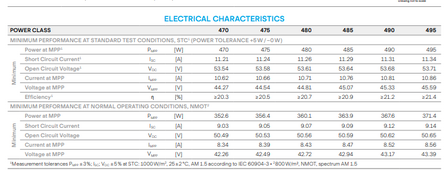

Panel specs:

The tracker mounted panels outperformed the IMP both STC and NOTC.

The east facing panels peaked at about 50% of IMP.

However voltage was below VMP (50.56 x 2) nearly all day. I don't know what to make of that.

This says to me the tracker is performing well. I'd probably need 4-6 more flat mounted panels (which I might not have room for even using both east and west roof faces)

I'll try and do this again in the spring or summer to see how the two arrays perform with more sun.

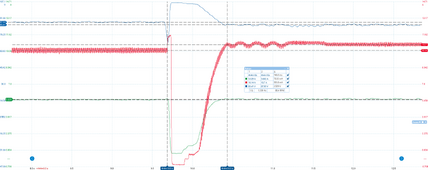

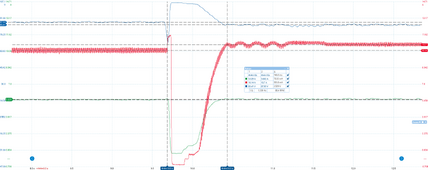

Oh, and for those curious, here's a tracking cycle with some markers:

Today was that day!

I have two identical arrays of 480 watt Q cell bifacial panels. Both are 2 in series paralleled into the same Midnite Classic 150 charge controller.

I am out of south facing roof, so I have 1 pair facing due east on my 4/12 roof (about 20°) (green trace)

The second pair is on the solar tracker (red trace)

The vertical lines every minute are the tracking doing a sweep. I turned the tracker from "PV" to "dynamic" for about 50 minutes while I looked up the options in the Midnite manual. PV is recommended and they don't detail dynamic very much. You can see the sweeps stop while in "dynamic" mode.

Green is roof mounted, facing due east 20° pitch

Red is dual axis tracker.

The vertical cursors mark when a hard shadow clears in the morning and when a soft shadow starts onto the panels in the evening. I probably lost an hour of good production due to that trampoline net.

A few clouds rolled through about an hour before that causing the drop and spike, otherwise it was sunny all day.

Here is the same graph plus voltage in blue

Panel specs:

The tracker mounted panels outperformed the IMP both STC and NOTC.

The east facing panels peaked at about 50% of IMP.

However voltage was below VMP (50.56 x 2) nearly all day. I don't know what to make of that.

This says to me the tracker is performing well. I'd probably need 4-6 more flat mounted panels (which I might not have room for even using both east and west roof faces)

I'll try and do this again in the spring or summer to see how the two arrays perform with more sun.

Oh, and for those curious, here's a tracking cycle with some markers:

Mr onetwo

New Member

The link you put in post #15 is kind of useless.Could you please give us a little more info about that drive and exactly how you went about purchasing it from China. It looks like a #3 size but there are many versions and manufacturers.A little clarification would be appreciated since we know yours works. Many thanks

Attachments

400bird

Solar Wizard

Good point, it seems most links to Alibaba are useless.

I took a risk and ordered on Alibaba: Xuzhou Helin Slewing Bering Co, Ltd

I tried my best to purchase something made anywhere else and couldn't find anything in this size.

Yes, it is a size 3 with 24 vdc motors and integrated hall sensors.

Here's the link, but it's typical the garbage Alibaba link:

I took a risk and ordered on Alibaba: Xuzhou Helin Slewing Bering Co, Ltd

I tried my best to purchase something made anywhere else and couldn't find anything in this size.

Yes, it is a size 3 with 24 vdc motors and integrated hall sensors.

Here's the link, but it's typical the garbage Alibaba link:

High Quality Solar Tracking Slewing Drive Worm Gear With Dual Axis - Buy Slewing Drive,Dual Axis Worm Gear Solar Tracker Slewing Drive,Truck Crane Slewing Drive Product on Alibaba.com

High Quality Solar Tracking Slewing Drive Worm Gear With Dual Axis - Buy Slewing Drive,Dual Axis Worm Gear Solar Tracker Slewing Drive,Truck Crane Slewing Drive Product on Alibaba.com

www.alibaba.com

Mr onetwo

New Member

Thanks...at least we know of one case where the product works. How long did it take to receive the drive after you paid for it? Also, could you please post up some photos showing the back side and slew drive details.

Last edited:

400bird

Solar Wizard

I told them to ship it the cheapest way possible. Took about 45 days. I'll try to get some shots from the back side tomorrow, it's too dark for good pictures right now.

400bird

Solar Wizard

Mr onetwo

New Member

freakin' awesome dude!

Mr onetwo

New Member

Mr onetwo

New Member

I don't think I can buy the steel for such a thing with out the slew drive or electronics for the price I was quoted.

OffGridForGood

Catch, make or grow everything you can.

Would that drive be sufficient for more PV, ie is it over-sized for just the two panels?Here's a couple pics, let me know if you wanted anything specific.View attachment 191744

View attachment 191745

400bird

Solar Wizard

I'm pretty sure it's oversized for 4 square meters of panels, but I couldn't find any don't have the skills to calculate the loads on the tracker. Plus, that was the size we wanted to build and the smallest slew drive available.

I consider designs like you propose, however that increases the distance (lever arm) and thus twisting force on the the slew drive is increased.

Twisting as in the wind blowing on the entire array, this force:

Also, yeah, I spent about as much in steel and aluminum as I did on the slew drive and electronics.

I consider designs like you propose, however that increases the distance (lever arm) and thus twisting force on the the slew drive is increased.

Twisting as in the wind blowing on the entire array, this force:

Also, yeah, I spent about as much in steel and aluminum as I did on the slew drive and electronics.

Mr onetwo

New Member

I'll bet it could do 5 panels without a problem. When I built the overhead crane in my shop I simply went to a bunch of websites until I found one with the specs of what I wanted. I simply matched their engineering.Not so easy to find in the solar tracker field.Hard to make it strong and stiff but not too heavy. Did you get charged any duty or import fees on your slew drive?

OffGridForGood

Catch, make or grow everything you can.

I have used 3" inside of 3-1/2" steel Schedule 40 pipe (the OD of the 3" is 9-thou smaller than the ID of the 3-1/2") to make things that need to slide or turn, just add a grease fitting.

I ponder using the single axis slew to rotate the smaller pipe inside the larger. The overlap between the two pipes can be the full length of the lower section and any wind forces will not be transfered to the slew mechanism. A cap piece would keep out water and dirt.

I ponder using the single axis slew to rotate the smaller pipe inside the larger. The overlap between the two pipes can be the full length of the lower section and any wind forces will not be transfered to the slew mechanism. A cap piece would keep out water and dirt.

400bird

Solar Wizard

Most of my googles lead to companies wanting to sell me a tracker. If you find something, let me know.I'll bet it could do 5 panels without a problem. When I built the overhead crane in my shop I simply went to a bunch of websites until I found one with the specs of what I wanted. I simply matched their engineering.Not so easy to find in the solar tracker field.

Aluminum!Hard to make it strong and stiff but not too heavy.

It shipped DDP (?) or some similar acronym that means the quote includes everything to get it to my door. I'm sure duties, tariffs, import fees were involved and that I paid them, but those were included in my invoice from the vendor.Did you get charged any duty or import fees on your slew drive?

400bird

Solar Wizard

Good point, the slew drives so have a hole through the middle. Depending on the size, it may not pass a 3" pipe through the middle or 3" may be undersized, but I'm sure the same idea scales to larger and smaller sizes.I have used 3" inside of 3-1/2" steel Schedule 40 pipe (the OD of the 3" is 9-thou smaller than the ID of the 3-1/2") to make things that need to slide or turn, just add a grease fitting.

I ponder using the single axis slew to rotate the smaller pipe inside the larger. The overlap between the two pipes can be the full length of the lower section and any wind forces will not be transfered to the slew mechanism. A cap piece would keep out water and dirt.

Similar threads

- Replies

- 0

- Views

- 209

- Replies

- 20

- Views

- 2K