Michael B Caro

Solar Wizard

- Joined

- May 21, 2020

- Messages

- 1,194

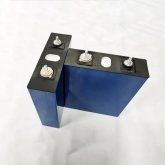

My supplier with your choice of M6 or M8 studs at no extra charge not only has Lishen 272ah,but also:

Lishen 202ah

Catl 202ah with QR code

Catl 271ah with QR code

and 310ah without QR code

Lishen 202ah

Catl 202ah with QR code

Catl 271ah with QR code

and 310ah without QR code