You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cheap chinese horizontal wind turbine, an in depth exploration.

- Thread starter brandnewb

- Start date

brandnewb

Going for serious. starting as newb

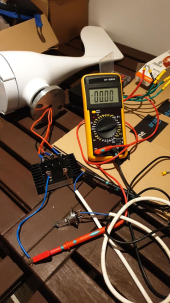

I meant this power meter that showed nothing while being in between the rectifier and the light bulb

The multi meter seems to work fine. Or do my results not make any sense?

I have a chaotic photo made real quick as I am now on diaper duty ;(

If it is not clear please ask more and I can do it tomorrow morning

Edit: the terminals were connected as on the image. For volts under load I used the 20 setting. For volt without load I used the 200 setting like it is on the picture

Edit2: ahh i did not change the terminals while testing Adc. that explains

The multi meter seems to work fine. Or do my results not make any sense?

I have a chaotic photo made real quick as I am now on diaper duty ;(

If it is not clear please ask more and I can do it tomorrow morning

Edit: the terminals were connected as on the image. For volts under load I used the 20 setting. For volt without load I used the 200 setting like it is on the picture

Edit2: ahh i did not change the terminals while testing Adc. that explains

Last edited:

brandnewb

Going for serious. starting as newb

i did not change the red probe before measuring amps . i'll do that first thing tomorow

brandnewb

Going for serious. starting as newb

Thanks. Sorry about me bugging you for pics. It saves so many questions.

So with everything connected like it is on the bottom pic, you spin the generator, the meter stays at 0? No jumping around? What happens when you change the knob down to the 20 amp AC setting and spin the generator again?

So with everything connected like it is on the bottom pic, you spin the generator, the meter stays at 0? No jumping around? What happens when you change the knob down to the 20 amp AC setting and spin the generator again?

brandnewb

Going for serious. starting as newb

you are not bugging me at all. you are a huge help and I am thankful for it.

the meter goes to 1.65

i just took the picture of the setup after I was done measuring. as i cant spin and take a picture at the same time

the meter goes to 1.65

i just took the picture of the setup after I was done measuring. as i cant spin and take a picture at the same time

brandnewb

Going for serious. starting as newb

DC amps

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,566

Wind turbines can be quite challenging to control.

The spec sheet says "-Brake method: electromagnetic'. This means it is up to you and the controller to maintain a sufficient electrical load to keep the unit from self destruction in strong winds. This usually means you need a load dump capable controller.

From first picture it looks like a permanent magnet alternator. This is similar to what is in inverter-generators. The thing about inverter-generators is the engine is limited to about 3800 rpm. A wind turbine can go crazy with enought wind. It just usually breaks the blades and self destructs if allowed to run away. The electrical load prevents this so if battery is fully charged you need a load dump controller to break load the wind turbine.

Two bad things can happen if wind is too great and it spins too fast. Already talked about mechanical destruction. Other issue is the voltage can get so high it blows out the rectifier diodes or controller. Letting it run too fast with little to no electrical load can result in very high voltage output. Most bridge rectifier packs for wind turbines have PIV breakdown rating greater than 1000v.

This unit may produce close to 400 vdc with no load at 3000 rpms, assuming the rectifiers PIV breakdown voltage is not exceeded.

A 1.3 meter diameter wind turbine well designed will produce a bit over 1 kW with 25 mph wind. 6 kW would require about 42 mph wind and likely alternator would burn up if production was very long time. 10 mph wind will be lucky to get 100 watts.

Generally you need fairly sustained wind >20 mph for wind turbines to be practical.

The voltage-current relationship is very complicated for a permanent magnet alternator involving rpm and load on alternator. A '48v' unit means its wire turns and gauge on stator are designed to give rated output power with proper load with about 48v at specified rpm. Without a load the voltage may be over twice the rated load voltage at same rpm. Of course without an electrical load the same wind will drive the rpm even higher resulting in even higher voltage.

This chart is for a '48vdc' PMA. Voltage is open circuit, current is short circuit output on this chart. Actual operational load VA is between these extremes.

The rectifiers and controller need to have enough overhead to take the higher voltage.

You may find some useful info at this site:

www.hydrogenappliances.com

www.hydrogenappliances.com

The spec sheet says "-Brake method: electromagnetic'. This means it is up to you and the controller to maintain a sufficient electrical load to keep the unit from self destruction in strong winds. This usually means you need a load dump capable controller.

From first picture it looks like a permanent magnet alternator. This is similar to what is in inverter-generators. The thing about inverter-generators is the engine is limited to about 3800 rpm. A wind turbine can go crazy with enought wind. It just usually breaks the blades and self destructs if allowed to run away. The electrical load prevents this so if battery is fully charged you need a load dump controller to break load the wind turbine.

Two bad things can happen if wind is too great and it spins too fast. Already talked about mechanical destruction. Other issue is the voltage can get so high it blows out the rectifier diodes or controller. Letting it run too fast with little to no electrical load can result in very high voltage output. Most bridge rectifier packs for wind turbines have PIV breakdown rating greater than 1000v.

This unit may produce close to 400 vdc with no load at 3000 rpms, assuming the rectifiers PIV breakdown voltage is not exceeded.

A 1.3 meter diameter wind turbine well designed will produce a bit over 1 kW with 25 mph wind. 6 kW would require about 42 mph wind and likely alternator would burn up if production was very long time. 10 mph wind will be lucky to get 100 watts.

Generally you need fairly sustained wind >20 mph for wind turbines to be practical.

The voltage-current relationship is very complicated for a permanent magnet alternator involving rpm and load on alternator. A '48v' unit means its wire turns and gauge on stator are designed to give rated output power with proper load with about 48v at specified rpm. Without a load the voltage may be over twice the rated load voltage at same rpm. Of course without an electrical load the same wind will drive the rpm even higher resulting in even higher voltage.

This chart is for a '48vdc' PMA. Voltage is open circuit, current is short circuit output on this chart. Actual operational load VA is between these extremes.

The rectifiers and controller need to have enough overhead to take the higher voltage.

You may find some useful info at this site:

Supercore PMA powercore pma ultracore pmg super core dual core Wind generators and turbines from home power and sustainable energy

DIY wind generators and solar panel grid tie systems kits off grid energy system

Last edited:

So under load (all DC measurements), 2.45 volts X 1.65 amps is 4.04 watts.

The problem is that light bulb. They take a bunch of power until they warm up. Normally this takes half a second to get warm as it pulls a bunch of power, but in this case, you don't have the power to warm it up.

The light is 2.5 ohms when cold, so when we put 48V to it (48v / 2.5 ohms = 19.2 amps X 48v = 921.6 watts) it will take 921.6 watts to get warmed up. It will blow shortly after since it's a 12v bulb running at 48v, but it will be brilliant for a bit. That generator is not making 921 watts for sure.

You will have much better luck with a small side light or tail light. 5-10 watts at most.

The problem is that light bulb. They take a bunch of power until they warm up. Normally this takes half a second to get warm as it pulls a bunch of power, but in this case, you don't have the power to warm it up.

The light is 2.5 ohms when cold, so when we put 48V to it (48v / 2.5 ohms = 19.2 amps X 48v = 921.6 watts) it will take 921.6 watts to get warmed up. It will blow shortly after since it's a 12v bulb running at 48v, but it will be brilliant for a bit. That generator is not making 921 watts for sure.

You will have much better luck with a small side light or tail light. 5-10 watts at most.

brandnewb

Going for serious. starting as newb

Ok I will look for smaller lights then. Also I will get my big drill out to play which is not in my garage at the moment but I can get it later today.

www.bosch-professional.com

www.bosch-professional.com

GSR 36VE-2-LI Cordless Drill/Driver | Bosch Professional

GSR 36VE-2-LI Cordless drills/drivers | Delivers a hard torque of 100 Nm, making it ideal even for the toughest applications, KickBack Control for increased user protection, convenient tool handling, and perfect control, Electronic Motor Protection protects the motor against overload and ensures...

| Torque (soft/hard/max.) | 60/100/- Nm |

| No-load speed (1st gear / 2nd gear) | 0 – 420 / 0 – 1,800 rpm |

| Chuck capacity, min./max. | 1.5 / 13 mm |

| Battery voltage | 36 V |

| Torque settings | 25+1 |

brandnewb

Going for serious. starting as newb

I can order a few smaller car lights. 12v 5w, 12v 10w and 24v 10w. 48v lights with low wattage I did not find yet.

I have asked before but can't find the answer or I did not understand it so please allow me to ask again.

Can I hook up those lights in series and in parallel? Will 2 x 12v 5 watt lights in series result in a load of 12v 10w?

And what would the resulting load be if I hook up 2 x 12v 5w lights in parallel?

I have asked before but can't find the answer or I did not understand it so please allow me to ask again.

Can I hook up those lights in series and in parallel? Will 2 x 12v 5 watt lights in series result in a load of 12v 10w?

And what would the resulting load be if I hook up 2 x 12v 5w lights in parallel?

brandnewb

Going for serious. starting as newb

Just in, breaking news. all the headlines read.

I've got half a mind to start winding my own alternator. As I think even 315 rpm is way too fast to be save for a turbine to spin in an urban setting

winding resistance (Ohm) | | | | |

| leads | | | |

| | a | b | 44.1 |

| | c | b | 49.5 |

| | a | c | 49.5 |

Rpm +- 315 | no load | | | |

Alternating Current, measured with the Aac at 200m setting | | | | |

| leads | | | |

| | a | b | 5.6 |

| | c | b | 5.1 |

| | a | c | 5.5 |

| | | | |

Vac | | | | |

| leads | | | |

| | a | b | 26.2 |

| | c | b | 24.3 |

| | a | c | 26 |

| | | | |

Vdc | | | | 34.3 |

| | | | |

Direct Current, measured with the Adc at 200m setting | | | | 8.3 |

I've got half a mind to start winding my own alternator. As I think even 315 rpm is way too fast to be save for a turbine to spin in an urban setting

Short_Shot

Solar Addict

- Joined

- Jul 13, 2021

- Messages

- 1,823

This is interesting to me, so commenting for updates.

I wonder how much load force is applied parallel to the shaft at rated load and wind speed.

I've got a rather tall TV antenna out back from the good old days that's virtually useless since I don't watch broadcast TV. However it might be a great spot to stick a small wind generator to keep my fridge and freezer running on a smallish battery.

Even if it's a bit much for the tower I could always anchor 3 cables if I really needed to. Then I could toss a couple small solar panels up there too.

Of course... I have a generator and power outages here are very rare so it's never been a real issue prompting a need.

I wonder how much load force is applied parallel to the shaft at rated load and wind speed.

I've got a rather tall TV antenna out back from the good old days that's virtually useless since I don't watch broadcast TV. However it might be a great spot to stick a small wind generator to keep my fridge and freezer running on a smallish battery.

Even if it's a bit much for the tower I could always anchor 3 cables if I really needed to. Then I could toss a couple small solar panels up there too.

Of course... I have a generator and power outages here are very rare so it's never been a real issue prompting a need.

brandnewb

Going for serious. starting as newb

Thanks @RCinFLA for your contribution. However I was unable to find useful information there while quickly browsing. I must admit that I did not analyze the information there because alarm bells went off in my head warning me this could be a sales pitch leading no where.Wind turbines can be quite challenging to control.

The spec sheet says "-Brake method: electromagnetic'. This means it is up to you and the controller to maintain a sufficient electrical load to keep the unit from self destruction in strong winds. This usually means you need a load dump capable controller.

From first picture it looks like a permanent magnet alternator. This is similar to what is in inverter-generators. The thing about inverter-generators is the engine is limited to about 3800 rpm. A wind turbine can go crazy with enought wind. It just usually breaks the blades and self destructs if allowed to run away. The electrical load prevents this so if battery is fully charged you need a load dump controller to break load the wind turbine.

Two bad things can happen if wind is too great and it spins too fast. Already talked about mechanical destruction. Other issue is the voltage can get so high it blows out the rectifier diodes or controller. Letting it run too fast with little to no electrical load can result in very high voltage output. Most bridge rectifier packs for wind turbines have PIV breakdown rating greater than 1000v.

This unit may produce close to 400 vdc with no load at 3000 rpms, assuming the rectifiers PIV breakdown voltage is not exceeded.

A 1.3 meter diameter wind turbine well designed will produce a bit over 1 kW with 25 mph wind. 6 kW would require about 42 mph wind and likely alternator would burn up if production was very long time. 10 mph wind will be lucky to get 100 watts.

Generally you need fairly sustained wind >20 mph for wind turbines to be practical.

The voltage-current relationship is very complicated for a permanent magnet alternator involving rpm and load on alternator. A '48v' unit means its wire turns and gauge on stator are designed to give rated output power with proper load with about 48v at specified rpm. Without a load the voltage may be over twice the rated load voltage at same rpm. Of course without an electrical load the same wind will drive the rpm even higher resulting in even higher voltage.

This chart is for a '48vdc' PMA. Voltage is open circuit, current is short circuit output on this chart. Actual operational load VA is between these extremes.

The rectifiers and controller need to have enough overhead to take the higher voltage.

You may find some useful info at this site:

Supercore PMA powercore pma ultracore pmg super core dual core Wind generators and turbines from home power and sustainable energy

DIY wind generators and solar panel grid tie systems kits off grid energy systemwww.hydrogenappliances.com

In case that link does provide actual schematics of efficient magneto's (power producing alternators (yes I keep reading more and more about the topic

brandnewb

Going for serious. starting as newb

I found a 500watt corded drill just now, that has been hiding for years, in my garage. So no need to go out and get my big bosch.

this corded drill can spin at +-3100 rpm just in the hand.

Is this useful to be able to dive deeper into this turbine?

I am still very much wanting to know what will happen when I connect loads in series and/or in parallel. Can anybody shine a light on that?

this corded drill can spin at +-3100 rpm just in the hand.

Is this useful to be able to dive deeper into this turbine?

I am still very much wanting to know what will happen when I connect loads in series and/or in parallel. Can anybody shine a light on that?

brandnewb

Going for serious. starting as newb

These are what I got yesterdayFYI, If you ordered that model I listed, caps in that size all come with terminals designed to be soldered to a PCB, or mounted in a holder that Amazon does not seem to stock. So you will need to solder some wires to the terminals.

I think I can clamp wires on the feeble pins or should I get a soldering station?

Anyway, how do I use those capacitors actually in the context of testing this turbine?

Last edited:

RCinFLA

Solar Wizard

- Joined

- Jun 21, 2020

- Messages

- 3,566

Putting 63v electrolytics on output of PMA is not a good idea. You will likely blow them out due to overvoltaging.Anyway, how do I use those capacitors actually in the context of testing this turbine?

If you are trying to supply the initial surge current to run an incandescent bulb this will not help. The rpm to keep unloaded output below 63v will not likely sustain the bulb's normal run current. The voltage will collapse when bulb run load applied (or capacitor discharge will blow out bulb) unless you quickly increase rpm. If you then turn off the bulb the voltage will quickly rise above capacitor voltage rating. You will likely either blow out the bulb, the capacitor, or both.

If you want to play with PMA with a power drill drive, get a DL24P load tester. It allows you to control constant current, constant voltage limit, constant power limit, and constant resistance. You can do load profiles vs rpm up to about 130 watt limit of load tester.

For a PMA, for a given load, the output voltage is proportional to rpm. At a given rpm the voltage will drop and current will increase as load is increased. RPM x torque drive = power = output voltage x current. Torque is the variable that is not easy to measure. It must be deduced from load output power divided by rpm. You also need a way measure drill's rpm's. There is also efficiency losses but the relationship holds,.

Your picture of wire twisted on terminals is scary. At least get alligator clips to make connections. Any intermittant connections will cause high inductive voltage spikes. It can damage the bridge rectifier.

If you are old enough to remember the bicycle light generators that rubbed against the side of the bike tire, it is just like that. The faster you peddled the brighter the light got.

Last edited:

brandnewb

Going for serious. starting as newb

having read up on the topic regarding winding, one could also say that the windings in this particular unit are poorly done (I have pictures in the OP). That could well explain the inconsistent values I have over the 3 phases.

I already know that this alternator is going no where for me so I intend to actually cut it up as to be able to make a schematic representation of it and which can serve as a how to NOT do it for others.

for others.

I already know that this alternator is going no where for me so I intend to actually cut it up as to be able to make a schematic representation of it and which can serve as a how to NOT do it

brandnewb

Going for serious. starting as newb

Yeah unless someone sets me straight and then there might be hope yet of course

brandnewb

Going for serious. starting as newb

Is there anyone that can shine some light on this please?I can order a few smaller car lights. 12v 5w, 12v 10w and 24v 10w. 48v lights with low wattage I did not find yet.

I have asked before but can't find the answer or I did not understand it so please allow me to ask again.

Can I hook up those lights in series and in parallel? Will 2 x 12v 5 watt lights in series result in a load of 12v 10w?

And what would the resulting load be if I hook up 2 x 12v 5w lights in parallel?

chrisski

Solar Boondocker

- Joined

- Aug 14, 2020

- Messages

- 5,476

Take a look at this:

Three 40 watt builds in parallel shine normally and draw 120 watts. Put the same three bulbs in series and they only pull 13 watts and shine much less brightly.

If you’re asking if you can order four 12 volt bulbs and put them in series to make one 48 volt bulb, I don’t know for sure. Someone told me for his 24 volt circuit he put two 12 volt LEDs in series to make a single 24 volt LED without having to find more expensive and hard to find in RV stores LEDs. I have not tried it myself, and incandescents work differently than LEDs he used.

Three 40 watt builds in parallel shine normally and draw 120 watts. Put the same three bulbs in series and they only pull 13 watts and shine much less brightly.

If you’re asking if you can order four 12 volt bulbs and put them in series to make one 48 volt bulb, I don’t know for sure. Someone told me for his 24 volt circuit he put two 12 volt LEDs in series to make a single 24 volt LED without having to find more expensive and hard to find in RV stores LEDs. I have not tried it myself, and incandescents work differently than LEDs he used.

brandnewb

Going for serious. starting as newb

In light (pun intended) of the above. My brain is not capable yet of devising a strategy to get to a realistic power output of the horizontal turbine at safe urban speeds.

I will ask on a physics/electro forum and will keep you guys updated of what I learn

I will ask on a physics/electro forum and will keep you guys updated of what I learn

Similar threads

- Replies

- 3

- Views

- 702

- Replies

- 52

- Views

- 3K

- Replies

- 1

- Views

- 443

- Replies

- 19

- Views

- 1K