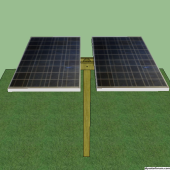

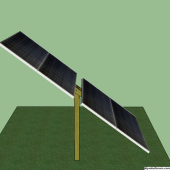

I've spent some time on designing the frame. These are bi-facial panels and I'm trying to keep the framing to a minimum. But I could use some input on both the design and material thickness.

The tracker/slew drive has flanges on each side that rotate to adjust the elevation/vertical.

Bolted to this flange, will be 2" OD (1/8" wall?) aluminum tubes protruding out each side.

The angle pieces the panels bolt to is 1"x3" for the two outers and 3"x3" for the center piece, all 3 are 1/8" thick aluminum.

I suppose I could use four 1"x3" pieces vs the current 3.

I am also considering sliding a tube inside (through the middle) and connecting the 2" pivot tubes to add some bracing/strength.

I guess the question is, do you think the design is strong enough?

Is 1/8" thick aluminum is a good choice?

The panels weigh 64 lbs/29kg each.

Wind loads here are low, it will see some protection by the fence, plus will park flat (below the fence line) when the wind gets too high.

That brings another question, any one have input on what wind speed should I park the tracker flat?

View attachment 150676

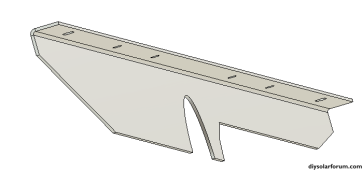

I slightly redesigned the end plates to show how they'd actually be built. I also added all the mounting holes for the panels.

View attachment 150677