Murphyslaww

New Member

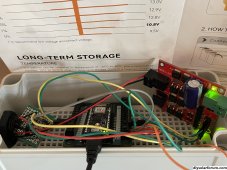

Been working through some issues, but I now seem to have a working, albeit too expensive, single-axis,linear actuator, Arduino controlled, panel lift.

Once I have some materials sorted it’ll be likely, around $100/panel, and then around $70-100 for the tracker electronics, which will, for me, control all four panels as the motor driver has two outs and both panels on one eave of my shed will move together.

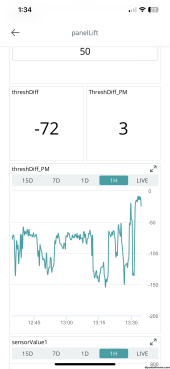

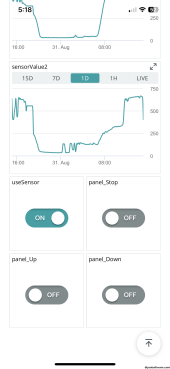

There will be at least another video when I move from a basic arduino nano to a IOT wifi version, where I’ll add the ability to move the panels via the Arduino cloud phone app, manually. The code needs some refinement as well.

Single Axis Solar Panel Tracker Arduino IOT powered!

Added two youtube shorts of on in operation, one up, one down. I think I’m going to add a small ramp of wood similar to what is in the vid as the stop for it. I added the metal strapping to hold the actuator down as well. It’s working well. The initial self tapping bolts pulled out of the aluminum crossbar, so I added cap head bolts through it into the actuator pivot. I’ll be bringing the wiring and almost finished Arduino electronics inside the shed.

Once I have some materials sorted it’ll be likely, around $100/panel, and then around $70-100 for the tracker electronics, which will, for me, control all four panels as the motor driver has two outs and both panels on one eave of my shed will move together.

There will be at least another video when I move from a basic arduino nano to a IOT wifi version, where I’ll add the ability to move the panels via the Arduino cloud phone app, manually. The code needs some refinement as well.

Single Axis Solar Panel Tracker Arduino IOT powered!

Added two youtube shorts of on in operation, one up, one down. I think I’m going to add a small ramp of wood similar to what is in the vid as the stop for it. I added the metal strapping to hold the actuator down as well. It’s working well. The initial self tapping bolts pulled out of the aluminum crossbar, so I added cap head bolts through it into the actuator pivot. I’ll be bringing the wiring and almost finished Arduino electronics inside the shed.

Last edited: