Murphyslaww

New Member

Been working on this for a while, and finally got it up and running in November. This has been pretty much to prove if you have an EV(Truck, or a little less so, car) and have as little as $5-6k available that you are ok with waiting on a 4-5 year return on, this is stupid easy.

Here is a link to the walkthrough on youtube which has the pricing of everything:

I'll be breaking how each part of the system was built in separate videos to come. We'll also be adding the raised bed garden salad gardens and likely be introducing some machine learning for panel angle to soil moisture sensing to growthrates for our mini-Agrivoltaic experiment.

It's 3.6kW of used longli 360watt panels from Santan Solar, a refurbished EG4 6000ex 48hv hybrid inverter from SignatureSolar, and currently, 10kW of powerqueen LiFePo4 batteries. The racking is two of the $140-160 Ecoworthy ground mount kits hacked, with some additional unistrut. We're still tweaking it, and will eventually try to make parts of it mobile for an Overlanding trailer buildout. (The batteries, subpanel, inverter, and charger)

The focus has been towards building it as cheaply as possible to attain payoff as soon as possible, which for us, means free fuel for our power-hungry, 2023 Ford Lighting. Right now, we think that could be as soon as 5 years. We've put in as much as 15kw in a day in winter sun, and will likely bump up to 20kW of batteries in the spring, as we expect we'll go over 20kW of available power in the spring through fall. This puts about 40-50 miles a day back into the Lightning. This type of trickle charging is great for the batteries, and we just have to remember to plug it in. We both work from home, so it's rare that we'll put more than 20 miles on it in a day anyway, but I'm going to be going back to the office every other week now for a day, and we have weekend trips to our farm, about 40 miles away.

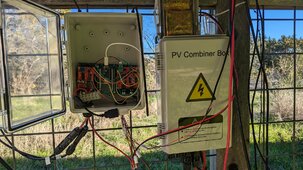

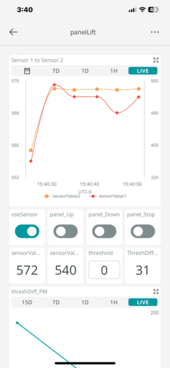

The system has single axis tracking, controlled with an Arduino Microcontroller, and light sensors, which we hope will produce 20% more output throughout the day, which should be a 2-3 year payoff for the tracking components themselves.

We've partnered with Progressive Automations in using their high-end Linear actuators, which are used as part of the ground mount racking. Their actuators have built-in Hall sensors, allowing synchronization of the 5 actuators, and setting wind and hail settings, positionally through sensors and software. This has not been implemented yet, as they actually just arrived and have just been installed and are tracking with fairly simple code, currently. It's been tested at as high as 50mph gusts, but it's likely the panels are not getting that much wind, this close to the house. The systems pivots are inset in the fences posts, which are in footings. We may add stanchions with more of the cinder footings on the other side, if it appears there is an issue.

Even with the addition of the tracking system, we're still at, about $4,000 after federal rebates for the project. Not bad for something that will eventually provide us with free fuel for the remaining life of the panels and batteries, which I'd guess would be at least 10-15 years.

With the ecoworthy actuators with only 14degrees of tilt either way

With the Progressive Automations actuators and the 100watt system power panel attached. These provide about 20 degrees of tilt, in moving from 18" to 24" actuators, and allowed direct mounting to the cinder footing brackets. It is all surprisingly sturdy.

Much beefier

EG4 and subpanel

Ford Chargestation Pro running at 12 amps, and our original Chargepoint set running at 32 amps for when we need a quicker fill up charge.

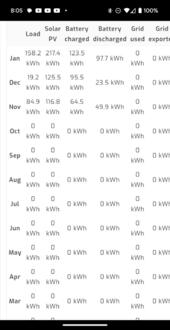

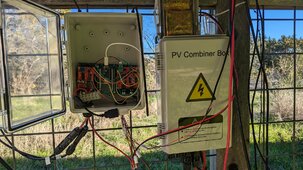

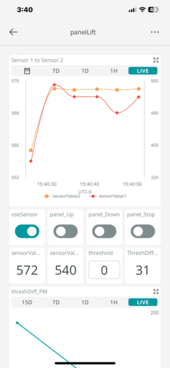

Control box for the tracking system. Far right is a board MPPT charge controller for the 100 watt panel that charges the battery on top of the combiner box, middle is an Arduino nano rp2040 connect. It will eventually have the controls for the Raised bed smartgarden watering system as well. Soil moisture sensors, and relays to run solenoids and pumping system. This is all controllable from the arduino cloud control app on my phone. Soon, there will be a sensor for wind speed as well, and panel angle:

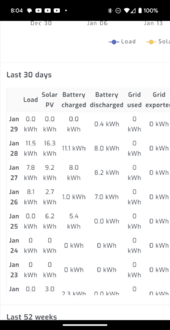

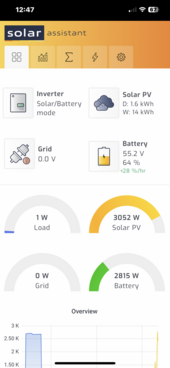

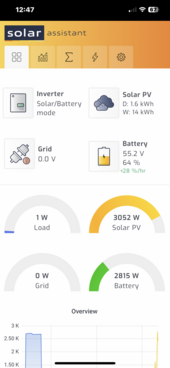

And of course, it's all monitored with SolarAssistant for output:

Here is a link to the walkthrough on youtube which has the pricing of everything:

I'll be breaking how each part of the system was built in separate videos to come. We'll also be adding the raised bed garden salad gardens and likely be introducing some machine learning for panel angle to soil moisture sensing to growthrates for our mini-Agrivoltaic experiment.

It's 3.6kW of used longli 360watt panels from Santan Solar, a refurbished EG4 6000ex 48hv hybrid inverter from SignatureSolar, and currently, 10kW of powerqueen LiFePo4 batteries. The racking is two of the $140-160 Ecoworthy ground mount kits hacked, with some additional unistrut. We're still tweaking it, and will eventually try to make parts of it mobile for an Overlanding trailer buildout. (The batteries, subpanel, inverter, and charger)

The focus has been towards building it as cheaply as possible to attain payoff as soon as possible, which for us, means free fuel for our power-hungry, 2023 Ford Lighting. Right now, we think that could be as soon as 5 years. We've put in as much as 15kw in a day in winter sun, and will likely bump up to 20kW of batteries in the spring, as we expect we'll go over 20kW of available power in the spring through fall. This puts about 40-50 miles a day back into the Lightning. This type of trickle charging is great for the batteries, and we just have to remember to plug it in. We both work from home, so it's rare that we'll put more than 20 miles on it in a day anyway, but I'm going to be going back to the office every other week now for a day, and we have weekend trips to our farm, about 40 miles away.

The system has single axis tracking, controlled with an Arduino Microcontroller, and light sensors, which we hope will produce 20% more output throughout the day, which should be a 2-3 year payoff for the tracking components themselves.

We've partnered with Progressive Automations in using their high-end Linear actuators, which are used as part of the ground mount racking. Their actuators have built-in Hall sensors, allowing synchronization of the 5 actuators, and setting wind and hail settings, positionally through sensors and software. This has not been implemented yet, as they actually just arrived and have just been installed and are tracking with fairly simple code, currently. It's been tested at as high as 50mph gusts, but it's likely the panels are not getting that much wind, this close to the house. The systems pivots are inset in the fences posts, which are in footings. We may add stanchions with more of the cinder footings on the other side, if it appears there is an issue.

Even with the addition of the tracking system, we're still at, about $4,000 after federal rebates for the project. Not bad for something that will eventually provide us with free fuel for the remaining life of the panels and batteries, which I'd guess would be at least 10-15 years.

With the ecoworthy actuators with only 14degrees of tilt either way

With the Progressive Automations actuators and the 100watt system power panel attached. These provide about 20 degrees of tilt, in moving from 18" to 24" actuators, and allowed direct mounting to the cinder footing brackets. It is all surprisingly sturdy.

Much beefier

EG4 and subpanel

Ford Chargestation Pro running at 12 amps, and our original Chargepoint set running at 32 amps for when we need a quicker fill up charge.

Control box for the tracking system. Far right is a board MPPT charge controller for the 100 watt panel that charges the battery on top of the combiner box, middle is an Arduino nano rp2040 connect. It will eventually have the controls for the Raised bed smartgarden watering system as well. Soil moisture sensors, and relays to run solenoids and pumping system. This is all controllable from the arduino cloud control app on my phone. Soon, there will be a sensor for wind speed as well, and panel angle:

And of course, it's all monitored with SolarAssistant for output:

Last edited: