heirloom hamlet

life my way

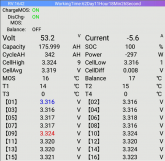

The guy in the video is still only playing around in the extreme bottom end of the charge of the cells.

He ought to put the packs on a float charge and just get every cell to 3.2V. Until that happens those bottom feeder cells are way past the point of usability.

He isn't really giving the float a chance to absorb when the cells are lower than 2.9V.

This is where taking the cover off and putting a single cell charger directly on the bottom cells will help.

The other way to get those very low cells up with the rest of the good ones is to do what DavePoz did and put every cell in parallel and passively just wait for a couple weeks until every cell is the same level.

Bulk charge to 53.3, float it at 52.9. And just sit there and wait while in float.

The overall voltage read at the big terminals is the AVERAGE of the cells. Those extremely low cells will take the voltage eventually. But don't forget, when there is a cell way lower than the average, there has to be some way more than the average.

If his(YouTube video) "dead cells" truly were dead they would not charge at all. They are taking charge. The cells just need a lot more juice and time.

52.9V = 3.309V per cell.

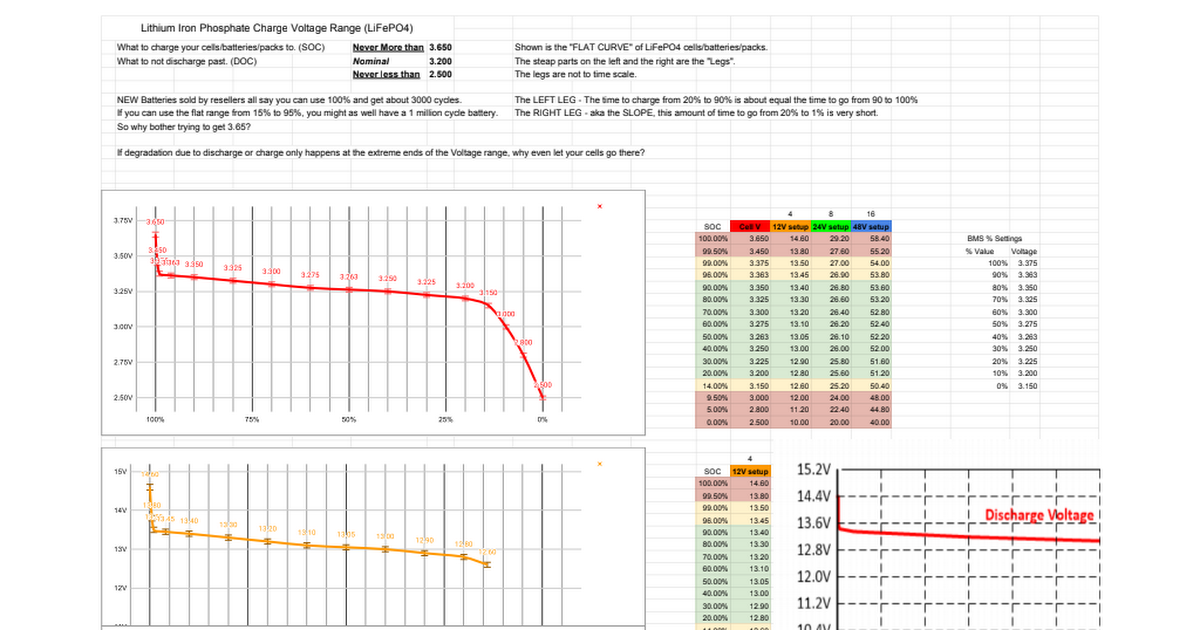

Lithium Iron Phosphave Charge Range

Sheet5 Lithium Iron Phosphate Charge Voltage Range (LiFePO4) What to charge your cells/batteries/packs to. (SOC),Never More than,3.650,Shown is the "FLAT CURVE" of LiFePO4 cells/batteries/packs. What to not discharge past. (DOC),Nominal,3.200,The steap parts on the left and the right are the "Le...docs.google.com

Okay, I trust you.

So, in my 24v case, I'm going to set Bulk to 26.6v (or 26.7?) and Float to 26.4 (or 26.5?), and wait. Let the sun rise, let the sun set. For a week, for a month, for a year... just wait.

Do I have that right?

What will be my sign when all cells are finally balanced and the battery is functioning as it can and should?